A kind of method for preparing terephthalonitrile by polyethylene terephthalate

A technology of terephthalonitrile and solid acid catalyst, which is applied to the preparation of carboxylic acid nitrile, chemical instruments and methods, and the preparation of organic compounds, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

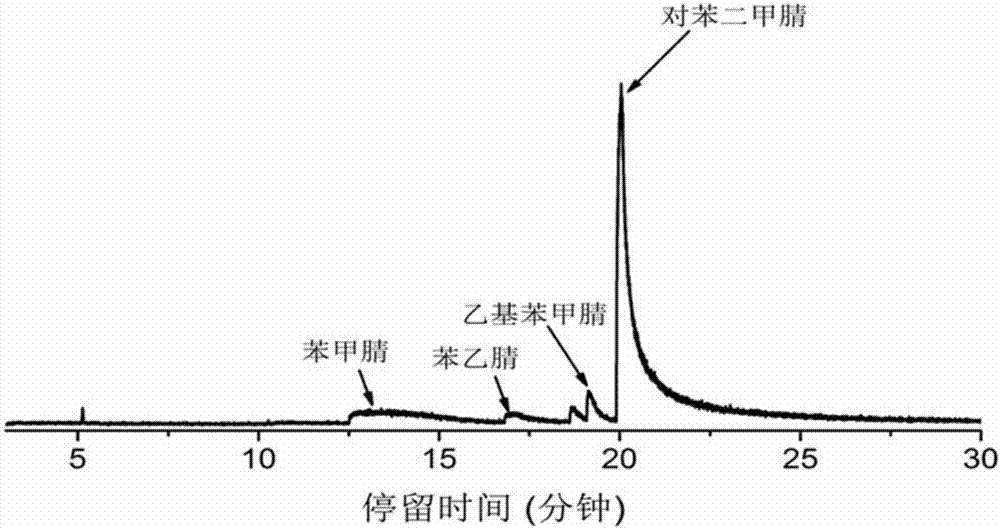

[0030] In this example, a quartz tubular reactor with a diameter of 10 mm and a length of 250 mm was used. In the reactor, the catalyst was supported by quartz wool. Install the quartz reactor in a temperature-controlled furnace. Reactor temperature was monitored by thermocouples inserted into the surface of the temperature-controlled furnace packed bed. During operation, use NH 3 , NH 3 / N 2 or NH 3 / He mixed gas is used as the carrier gas, and its flow rate is controlled by a gas flow meter. The powdery raw materials flow together with the carrier gas flow from the opening of the quartz tube to the pyrolysis interface. The reaction temperature is 200-1000°C, and the carrier gas flow rate is 5-200mL / min. Liquid products flow from the reactor to the condenser and gaseous products are collected in gas sampling bags. Liquid and gaseous products were analyzed using a gas chromatograph.

Embodiment 2

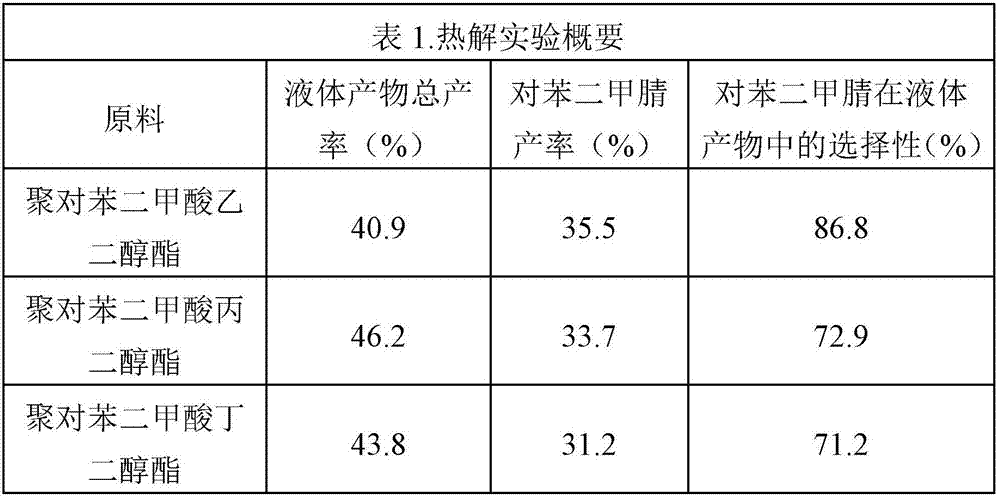

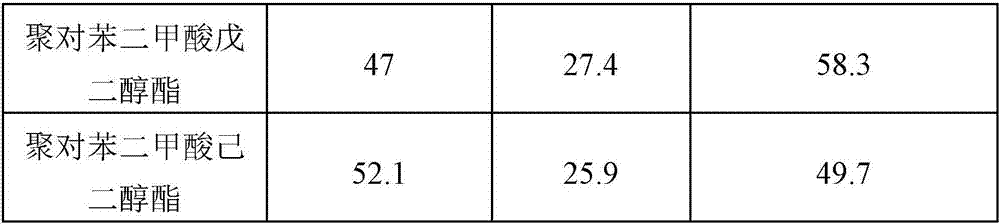

[0034] In this example, polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, polypentylene terephthalate, polyterephthalate Preparation of terephthalonitrile by catalytic pyrolysis of different raw materials such as hexanediol ester.

[0035]

[0036]

[0037] Reaction conditions: the reaction temperature is 600°C; the catalyst is P 2 o 5 / Al 2 o 3 ; Ammonia gas flow rate = 60mL / min.

Embodiment 3

[0039] In this embodiment, the influence of different reaction temperatures on the yield and selectivity of terephthalonitrile was tested.

[0040]

[0041] Reaction conditions: the raw material is polyethylene terephthalate; the catalyst is P 2 o 5 / Al 2 o 3 ; Ammonia flow = 60mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com