A kind of preparation method of transparent super-amphiphobic material

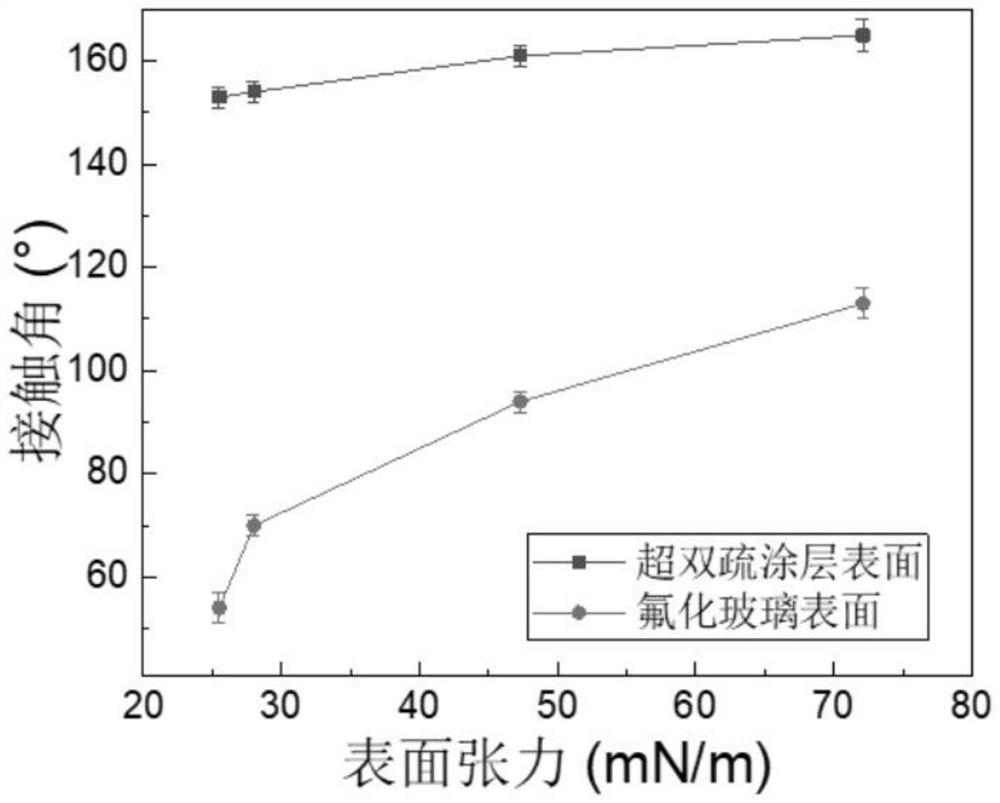

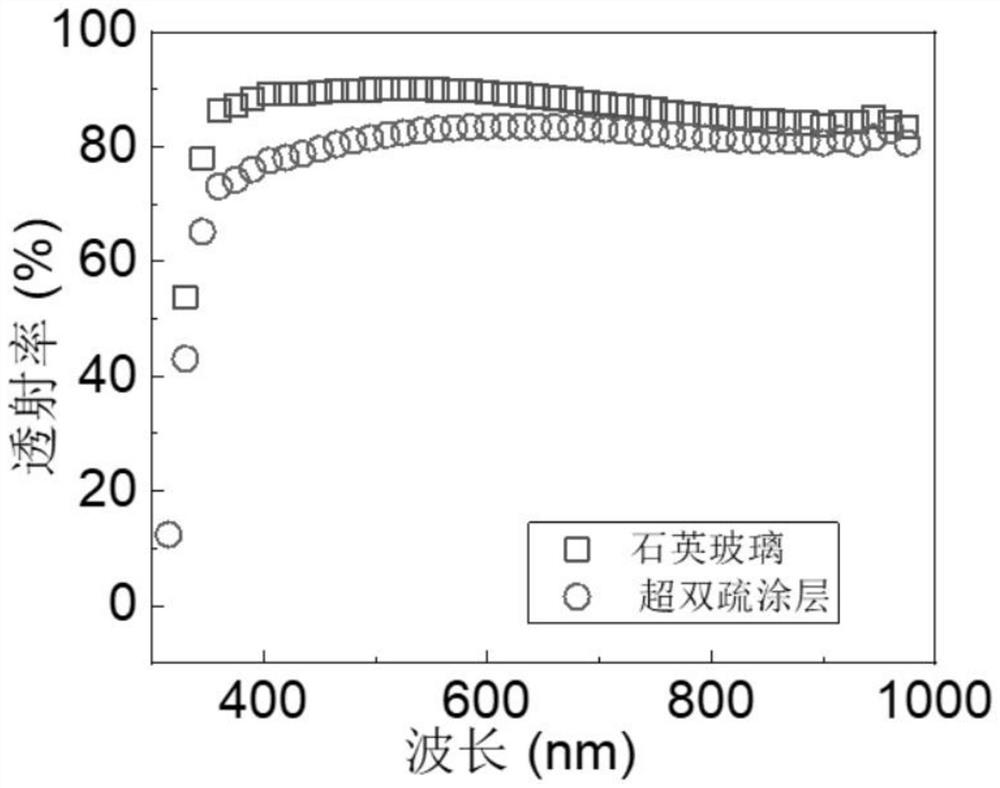

A super-amphiphobic and transparent technology, applied in the field of preparation of transparent super-amphiphobic materials, can solve the problems of poor oil resistance of transparent coatings, achieve good thermal and mechanical stability, strong operability, and easy preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

