A self-healing superamphiphobic and photocatalytic dual self-cleaning coating and its preparation method

A self-cleaning coating, super-amphiphobic technology, applied in coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve the problem of low coating life, narrow coating application area, self-cleaning ability problems such as failure, to achieve the effect of simple and easy preparation method, excellent superoleophobic performance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

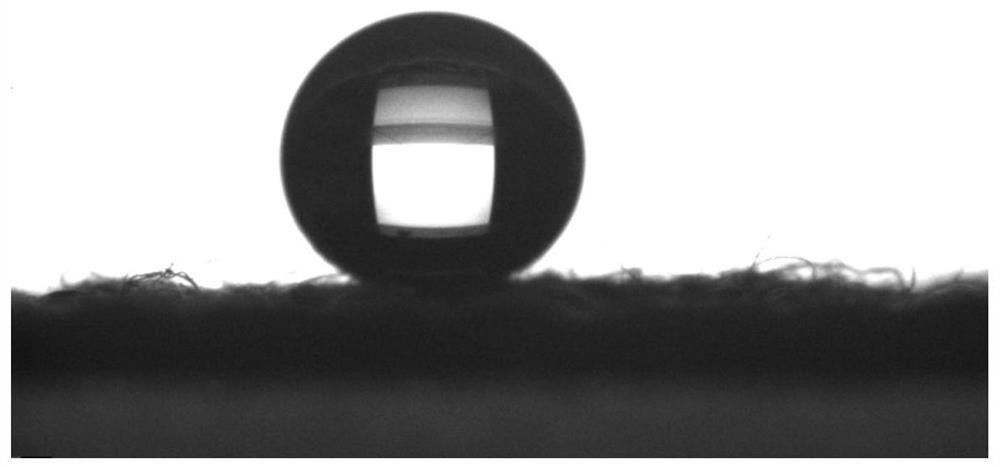

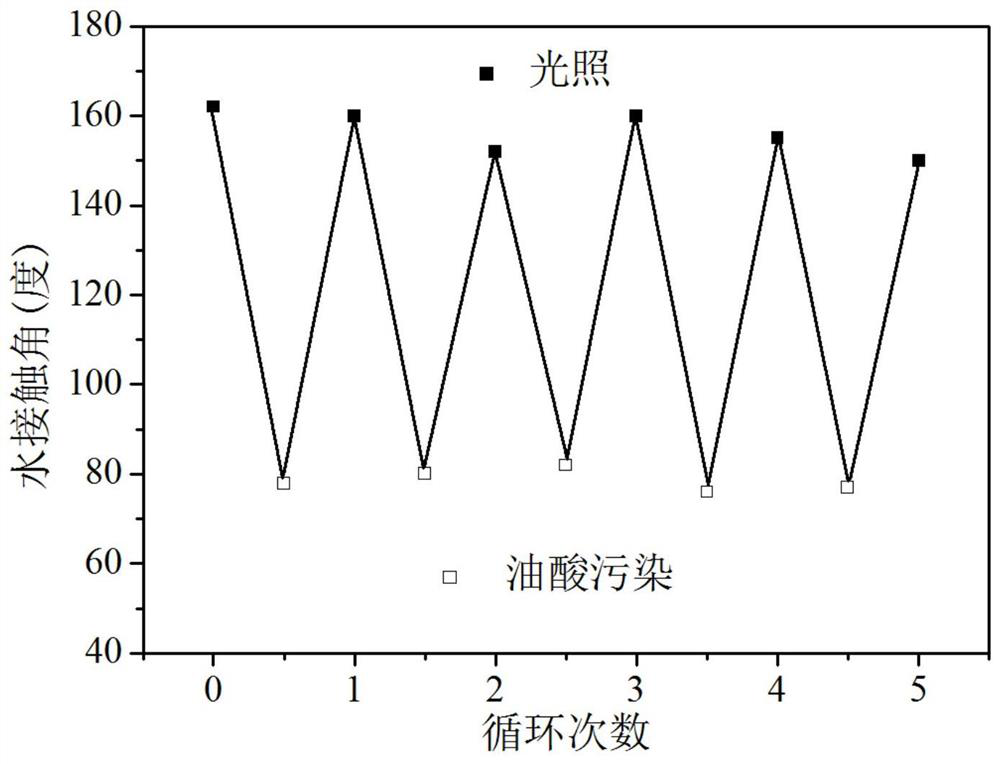

[0038] In this example, the self-healing superamphiphobic and photocatalytic double self-cleaning coating is formed by coating the surface of cotton fabric with a mixed solution containing F-POSS and photocatalytic particles; the photocatalytic particles are titanium dioxide particles, and the photocatalytic particles are mixed with The mass ratio of F-POSS is 1;

