Method for preparing vermiculite fluorescent thin film composite material

A thin-film composite material and vermiculite technology, which is applied in the direction of luminescent materials, chemical instruments and methods, coatings, etc., can solve the problems of short life of organic cationic phosphors and insufficient development and utilization of vermiculite, and achieve microscopic controllability and realization quick and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a vermiculite fluorescent film composite material, which combines vermiculite and an organic cationic phosphor to form a composite material, specifically adopts the following technical scheme, including the following steps:

[0035] (1) Add water to the vermiculite with 20Hz-1000MHz ultrasonic wave and heat it to 40-350°C to peel off and pulverize, then use 8000-230000rpm to centrifuge and wash and separate the vermiculite, and the precipitate after centrifugation is ultrasonically dispersed into deionized water to obtain 1-1000nm nano flake vermiculite solution, and the concentration of nano flake vermiculite solution is 0.001-1g / ml;

[0036] (2) Ultrasonic dispersion and dissolution of pyrrored or rhodamine B6G or cadmium sulfide quantum dots or cadmium selenide quantum dots or cadmium telluride quantum dots to obtain a fluorescent molecular solution;

[0037] (3) Treat transparent quartz glass or PET film with radio frequency power 0-5000W, rad...

Embodiment 1

[0042]A preparation method of vermiculite fluorescent film composite material, comprising the following steps:

[0043] (1) Add water to the vermiculite with 20Hz ultrasound and heat it to 40°C to peel off and pulverize the mixture. The centrifuge separates the mixture at a speed of 10,000rpm, and the precipitated solid after centrifugation is dispersed into pure water to obtain a vermiculite nanosheet solution;

[0044] (2) ultrasonically dissolving rhodamine B6G to obtain a fluorescent molecular solution of rhodamine B6G;

[0045] (3) Treat the transparent PET film with plasma with a radio frequency of 5 MHz and ultraviolet rays with an intensity of 3000uW / cm to obtain a hydrophilic PET film;

