Water-based paint for outdoor metal furniture and preparation method of paint

A water-based and metal-based technology, applied in coatings, etc., can solve the problems of slow development of water-based coatings and difficulty in meeting the high weather resistance requirements of coatings, and achieve the effects of improving film-forming efficiency, excellent weather resistance, and promoting improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

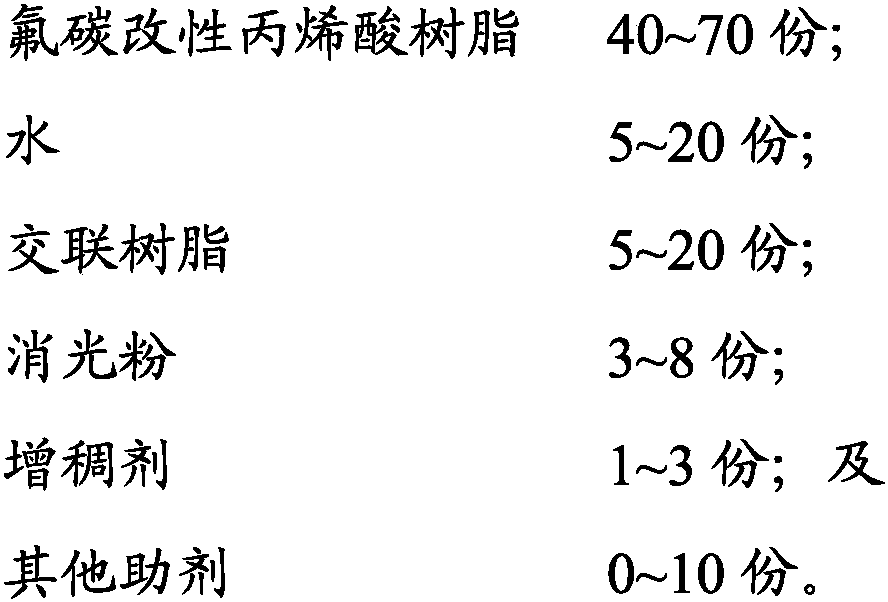

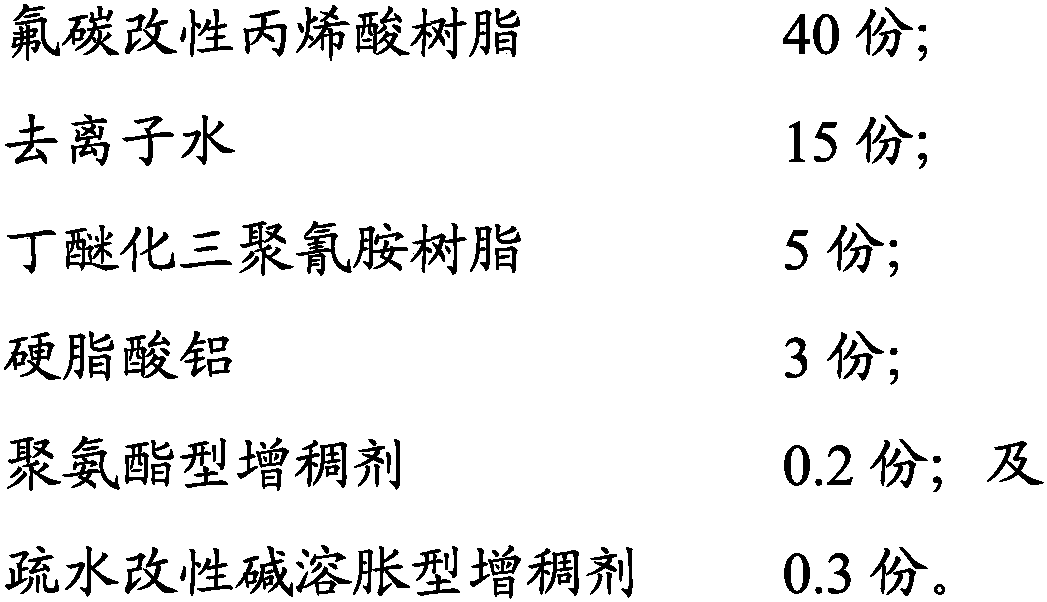

[0026] The water-based coating for outdoor metal furniture of the present embodiment, in parts by weight, includes:

[0027]

[0028] The method for preparing the water-based paint for outdoor metal furniture by using the above-mentioned raw materials includes:

[0029] 1) Add 40 parts of fluorocarbon modified acrylic resin, 3 parts of aluminum stearate and 5 parts of deionized water into the reaction vessel, stir evenly, the stirring speed is 600rpm, and the time is 30min, to obtain the mixture A;

[0030] 2) Add 5 parts of butylated melamine resin to the mixture A, stir evenly, the stirring speed is 600rpm, and the time is 30min, and the mixture B is obtained;

[0031] 3) Add 0.2 parts of polyurethane thickener, 0.3 parts of hydrophobically modified alkali-swellable thickener and 10 parts of deionized water to mixture B, and stir evenly at a stirring rate of 300 rpm for 15 minutes to obtain outdoor metal furniture Water-based paint.

