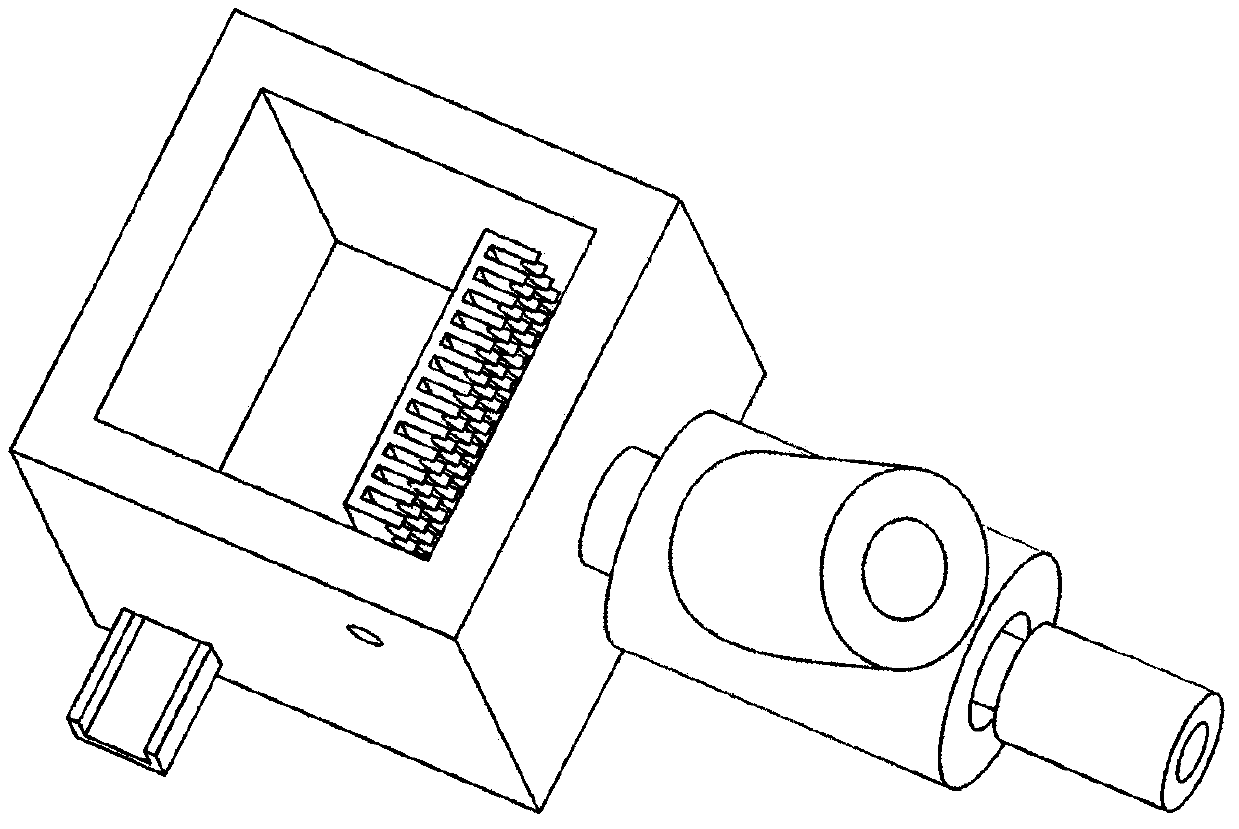

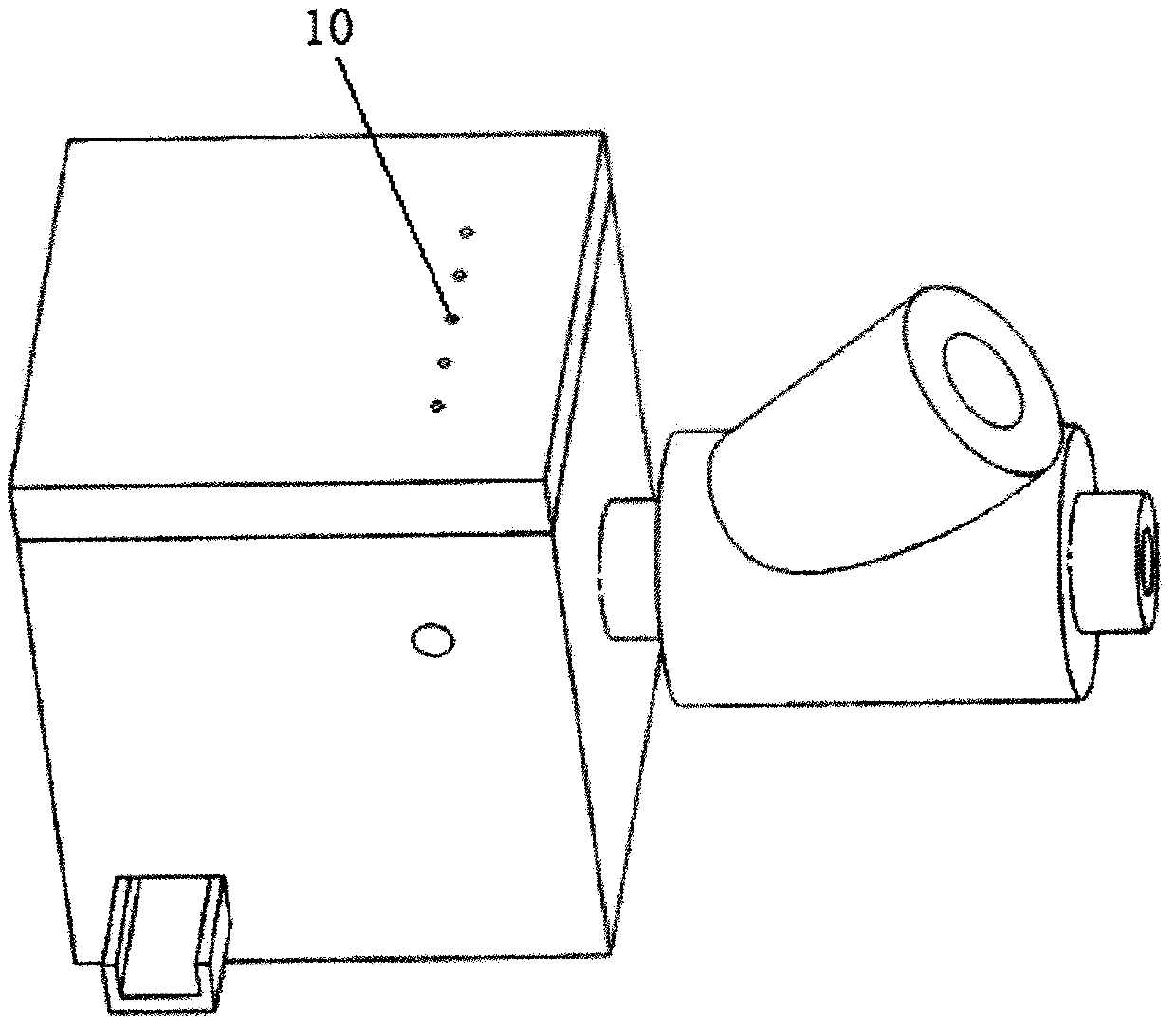

A microstructure device for physical cell crushing and its cell crushing and processing method

A cell fragmentation and microstructure technology, applied in biochemical equipment and methods, methods for stress-stimulated microbial growth, biochemical cleaning devices, etc. fragmentation and other problems, to achieve the effect of promoting a highly integrated microfluidic system, avoiding excessive fragmentation, and uniform cell fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The pipe diameter of the first cell suspension input tube unit of the present invention is 5 microns, and the tube diameter of the second cell suspension input tube unit is 100 microns. The purpose is to break up the cell suspension into particles with a particle size of 5 microns and hit them against the breaking plate. The pipe diameter of the first high-speed carrier gas input pipe unit is 50 microns, and the pipe diameter of the second carrier gas input pipe unit is 100 microns, in order to increase the output flow rate of nitrogen. Because of the small size of the structure, the structure can be processed and integrated into a microfluidic chip.

