Oxygen-bearing hydrogenated yttrium photo-thermal discoloration multilayer thin-film material

A multi-layer film, yttrium hydride technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems of poor weather resistance, low solar energy regulation rate, low decolorization rate, etc., and achieve light transmittance. High, rapid decolorization by heat, rapid photochromic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

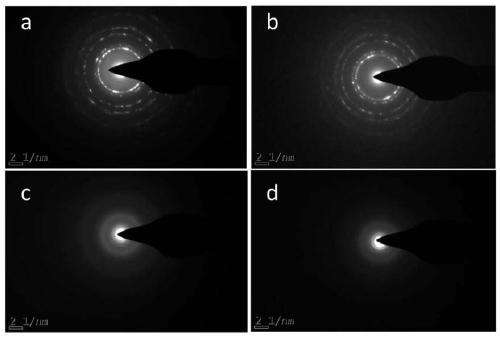

[0046] Preparation of Dimming Layer Containing Yttrium Oxyhydride. Wherein, the target material of the dimming layer containing yttrium hydride is metal yttrium or yttrium hydride. Its preparation method can be prepared by adopting but not limited to DC magnetron sputtering technology or AC magnetron sputtering technology. For example, using metal yttrium as the target material, the dimmer layer containing yttrium oxyhydride is prepared on the surface of the substrate by DC magnetron sputtering technology. Alternatively, using yttrium hydride as a target material, an AC magnetron sputtering technique is used to prepare an oxygen-containing yttrium hydride dimming layer on the surface of the substrate.

[0047] In one embodiment of the present invention, using metal yttrium as the target material, the parameters for preparing the dimmer layer containing yttrium oxyhydride by DC magnetron sputtering technology include: background vacuum-5 Pa, mixed atmosphere of argon and hydro...

Embodiment 1

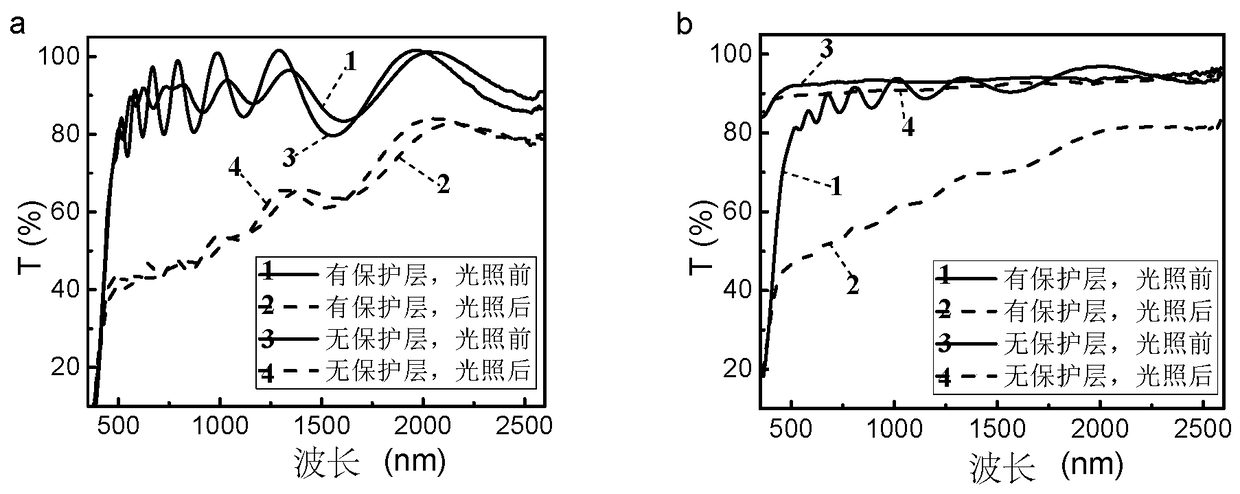

[0058] Example 1 Preparation of photothermochromic multilayer film containing yttrium oxyhydride

[0059] 1) Cleaning of the substrate

[0060] Put the glass piece in a beaker, and ultrasonically treat it in 0.5mol / L NaOH solution, deionized water, ethanol, and deionized water for 10 minutes respectively, and then use pH test paper to confirm that the final washing solution is neutral. Put the glass piece into a beaker, add an appropriate amount of ethanol, and sonicate for 10 minutes;

[0061] 2) Preparation of photothermochromic multilayer film:

[0062] Method 1: The magnetron sputtering system adopts the DC current magnetron sputtering method. The vacuum system is composed of a molecular pump and a mechanical pump. The background vacuum degree of the vacuum chamber reaches 10 -5 Magnitude. The target components are 2 inches of pure yttrium metal, 2 inches of pure tungsten metal and 2 inches of pure aluminum metal. After the background vacuum reaches the requirement, pu...

