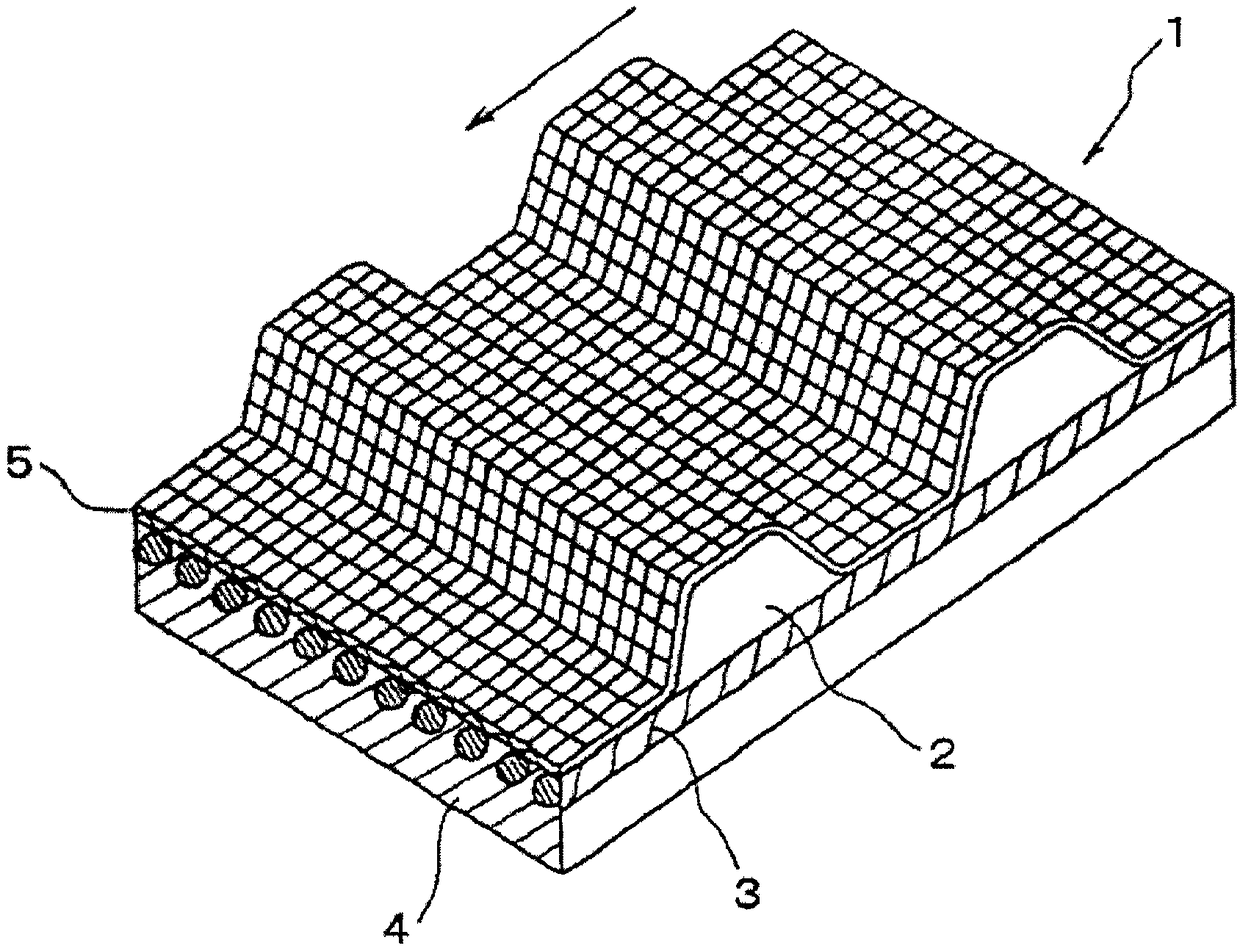

Transmission belt

A technology for transmission belts and rubber layers, applied in the field of transmission belts, can solve the problems of reduced durability of toothed belts, less carbon black ratio, peeling, etc., and achieve the effects of inhibiting peeling, improving wear resistance and modulus, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~6