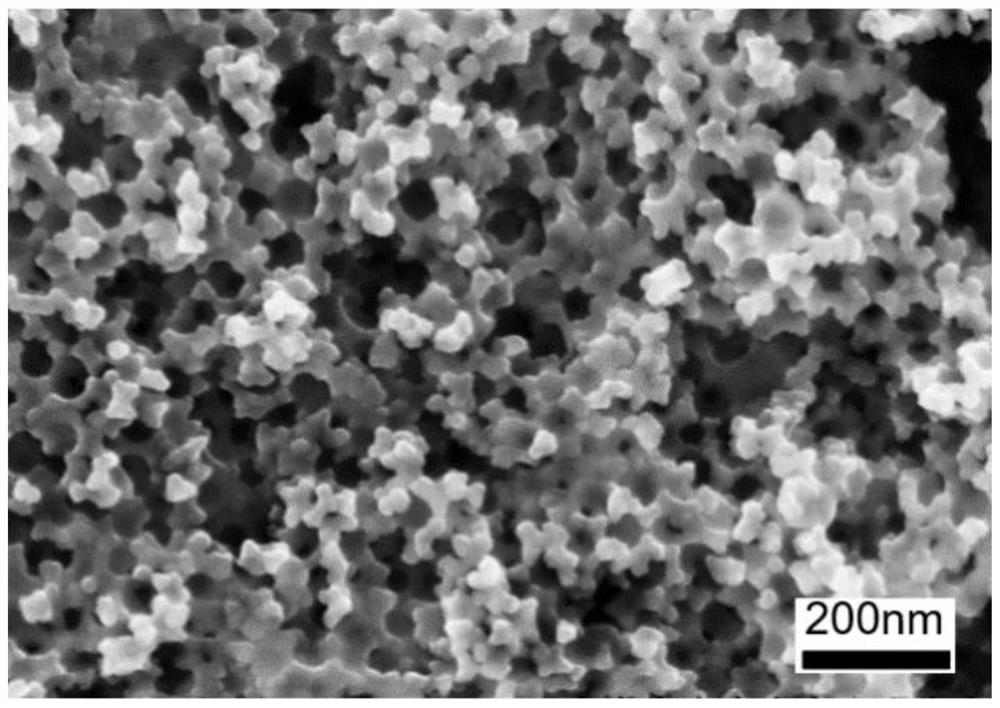

[0034] The preparation of embodiment 1 transparent super-amphiphobic coating

[0035] (1) Using water as a solvent, a 50nm monodispersed polystyrene microsphere emulsion is prepared into a liquid A with a mass concentration of 5%;

[0036] (2) Mix 0.2g of ethyl orthosilicate, 0.2g of 0.1mol / L hydrochloric acid, and 0.3g of absolute ethanol in the sample bottle to prepare liquid B;

[0037] (3) 5g of deionized water and 0.2g of B solution were added to 1g of solution A, followed by continuous stirring for 45min in a magnetic stirrer, and a partially hydrolyzed and cross-linked polystyrene sol-gel prepolymer solution was obtained after stirring. The bulk solution was ultrasonically dispersed (100W) for 15 minutes to prepare a transparent super-amphiphobic coating;

[0038](4) Spray the obtained transparent super-amphiphobic coating on the surface of the glass substrate: place the super-amphiphobic coating (ie, the prepolymer solution after ultrasonic dispersion) under a pressur...

Embodiment 2

[0048] The preparation of embodiment 2 transparent super-amphiphobic coating

[0049] The preparation method is the same as that of Example 1, and the difference from Example 1 is that: liquid A is a 50 nm monodispersed polystyrene microsphere solution with a mass concentration of 0.1%.

[0050] The test results of scanning electron microscope, wettability, transmittance, heat resistance test, friction resistance and other test results are consistent with those of Example 1.

Embodiment 3

[0051] The preparation of embodiment 3 transparent super-amphiphobic coating

[0052] The difference from Example 1 is that: Liquid A is a 50 nm monodispersed polystyrene microsphere solution with a mass concentration of 10%.

[0053] The test results of scanning electron microscope, wettability, transmittance, heat resistance test, friction resistance and other test results are consistent with those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com