Embodiment 2

[0058] The pipe diameter of the first cell suspension input tube unit of the present invention is 5 microns, and the tube diameter of the second cell suspension input tube unit is 100 microns. The purpose is to break up the cell suspension into particles with a particle size of 5 microns and hit them against the breaking plate. The pipe diameter of the first high-speed carrier gas input pipe unit is 50 microns, and the pipe diameter of the second carrier gas input pipe unit is 100 microns, in order to increase the output flow rate of nitrogen. Add a filter device at the output end of the crushing chamber to filter out DNA or RNA in the cell residue, and then flow the output liquid into the PCR instrument for replication. This implementation case can simplify the experimental steps and save experimental operation time.

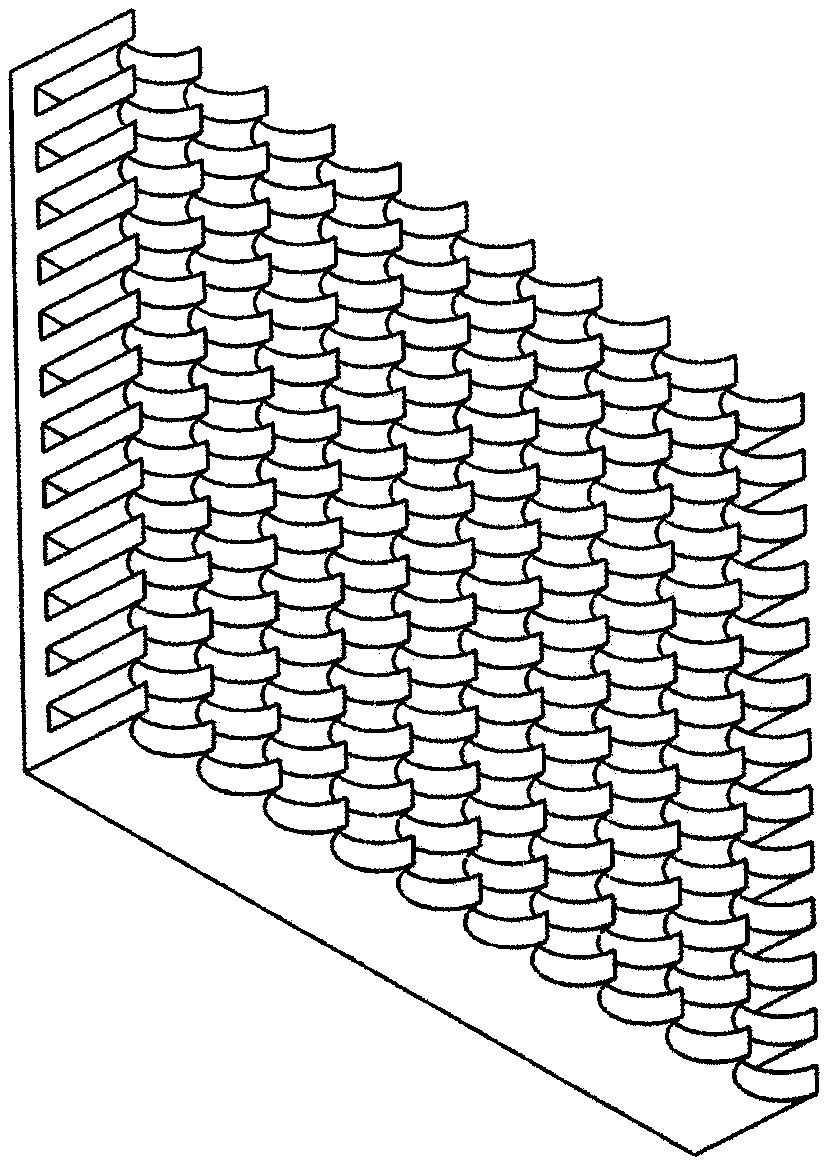

[0059] As a further preferred solution of the technical solution of the present invention, the piercing structure on the crushing plate is a cone array structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com