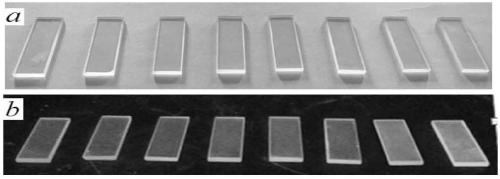

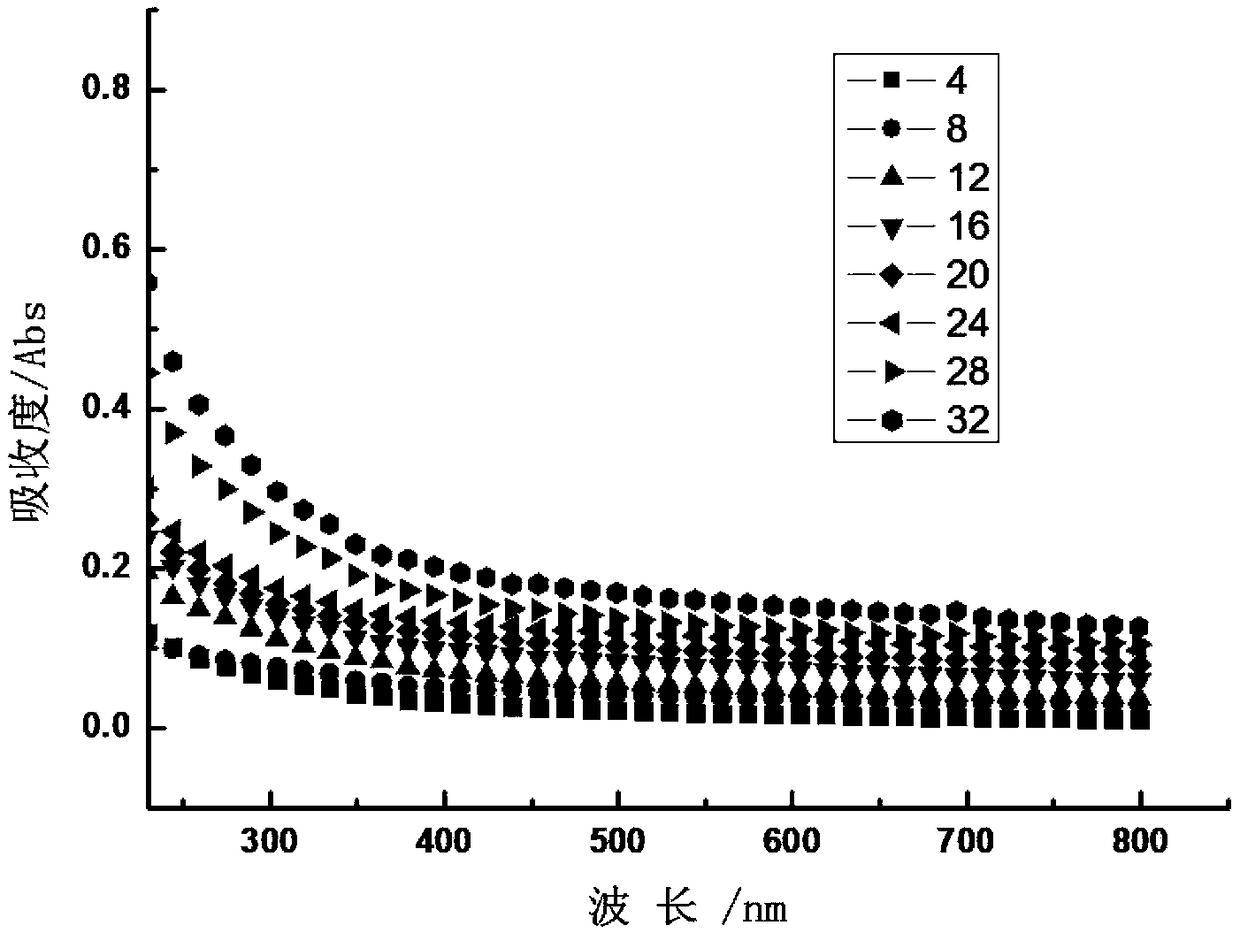

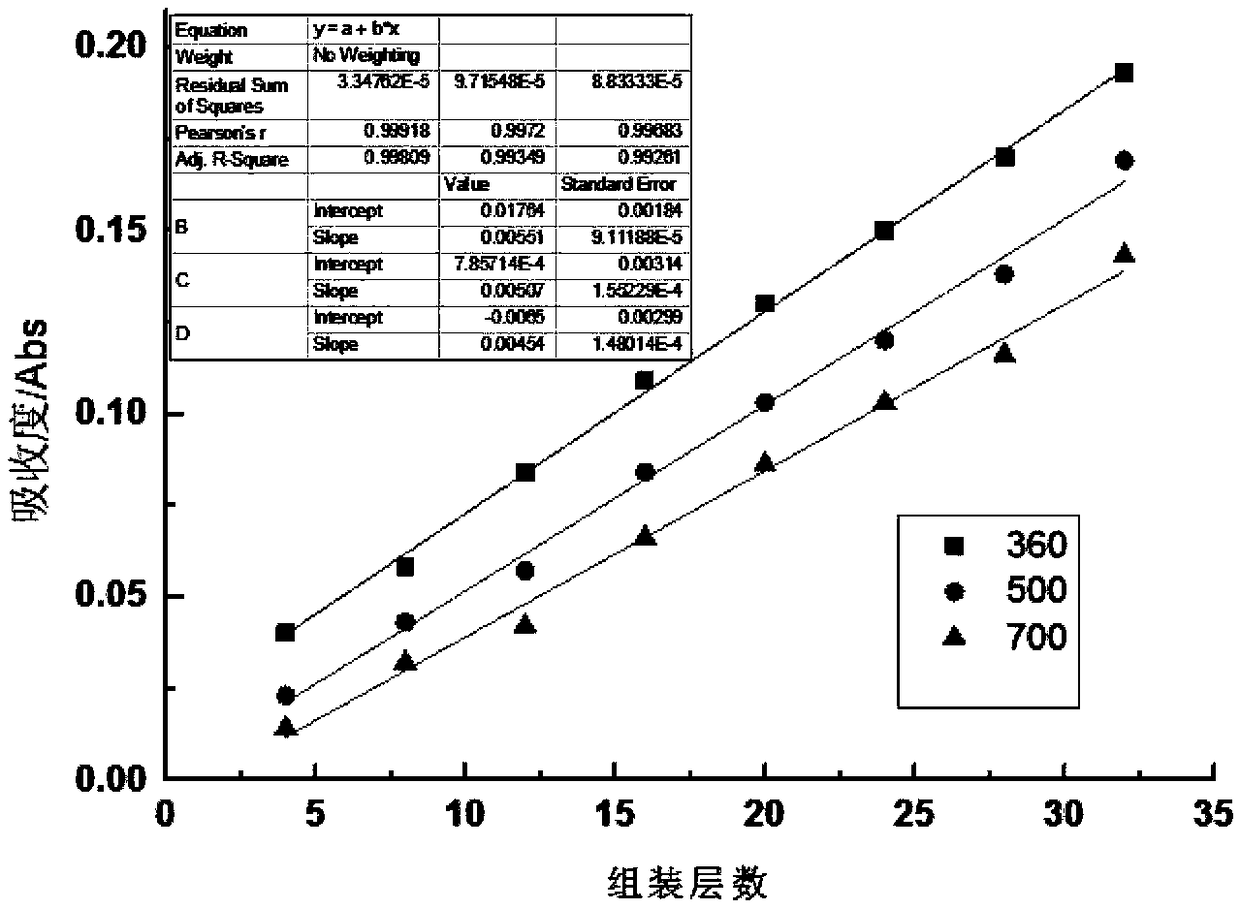

[0046] (4) Soak the PET film treated in step (3) in rhodamine B6G fluorescent molecule solution for 10 minutes, wash with water for 3 minutes, then soak in vermiculite colloid solution for 10 minutes, wash with water for 3 minutes, and then The rhodamine B6G fluorescent molecule solu...

Embodiment 2

[0048] A preparation method of vermiculite fluorescent film composite material, comprising the following steps:

[0049] (1) Add water to the vermiculite with 200Hz ultrasonic wave and heat it to 100°C to peel and pulverize it. The centrifuge separates the mixture at a speed of 15,000rpm, and the precipitated solid after centrifugation is dispersed into pure water to obtain a vermiculite nanosheet solution;

[0050] (2) ultrasonically dissolving the cadmium sulfide quantum dots modified by hexadecyl bromide collidine to obtain a fluorescent molecular solution of cadmium sulfide quantum dots;

[0051] (3) Treat the transparent quartz glass with a plasma with a radio frequency power of 100W and a radio frequency of 200MHz to obtain hydrophilic quartz glass;

[0052] (4) Soak the quartz glass treated in step (3) in the cadmium sulfide quantum dot fluorescent molecule solution for 10 minutes, wash with water for 5 minutes, then soak in vermiculite colloid solution for 10 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com