Retarded cement mixture and preparation process thereof

A technology of mixture and cement clinker, which is applied in the field of cement production, can solve the problems that concrete is not easy to set quickly, the retarding effect is not good, and the effect of retarding ingredients is not good, so as to achieve good synergistic effect and improve the retarding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: A kind of slow-setting cement mixture, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0051] Step 1, put cement clinker, fly ash, mineral powder and fluorine gypsum of corresponding parts by weight into the mixing tank for mixing, the stirring speed is 1100rpm, and the stirring time is 40min to obtain the basic mixed material;

[0052] Step 2, mixing and stirring the airgel, mixed retarder and polyvinyl alcohol in corresponding parts by weight, the stirring speed is 400rpm, and the stirring time is 30min, to obtain the combined masterbatch;

[0053] Step 3, mixing and stirring the above-mentioned basic mixture and combined masterbatch evenly, the stirring speed is 800rpm, and the stirring time is 60min, to obtain cement coarse material;

[0054] Step 4, the above-mentioned coarse cement material is transported into a roller press through a conveyor belt, and crushed under the actio...

Embodiment 2-8

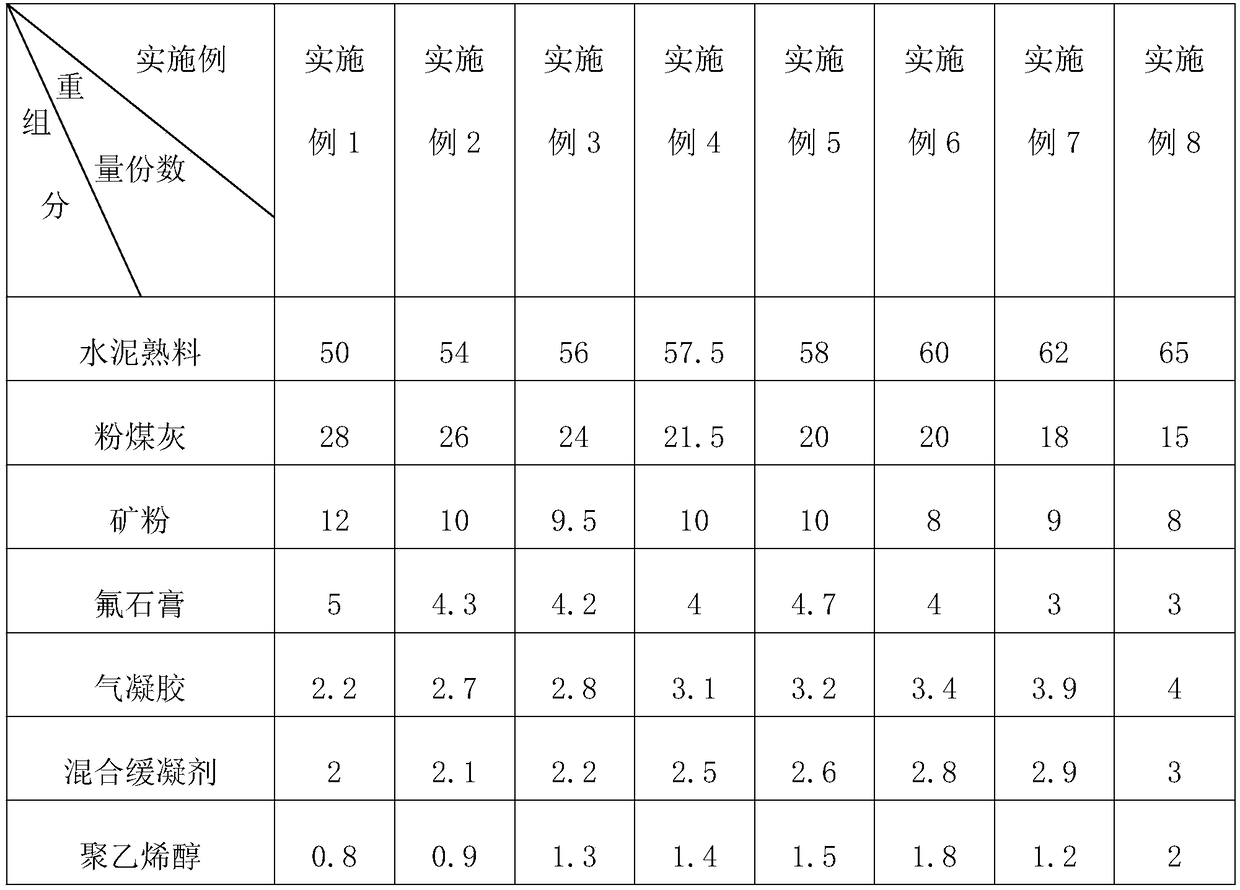

[0059] Embodiment 2-8: A slow-setting cement mixture. The difference from Embodiment 1 is that each component and its corresponding weight parts are shown in Table 1.

[0060] Each component and parts by weight thereof in table 1 embodiment 1-8

[0061]

Embodiment 9

[0062] Embodiment 9: A retarded cement mixture. The difference from Embodiment 1 is that the mixed retarder is obtained by mixing methyl phosphate and sodium tripolyphosphate in a ratio of 1:1 in parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com