Adhesive bandage containing nano-silver particles and preparation method of adhesive bandage

A technology of nano-silver particles and band-aids, applied in the field of medicine, can solve the problems of low production efficiency, needle blockage, and inability to evenly distribute nano-silver ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of Band-aid containing nano-silver particles

[0037] 1. Preparation of disinfection layer

[0038] Preparation of electrospinning liquid: after dissolving polyvinyl butyral in ethanol, add silver nitrate, stir to dissolve, and prepare electrostatic spinning liquid; the concentration of silver nitrate is 0.5wt%, the concentration of PVB is 7.375wt%, magnetic stirring for 15-18h , so that it completely dissolves to a transparent state,

[0039] Electrospinning: electrospinning the electrospinning solution to obtain silver nitrate textile fibers; the ambient temperature of the electrospinning process is controlled at 22-28°C and the relative humidity is 40%-60%. The electrospinning process parameters are: collection distance (12±1) cm, voltage (22±2) kV, flow rate 1.5 mL / h, single needle, and spinning for 10 hours.

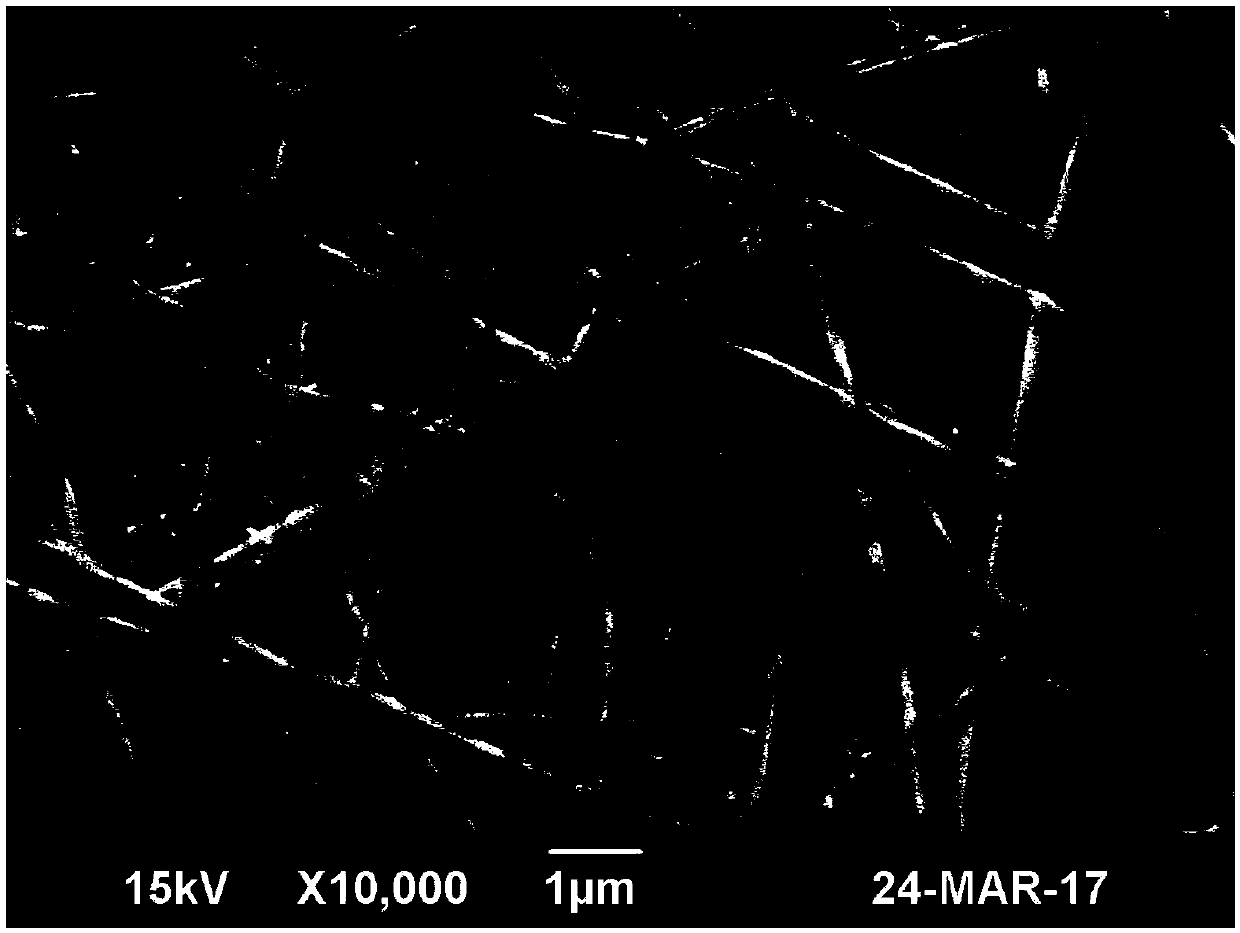

[0040] Decomposition of silver nitrate: The silver nitrate textile fiber is irradiated with ultraviolet light, and the silver nitrate i...