Embodiment 2

[0080] 1) cleaning the glass substrate;

[0081] 2) Preparation of photothermochromic multilayer film:

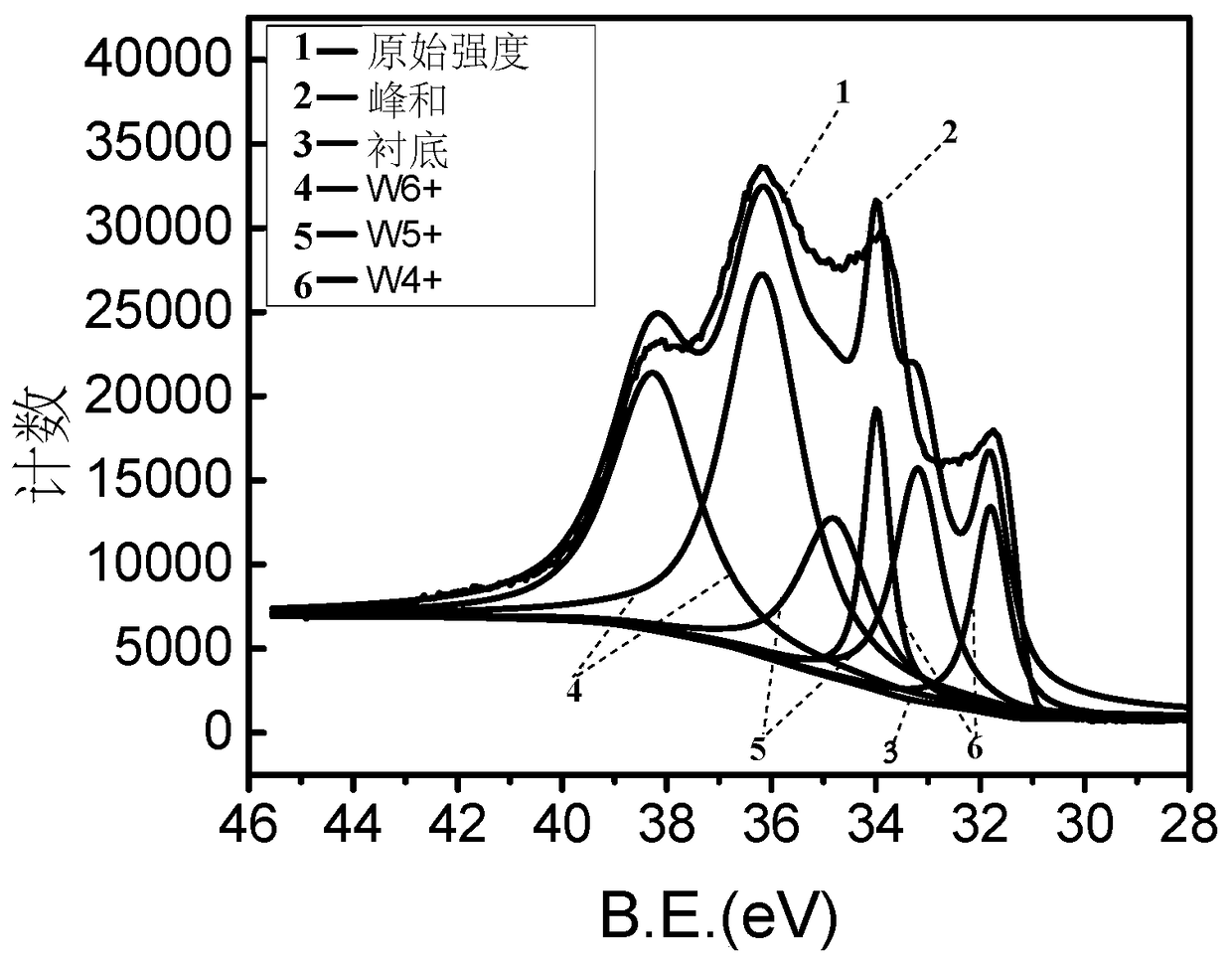

[0082] Method 1: The magnetron sputtering system adopts the DC current magnetron sputtering method. The vacuum system is composed of a molecular pump and a mechanical pump. The background vacuum degree of the vacuum chamber reaches 10 -5 Magnitude. The target components were 2 inches of yttrium hydride metal and 2 inches of pure tungsten metal. After the background vacuum reaches the requirement, put the cleaned substrate into the deposition chamber, and then fill the vacuum chamber with high-purity Ar gas and H 2 Gas, volume ratio (3:2), flow rate (35sccm:12sccm). Control the substrate rotation speed to 5r / min. Wait until the pressure of the deposition chamber is stabilized at 0.4-2Pa;

[0083] a) The Y target material is deposited by sputtering with a DC power supply, the sputtering parameters are: W(Y)=60W, t(Y)=3000s, and the dimming layer containing yttrium oxyhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com