Concrete admixture, preparation method, using method and application

A concrete admixture and water reducing agent technology, applied in the field of concrete admixtures, can solve the problems of increased cost of concrete engineering, expansion of admixture shortcomings, compatibility of different admixtures, etc., to overcome concrete shrinkage cracking, improve segregation problems and The problem of liquidity loss and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

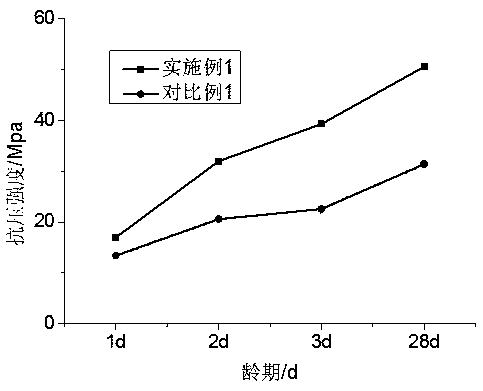

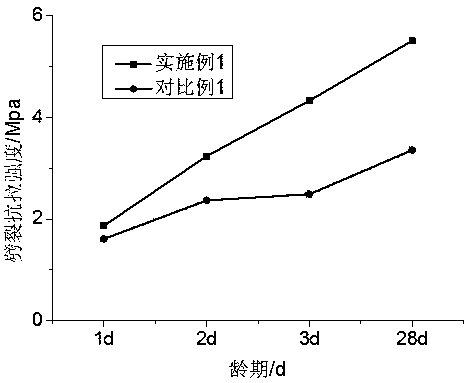

Embodiment 1

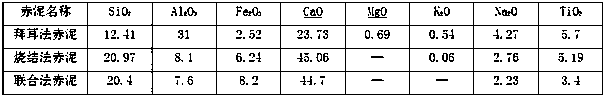

[0030] In this example, red mud, fly ash, silica fume, sodium gluconate, and polycarboxylate water reducer are activated to obtain the mixture, and 5% of the mixture is added according to the mass ratio of the cementitious material during the concrete mixing process. .

[0031] The quality of each raw material of the admixture is as follows: 5 kg of Bayer process red mud, 5 kg of fly ash, 0.5 kg of silica fume, 1 kg of sodium gluconate, and 0.5 kg of polycarboxylate superplasticizer.

[0032] A method for preparing a concrete admixture: (1) Preliminary crushing: firstly, the alumina industrial waste slag red mud is preliminarily crushed in a crusher to meet the feed size requirement of a ball mill. (2) Drying: Put the preliminarily crushed red mud into a dryer at 100°C to the rated temperature and hold the temperature for 3 hours until it reaches a constant weight. (3) Grinding: Grind the dried red mud to 400 mesh in a ball mill, and sieve it with a 0.045mm sieve. The sieving...

Embodiment 2

[0041] In this example, red mud, fly ash, silica fume, sodium gluconate, and naphthalene-based water reducer were activated to obtain the mixture, and 1% of the mixture was added according to the mass ratio of the cementitious material during the concrete mixing process.

[0042] The quality of each raw material of the admixture is as follows: 6 kg of Bayer process red mud, 3 kg of fly ash, 1 kg of silica fume, 0.5 kg of sodium gluconate, and 2 kg of naphthalene-based water reducer.

[0043] A method for preparing a concrete admixture: (1) Preliminary crushing: firstly, the alumina industrial waste slag red mud is preliminarily crushed in a crusher to meet the feed size requirement of a ball mill. (2) Drying: Put the preliminarily crushed red mud into a dryer at 600°C to the rated temperature and hold the temperature for 1 hour to constant weight. (3) Grinding: Grind the dried red mud to 200 mesh in a ball mill, and sieve it with a 0.045mm sieve. The sieving rate is required t...

Embodiment 3

[0052] In this example, red mud, fly ash, silica fume, sodium gluconate, and sulfamate water reducer are activated to obtain the mixture, and 9% of the mixture is added according to the mass ratio of the cementitious material during the concrete mixing process. material.

[0053] The quality of each raw material of the admixture is as follows: Bayer process red mud 7kg, fly ash 2kg, silica fume 1kg, sodium gluconate 0.5kg, sulfamate superplasticizer 0.5 kg.

[0054] A method for preparing a concrete admixture: (1) Preliminary crushing: firstly, the alumina industrial waste slag red mud is preliminarily crushed in a crusher to meet the feed size requirement of a ball mill. (2) Drying: Put the preliminarily crushed red mud into a dryer at 300°C to the rated temperature and hold the temperature for 1.5 hours to constant weight. (3) Grinding: Grind the dried red mud to 250 mesh in a ball mill, and sieve it with a 0.045mm sieve. The sieving rate is required to reach 80%, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com