Embodiment 2

[0051] Embodiment 2 A kind of Band-aid containing nano-silver particles

[0052] 1. Preparation of disinfection layer

[0053] Preparation of electrospinning liquid: after dissolving polyvinyl butyral in ethanol, adding silver nitrate, stirring and dissolving, preparing electrospinning liquid; wherein the concentration of silver nitrate is 1wt%, the concentration of PVB is 7.375wt%, magnetically stirred for 15-18h, make it completely dissolved to become transparent,

[0054] Electrospinning: electrospinning the electrospinning solution to obtain silver nitrate textile fibers; the ambient temperature of the electrospinning process is controlled at 22-28°C and the relative humidity is 40%-60%. The electrospinning process parameters are: collection distance (12±1) cm, voltage (22±2) kV, flow rate 1.5 mL / h, single needle, and spinning for 10 hours.

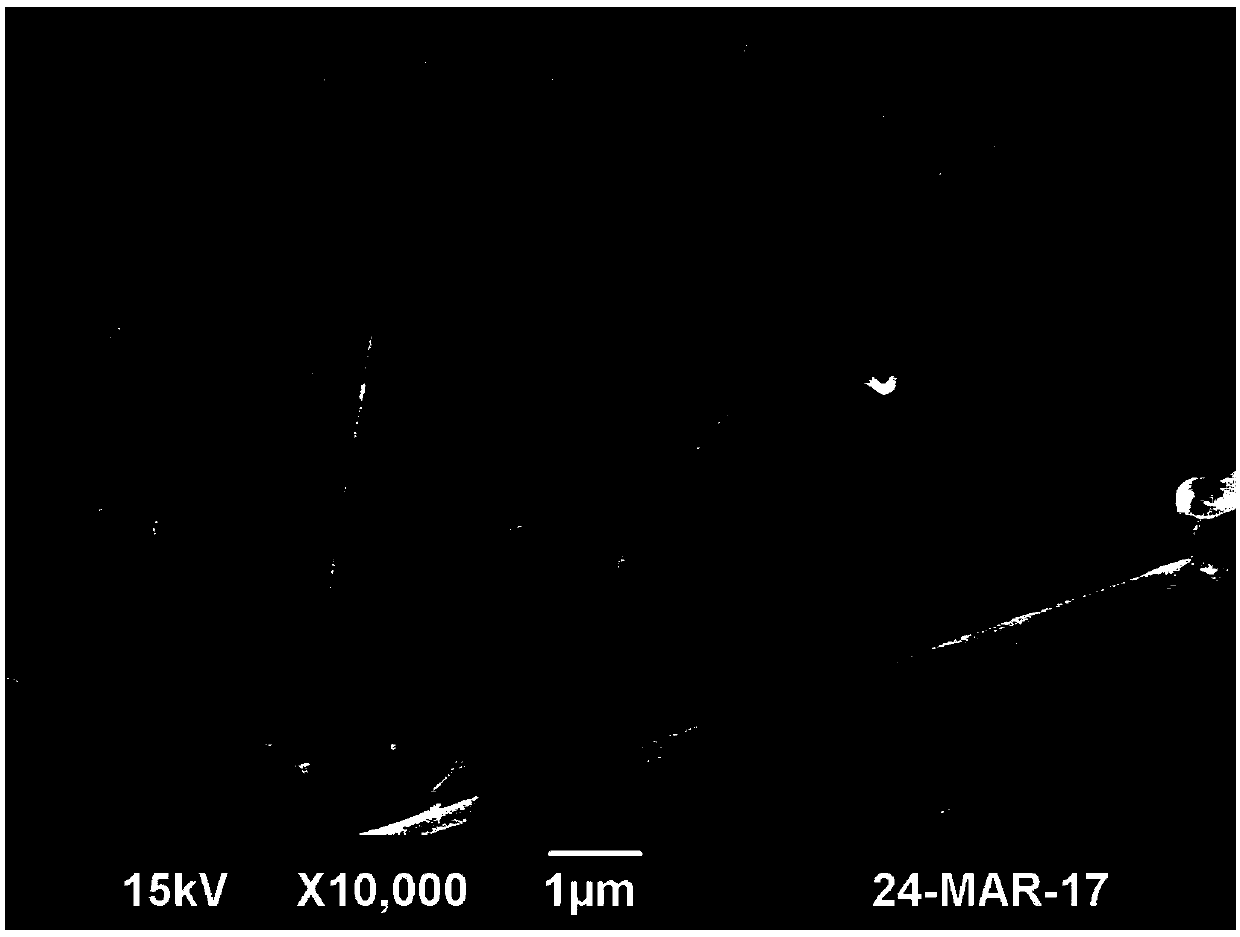

[0055] Decomposition of silver nitrate: The silver nitrate textile fiber is irradiated with ultraviolet light, and the silver nitr...

