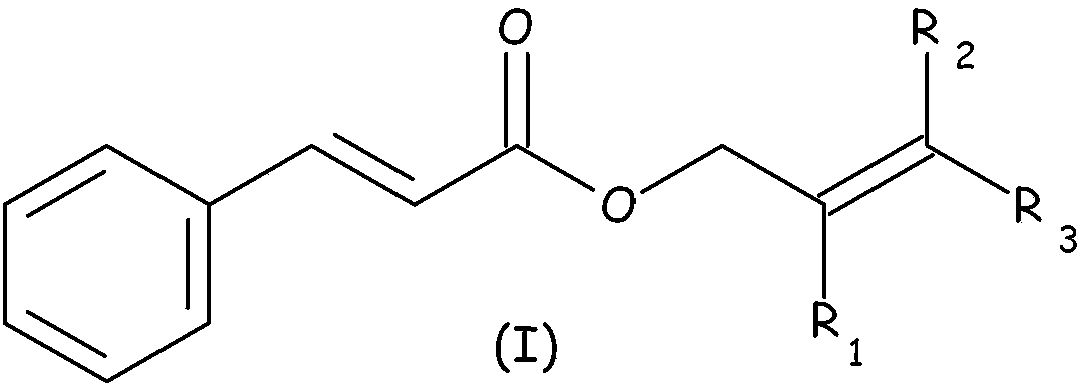

Vinylidene chloride polymer composition comprising at least one allyl cinnamate

A technology of vinylidene chloride and cinnamate, which is applied to special packaging items, packaging item types, packaging, etc., and can solve problems such as seldom use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The following reagents were used in these examples:

[0080] Masterbatch (M / B) of PVDC composition: VDC / MA copolymer having a VDC / MA weight ratio of 92 / 8, commercially available as PV910TAX5A-24-01, and containing trace amounts of additives (from Solvay Company (Solvay));

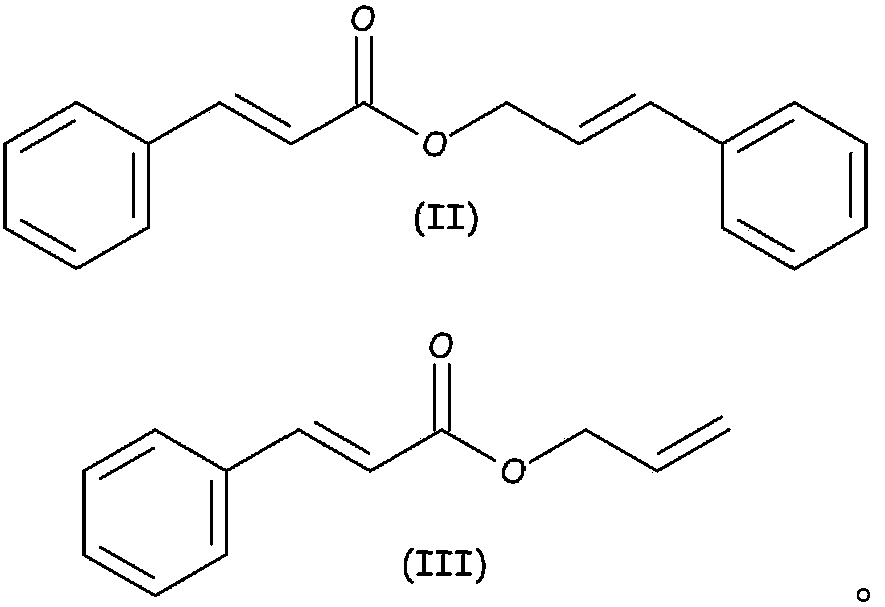

[0081] Dienophiles (both available from Aldrich);

[0082] Methyl trans-cinnamate (CAS No. 1754-62-7; purity 99%);

[0083] Ethyl trans-cinnamate (CAS No. 103-36-6; purity 99%);

[0084] Cinnamyl cinnamate (CAS No. 122-69-0; purity ≥ 95%);

[0085] Allyl cinnamate (CAS No. 1866-31-5; purity ≥99%).

[0086] Fabrication of PVDC monolayers incorporating different dienophiles:

[0087] 98wt% of the PVDC composition incorporating 2wt% of different dienophiles was injected by using an extruder (D=19mm, L / D ratio of the screw=20) with a sheet die of 200x0.6mm M / B extrusion to produce monolayer films of PVDC compositions. Upon exiting the die, the films were cooled to be quenched and stretched to a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com