Preparation method of crisp fruit and vegetable chips without adding color retention agent

A technology for fruit and vegetable chips and a color-preserving agent, which is applied in the direction of protecting fruits/vegetables with a protective layer, keeping fruits and vegetables fresh, and preserving fruits/vegetables by dehydration, etc., can solve product quality decline, shortened shelf life, browning, etc. problem, to prevent discoloration, reduce enzymatic browning, and reduce the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

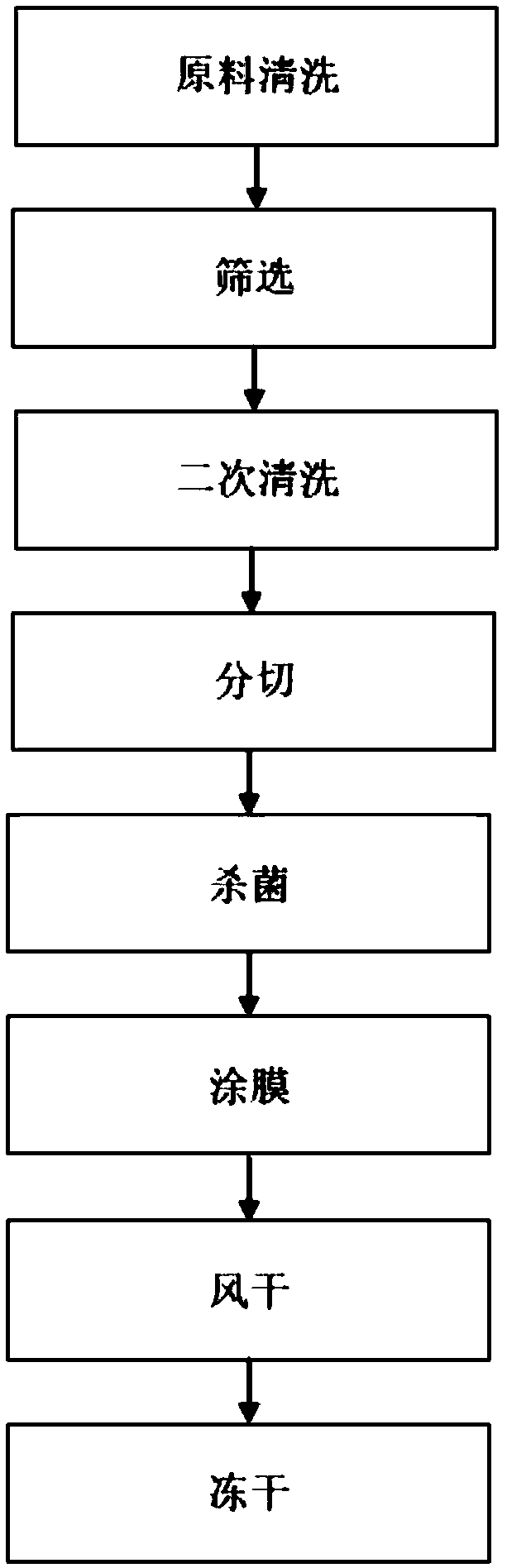

[0030] combine figure 1 As shown, a method for preparing dried apples without the addition of a color-protecting agent mainly includes the following steps: raw material cleaning, screening, secondary cleaning, cutting, sterilization, film coating, air drying and freeze drying;

[0031] (1) Raw material cleaning: Use a high-pressure cleaner to clean the raw material to remove sediment and foreign matter on the surface of the raw material;

[0032] (2) Screening: remove the inedible parts of the raw materials, classify the raw materials, select qualified raw materials, and then process them into certain specifications. The screening process is carried out on the conveyor belt, and the low-temperature water is continuously sprayed during the screening process;

[0033] (3) Secondary cleaning: the screened raw materials are transported to the air bubble cleaning machine via the conveyor belt for cleaning. The cleaning solution is salt water with a concentration of 2%, and the clea...

Embodiment 2

[0040] combine figure 1 As shown, a method for preparing dried cherry tomatoes without color-protecting agent mainly includes the following steps: raw material cleaning, screening, secondary cleaning, cutting, sterilization, coating, air-drying and freeze-drying;

[0041] (1) Raw material cleaning: Use a high-pressure cleaner to clean the raw material to remove sediment and foreign matter on the surface of the raw material;

[0042] (2) Screening: remove the inedible parts of the raw materials, classify the raw materials, select qualified raw materials, and then process them into certain specifications. The screening process is carried out on the conveyor belt, and the low-temperature water is continuously sprayed during the screening process;

[0043] (3) Secondary cleaning: the screened raw materials are transported to the air bubble cleaning machine through the conveyor belt for cleaning. The cleaning solution is salt water with a concentration of 1%, and the cleaning time ...

Embodiment 3

[0050] combine figure 1 As shown, a method for preparing dried celery without adding a color-protecting agent mainly includes the following steps: raw material cleaning, screening, secondary cleaning, cutting, sterilization, coating, air-drying and freeze-drying;

[0051] (1) Raw material cleaning: Use a high-pressure cleaner to clean the raw material to remove sediment and foreign matter on the surface of the raw material;

[0052] (2) Screening: remove the inedible parts of the raw materials, classify the raw materials, select qualified raw materials, and then process them into certain specifications. The screening process is carried out on the conveyor belt, and the low-temperature water is continuously sprayed during the screening process;

[0053] (3) Secondary cleaning: transfer the screened raw materials to the air bubble cleaning machine via the conveyor belt for cleaning. The cleaning solution is salt water with a concentration of 10%, and the cleaning time is 5 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com