A kind of n-p heterogeneous porous spherical gas sensitive material and its preparation method

A gas-sensitive material, n-p technology, which is applied in material resistance, material analysis, material analysis by electromagnetic means, etc., can solve the problems of complex structure, slow response speed and high price, and achieve high sensitivity, low price and selectivity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The steps are:

[0011] 1. Add 4.85 g Ni(NO 3 ) 2 • 6 H 2 O was placed in a bubbling stirred tank, and cyclohexane, water, n-hexanol and sodium lauryl sulfate were added, stirred and fully dissolved in a water bath at 10°C; 2. From the bottom of the bubbling stirred tank, the rate into CO 2 Bubble for 30 min, then increase the pressure in the bubbling stirred tank to 0.05 MPa, stop feeding CO 2 ; 3. Add 2mol / L NaOH solution dropwise to pH = 11, and let it stand for 2 h; 4. Add 1.46g SnCl 4 ·5H 2 O and stirred at 60 °C to powder, and then put into a muffle furnace for calcination at 600 °C for 6 h to obtain n-p heterogeneous porous spherical gas-sensing materials.

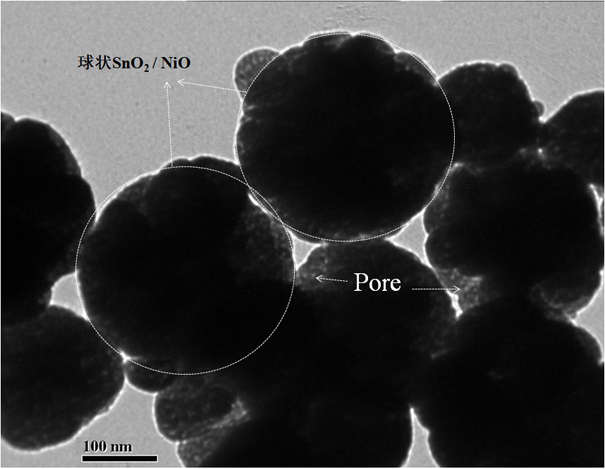

[0012] Carry out XRD and TEM characterization to the sample prepared in embodiment 1, detect SnO 2 phase and NiO phase, and found nano-SnO 2 Loaded on the structure of porous spherical NiO; the sensitivity of the sample prepared in Example 1 to 5 ppm NO at 300 °C is 13.4, and the recovery time is 13s;...

Embodiment 2

[0014] The steps are:

[0015] 1. Add 4.85 g Ni(NO 3 ) 2 • 6 H 2 O was placed in a bubbling stirred tank, and cyclohexane, water, n-hexanol and sodium lauryl sulfate were added, stirred and fully dissolved in a water bath at 5°C; 2. From the bottom of the bubbling stirred tank, the rate into CO 2 Bubble for 30 min, then increase the pressure in the bubbling stirred tank to 0.1 MPa, stop feeding CO 2 ; 3. Add 2mol / L NaOH solution dropwise to pH = 8, and let stand for 1 h; 4. Add 1.46 g SnCl 4 ·5H 2 O and stirred at 80 °C to powder, and then placed in a muffle furnace for calcination at 700 °C for 4 h to obtain n-p heterogeneous porous spherical gas-sensing materials.

[0016] Carry out XRD and TEM characterization to the sample prepared in embodiment 2, detect SnO 2 phase and NiO phase, and found nano-SnO 2 The structure supported on porous spherical NiO; the sensitivity of the sample prepared in Example 2 to 5 ppm NO at 300 °C is 11.8, and the recovery time is 12s; the...

Embodiment 3

[0018] The steps are:

[0019] 1. Add 4.85 g Ni(NO 3 ) 2 • 6 H 2 O was placed in a bubbling stirred tank, and cyclohexane, water, n-hexanol and sodium lauryl sulfate were added, stirred and fully dissolved in a water bath at 20°C; rate into CO 2 Bubble for 30min, then increase the pressure in the bubbling stirred tank to 0.08 MPa, stop feeding CO 2 ; 3. Add 2mol / L NaOH solution dropwise to pH = 10, and let stand for 1.5 h; 4. Add 0.73g SnCl 4 ·5H 2 O and stirred at 70 °C to powder, and then placed in a muffle furnace for calcination at 400 °C for 8 h to obtain n-p heterogeneous porous spherical gas-sensing materials.

[0020] Carry out XRD and TEM characterization to the sample prepared in embodiment 3, detect SnO 2 phase and NiO phase, and found nano-SnO 2 The structure supported on porous spherical NiO; the sensitivity of the sample prepared in Example 3 to 5 ppm NO at 300 °C is 12.8, and the recovery time is 12s; for 5 ppm NO 2 The sensitivity is 16.1 and the recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com