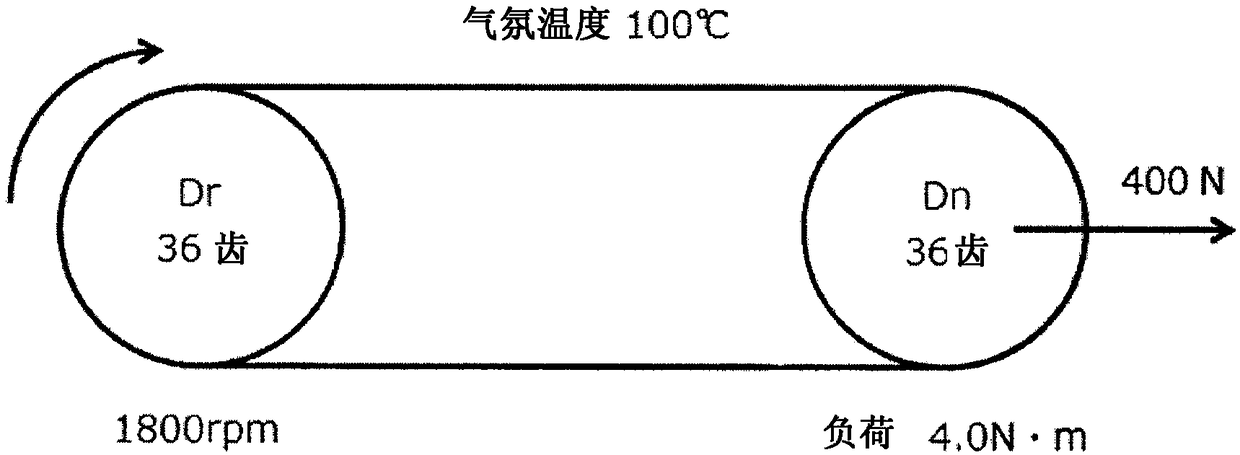

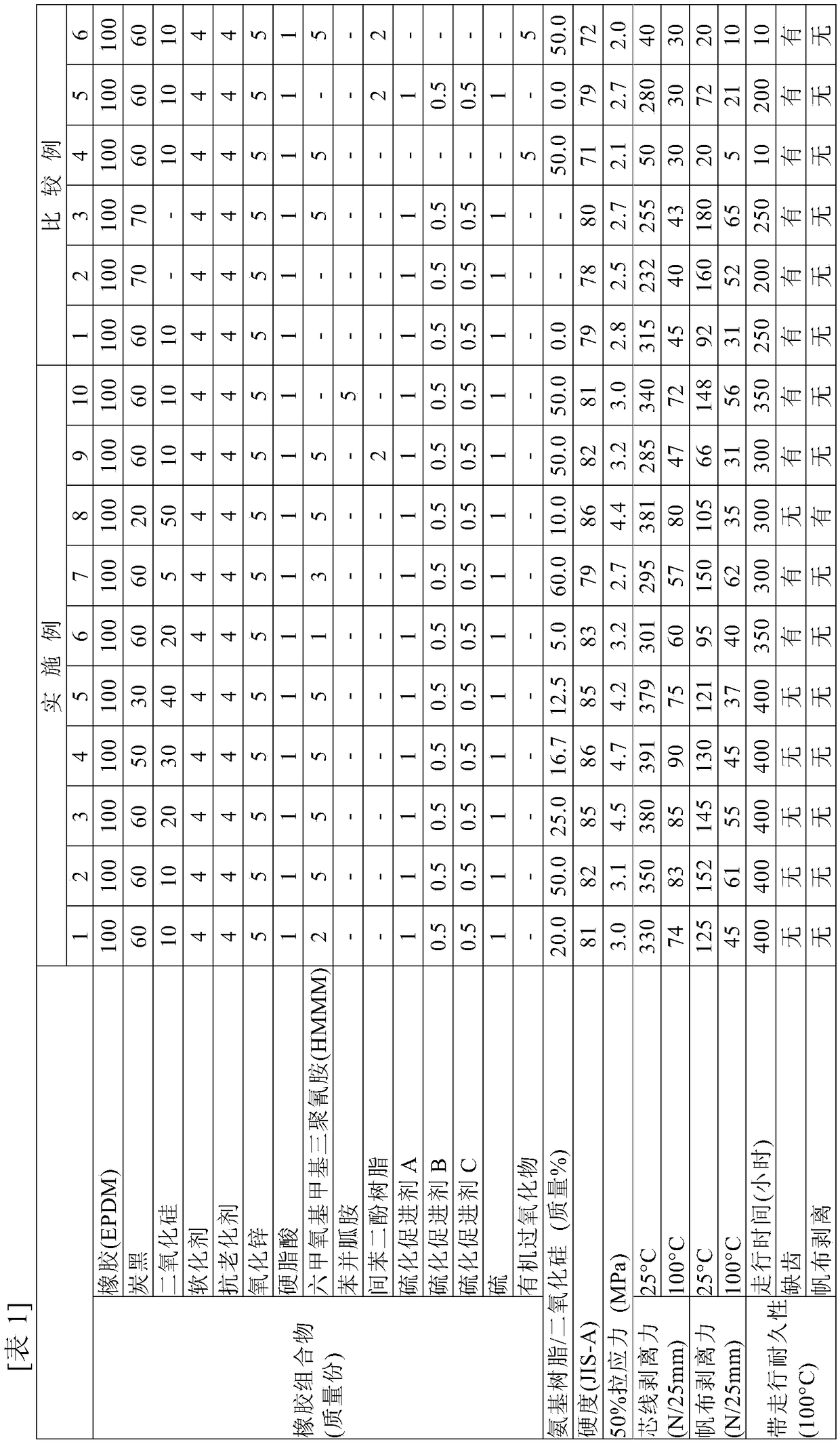

[0116] The rubber composition shown in Table 1 was used to prepare samples, and the results of evaluations of hardness and 50% tensile stress, core wire peeling force, canvas peeling force, and carry-over durability are shown in Table 1.

[0117]

[0118] From the results of Table 1, it can be judged that the transmission belts of Examples 1 to 10 have reached a traveling time of 300 hours or more, and have practically sufficient durability.

[0119] It should be noted that in Example 6, the mass ratio of the melamine resin to the silica was as low as 5% by mass, and the tooth loss failure occurred when the traveling time was 350 hours.

Embodiment 7

[0120] Example 7 is under the condition that the mass ratio of the melamine resin to the silica is as high as 60% by mass, and the tooth loss failure occurs after 300 hours.

[0121] In addition, in Example 8, under the conditions that the compounding amount of silica was as high as 50 parts by mass and the compounding amount of carbon black was as little as 20 parts by mass, the cover fabric peeling failure occurred after 300 hours.

[0122] In addition, Example 9 was a condition in which a resorcinol resin was added, and a tooth loss failure occurred at 300 hours. In contrast, in Example 2 where the resorcinol resin was not added, the belt ran for 400 hours without failure. Therefore, it can be judged that the addition of the resorcinol resin does not contribute to the improvement of durability.

[0123] In addition, Example 10 was a condition containing a guanamine resin as an amino resin, and compared with Comparative Example 1, an increase in hardness and tensile stress was obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com