Embodiment 3

[0062] Embodiment 3 A kind of Band-Aid Containing Nano Silver Particles

[0063] 1. Preparation of disinfection layer

[0064] Preparation of electrospinning liquid: after dissolving polyvinyl butyral in ethanol, adding silver nitrate, stirring and dissolving, preparing electrospinning liquid; wherein the concentration of silver nitrate is 2wt%, the concentration of PVB is 7.375wt%, magnetically stirred for 15-18h, make it completely dissolved to become transparent,

[0065] Electrospinning: electrospinning the electrospinning solution to obtain silver nitrate textile fibers; the ambient temperature of the electrospinning process is controlled at 22-28°C and the relative humidity is 40%-60%. The electrospinning process parameters are: collection distance (12±1) cm, voltage (22±2) kV, flow rate 1.5 mL / h, single needle, and spinning for 10 hours.

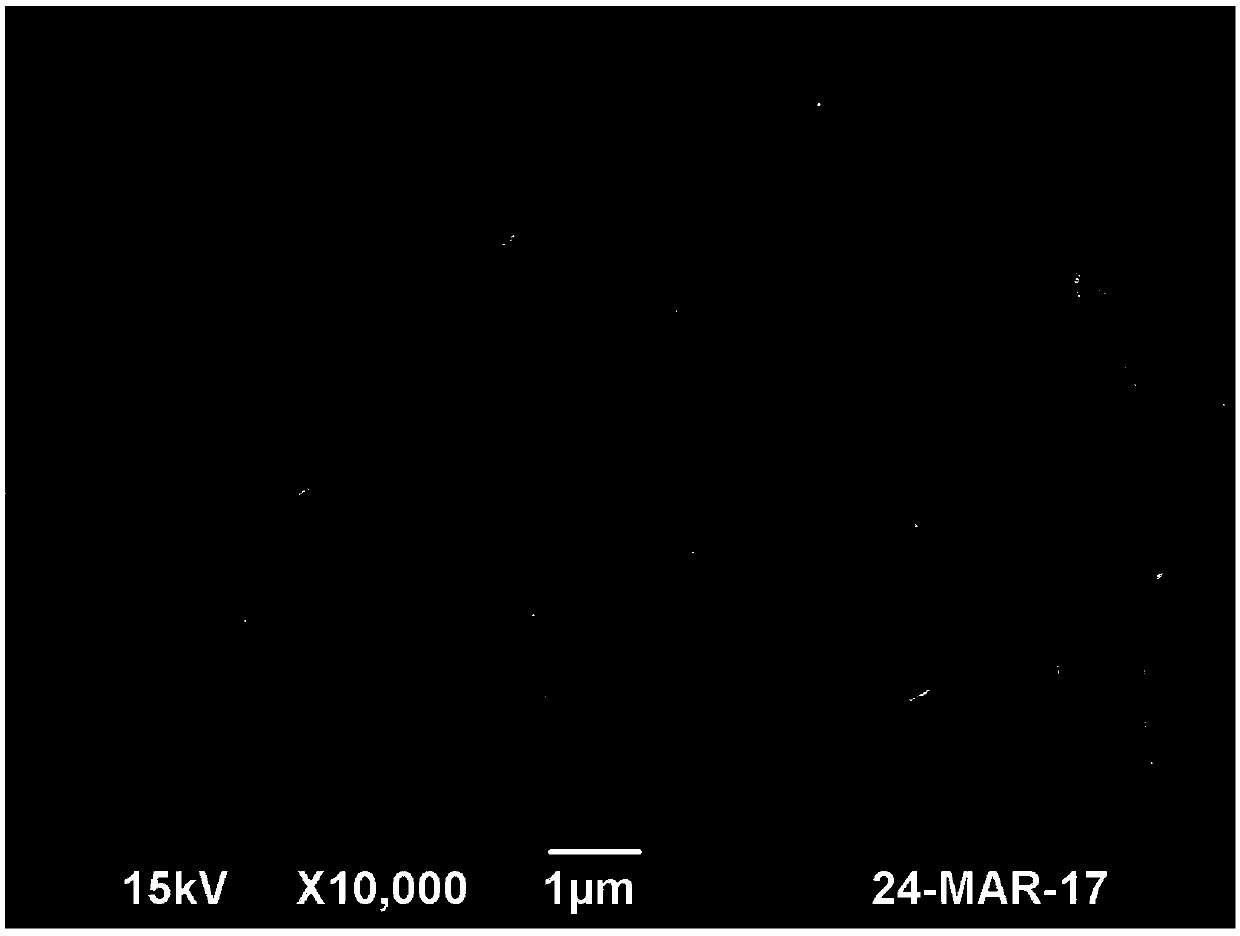

[0066] Decomposition of silver nitrate: The silver nitrate textile fiber is irradiated with ultraviolet light, and the silver nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com