Phosphine-based modified metal catalyst and method for catalyzing ethylene oligomerization to produce 1-hexene-1-laurylene

A metal catalyst and ethylene oligomerization technology, which is applied in the direction of catalyst, bulk chemical production, carbon compound catalyst, etc., can solve the problem of single structure and few, and achieve high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

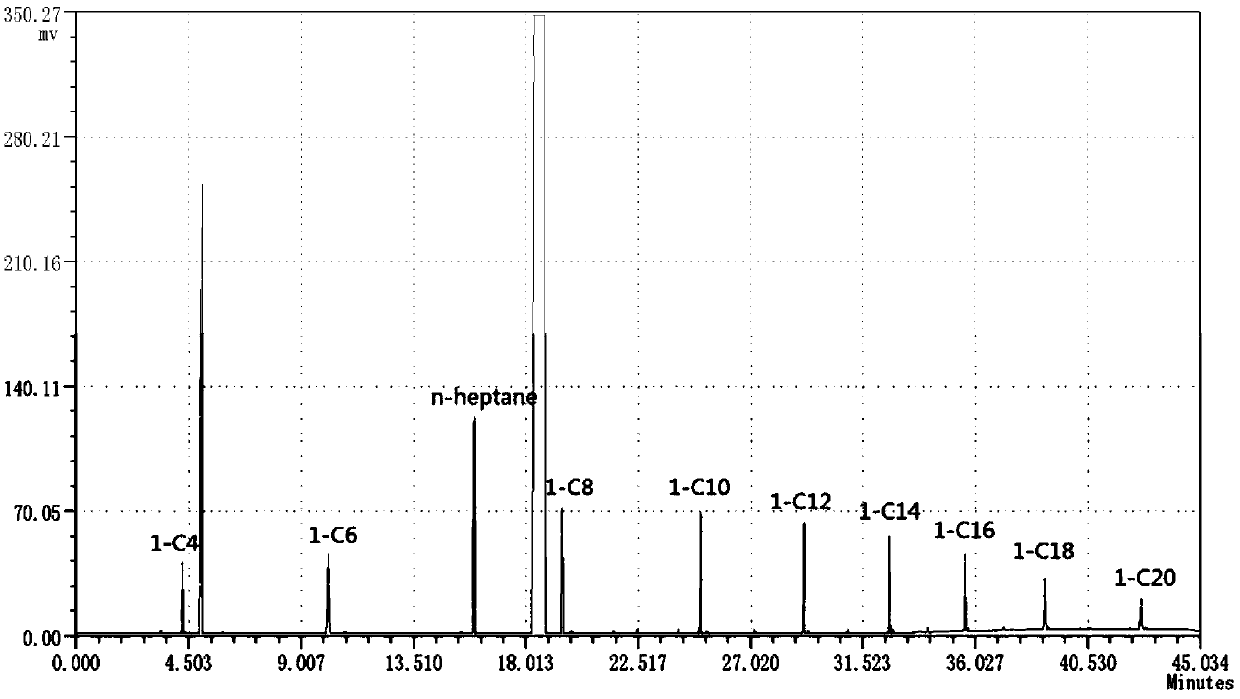

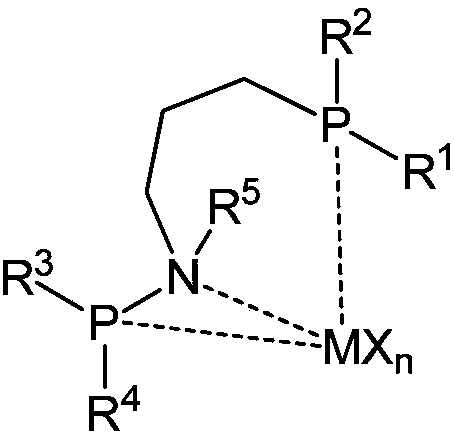

[0030] The method for producing 1-hexene to 1-dodecene by ethylene oligomerization is as follows, and the catalyst shown below is used to catalyze ethylene oligomerization.

[0031]

[0032] A 1 mmol / L catalyst toluene solution was freshly prepared in the glove box, and 10 mL of the catalyst solution was measured for use. Install the reaction kettle, preheat to 100°C, vacuum dry, cool to room temperature, replace with ethylene atmosphere, add 10mL catalyst toluene solution, 1mL methylaluminoxane toluene solution with a concentration of 1.5mol / L, 50mL toluene, Rapidly heated to 60°C, while raising the ethylene pressure to 4MPa, stirring at 500rpm, and maintaining for 60min. Rapidly cool the reaction system to 0°C, release the pressure, add 100mL of absolute ethanol and 5mL of 10% hydrochloric acid to quench, oscillate, stand still, add 5g of n-heptane internal standard, and use the organic phase liquid for gas chromatography analysis. The catalyst activity calculated by the...

Embodiment 2

[0034] The reaction temperature in Example 1 was adjusted from 60°C to 50°C, and other operating conditions were unchanged, and the catalyst activity calculated by the internal standard method was 4.6×10 6 g / mol Cr h, the product composition is recorded in Table 1.

Embodiment 3

[0036] The reaction temperature in Example 1 was adjusted from 60°C to 40°C, and other operating conditions were unchanged, and the catalyst activity calculated by the internal standard method was 6.5×10 6 g / mol Cr h, the product composition is recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com