Embodiment 2

[0033] The water-based coating for outdoor metal furniture of the present embodiment, in parts by weight, includes:

[0034]

[0035]

[0036] The method for preparing the water-based paint for outdoor metal furniture by using the above-mentioned raw materials includes:

[0037] 1) Add 60 parts of fluorocarbon modified acrylic resin, 5 parts of silicon dioxide, 0.2 parts of mineral oil defoamer, 0.5 parts of sodium salt dispersant and 9 parts of deionized water into the reaction vessel, stir well, and the stirring speed is 600rpm , the time is 30min, to obtain the mixture A;

[0038] 2) Add 0.3 parts of AMP-95, 0.2 parts of silicone oil, 0.4 parts of benzotriazoles, 0.2 parts of organic acid soap, 2 parts of propylene glycol, 4 parts of alcohol ester twelve, 5 parts of butylated melamine resin to mixture A 1 part and 0.2 part of mineral oil defoamer, stir evenly, the stirring rate is 600rpm, the time is 30min, to obtain the mixture B;

[0039]3) Add 0.2 parts of polyur...

Embodiment 3

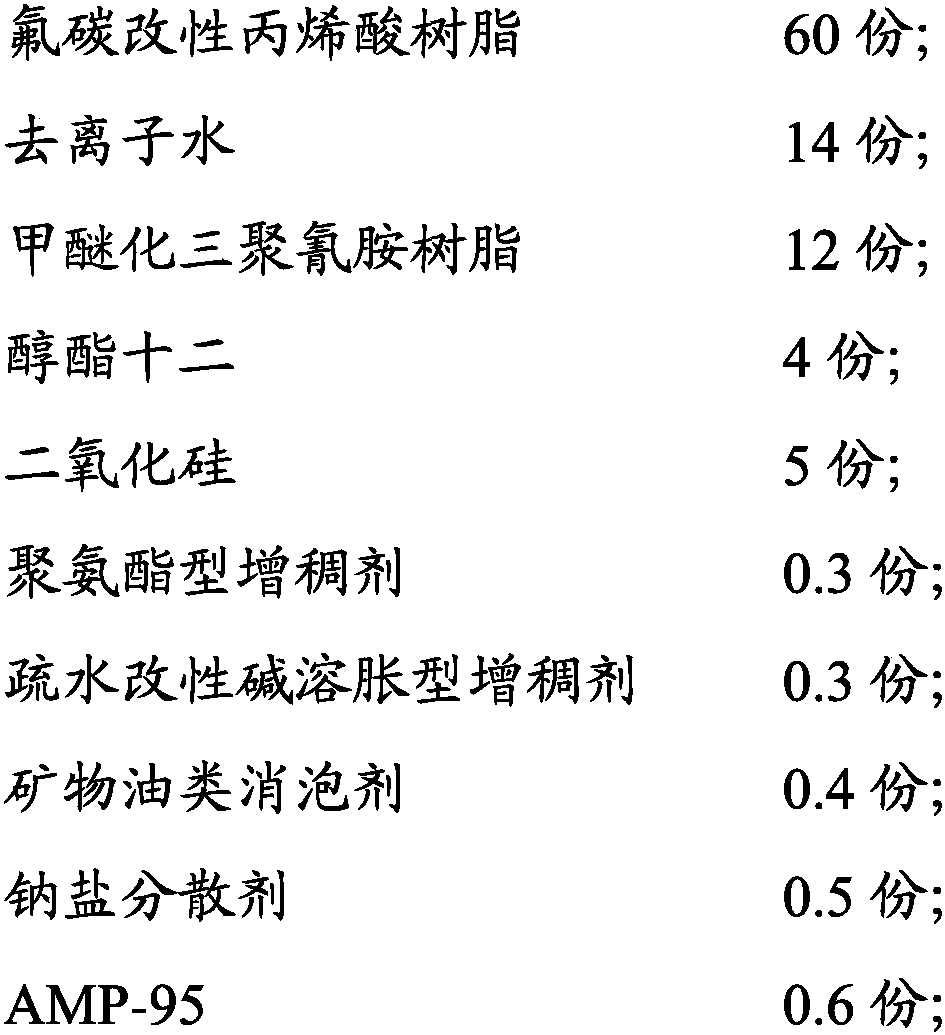

[0041] The water-based coating for outdoor metal furniture of the present embodiment, in parts by weight, includes:

[0042]

[0043] The preparation method of the water-based coating for outdoor metal furniture in this example is the same as that in Example 2, and the components that do not appear in the preparation method can be reduced accordingly, and no detailed description is given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com