A method for synergistic extraction and separation of manganese, calcium and magnesium

An extraction and extraction agent technology, applied in the field of chemical extraction, can solve the problems of incomplete separation of calcium and magnesium, high cost, complicated process, etc., and achieve the effect of good impurity removal effect, low cost and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for synergistically extracting and separating manganese, calcium and magnesium of the present invention, comprising:

[0034] Aqueous phase material solution: lean pyrolusite leaching solution, containing 11.0g / L Mn 2+ , 4.8g / L Mg 2+ , 0.35g / L Ca 2+ , The pH of the feed solution is 3.12.

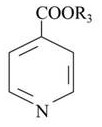

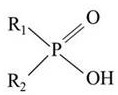

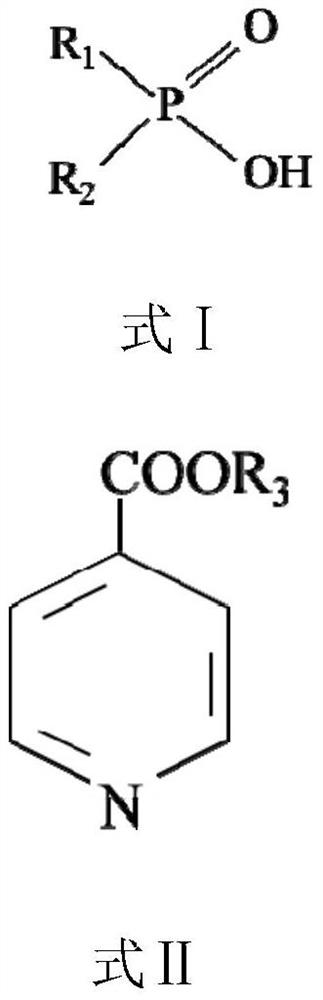

[0035] Organic phase: Prepare three organic phases with different compositions numbered 1, 2, and 3. The diluent in the organic phase is sulfonated kerosene, and the organic phase No. 1 is sulfonated kerosene with 0.25mol / L phosphoric acid extractant P204 Solution, No. 2 organic phase is the sulfonated kerosene solution of 1mol / L pyridine decanoate, No. 3 is the sulfonated kerosene solution of P204+1mol / L pyridine decanoate that organic phase is 0.25mol / L, utilizes ammonia water to above-mentioned Three kinds of organic phases were subjected to saponification treatment (saponification rate was 60%).

[0036] Extraction and separation: The saponification-treated organic ph...

Embodiment 2

[0041] A method for synergistically extracting and separating manganese, calcium and magnesium of the present invention, comprising:

[0042] The aqueous phase material liquid is the liquid after reducing pyrolusite with waste iron scraps and removing impurities, containing 22.01g / L Mn 2+ , 4.12g / L Mg 2+ , 0.10g / L Ca 2+ , the feed liquid pH is 4, the organic phase is: 0.3mol / L phosphoric acid extractant P507+0.7mol / L aviation kerosene solution of pyridine caprylate, utilize ammonia water to carry out saponification treatment (saponification rate is 60%).

[0043] A separatory funnel was used for single-stage extraction, the extraction ratio was 3 / 1, the extraction mixing time was 10 min, and the temperature was 35°C. The experimental results are shown in Table 2.

[0044] Table 2 Extraction Results

[0045]

[0046] It can be seen from Table 2 that during the extraction process, the single-stage extraction rate of manganese can reach 94.7%, magnesium and calcium are basi...

Embodiment 3

[0048] The aqueous phase feed solution is the same as in Example 2; the organic phase is the Escaid 110 solution of 0.3mol / L phosphoric acid extractant 5709+1mol / L pyridine nonanoate, which is saponified with ammonia water (saponification rate is 60%).

[0049] A separatory funnel was used for single-stage extraction, the extraction ratio was 6 / 1, the extraction mixing time was 10 min, and the temperature was 5°C. The experimental results are shown in Table 3.

[0050] Table 3 Extraction Results

[0051]

[0052] It can be seen from Table 3 that during the extraction process, the single-stage extraction rate of manganese can reach 96.4%, and magnesium and calcium are basically not extracted. The separation coefficients of Mn / Mg and Mn / Ca are respectively above 630 and 220, and the separation effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com