[0039] F-POSS is prepared from fluorine-containing siloxane as a precursor; fluorine-containing siloxane is 1H, 1H, 2H, 2H-tridecafluorooctyltriethoxysilane;

[0040] The mixed solution is formed by dispersing F-POSS and titanium dioxide photocatalytic particles in a fluorine-containing solvent, which also contains other micro / nano particles; the mass ratio of other micro / nano particles to F-POSS is 1.

[0041] Other micro / nano particles are polytetrafluoroethylene particles.

[0042] The fluorine-containing solvent is DuPont Capstone ST-110 fluorocarbon surfactant.

[0043] The preparation method of the self-healin...

Embodiment 2

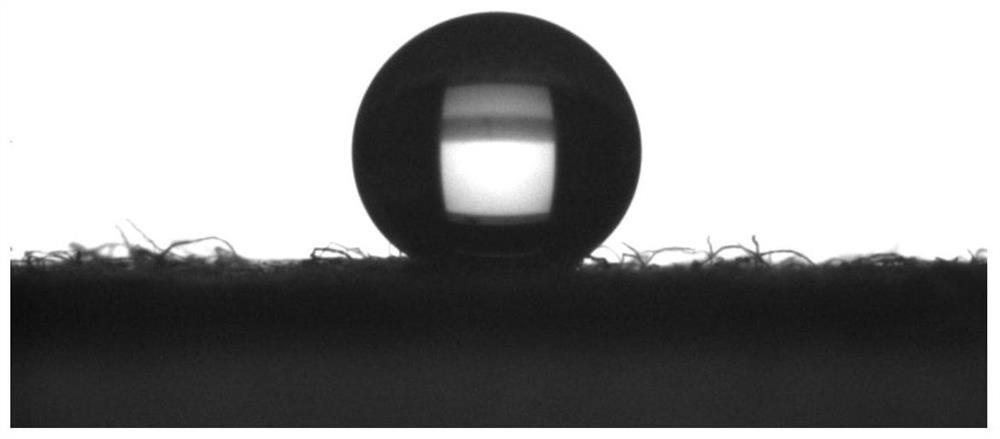

[0054] In this example, the self-healing superamphiphobic and photocatalytic double self-cleaning coating is formed by coating the surface of polyester fabric with a mixed solution containing F-POSS and photocatalytic particles; the photocatalytic particles are titanium dioxide particles, and the photocatalytic particles are mixed with The mass ratio of F-POSS is 2;

[0055] F-POSS is prepared from fluorine-containing siloxane as a precursor; fluorine-containing siloxane is 1H, 1H, 2H, 2H-heptadecafluorodecyltrimethoxysilane;

[0056] The mixed solution is formed by dispersing F-POSS and titanium dioxide photocatalytic particles in a fluorine-containing solvent;

[0057] The fluorine-containing solvent is DuPont Capstone ST-300 fluorocarbon surfactant.

[0058] The preparation method of the self-healing superamphiphobic and photocatalytic dual self-cleaning coating is as follows:

[0059] Step 1. Preparation of F-POSS:

[0060] Dissolve the fluorine-containing silicone 1H, ...

Embodiment 3

[0069] In this example, the self-healing superamphiphobic and photocatalytic double self-cleaning coating is formed by coating the glass surface with a mixed solution containing F-POSS and photocatalytic particles; the photocatalytic particles are titanium dioxide particles, and the photocatalytic particles are combined with F-POSS - The mass ratio of POSS is 4;

[0070] F-POSS is prepared from fluorine-containing siloxane as a precursor; fluorine-containing siloxane is 1H, 1H, 2H, 2H-heptadecafluorodecyltrimethoxysilane;

[0071] The mixed solution is formed by dispersing F-POSS and titanium dioxide photocatalytic particles in a fluorine-containing solvent, which also contains other micro / nano particles; the mass ratio of other micro / nano particles to F-POSS is 5.

[0072] Other micro / nano particles are polytetrafluoroethylene particles.

[0073] The fluorinated solvent is 2H,3H-perfluoropentane.

[0074] The preparation method of the self-healing superamphiphobic and photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com