Fiber collector, oil absorbing material using said collector and manufacturing method of fiber collector

A technology of fiber aggregation and assembly, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as complex manufacturing methods, and achieve the effect of strong oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

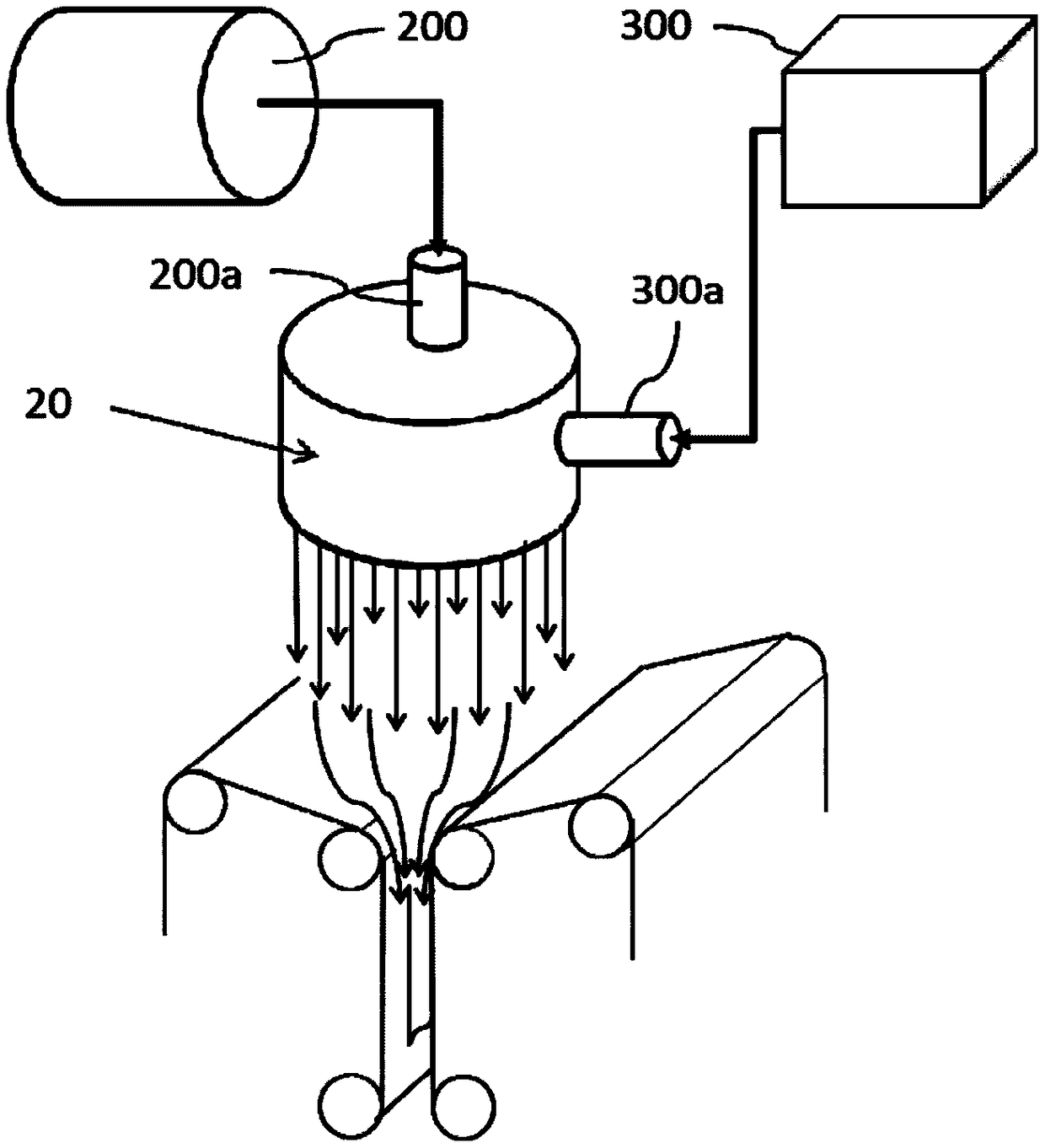

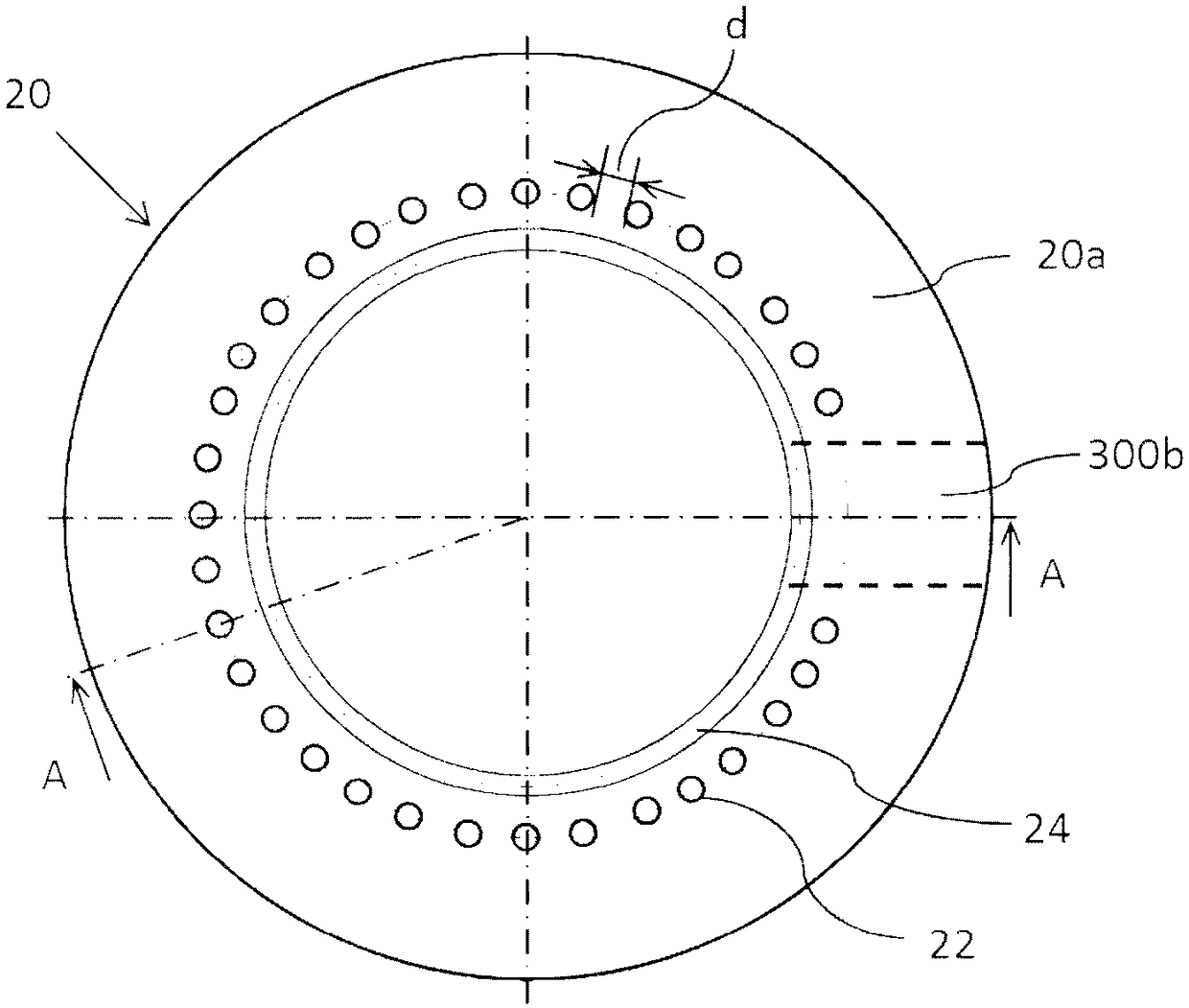

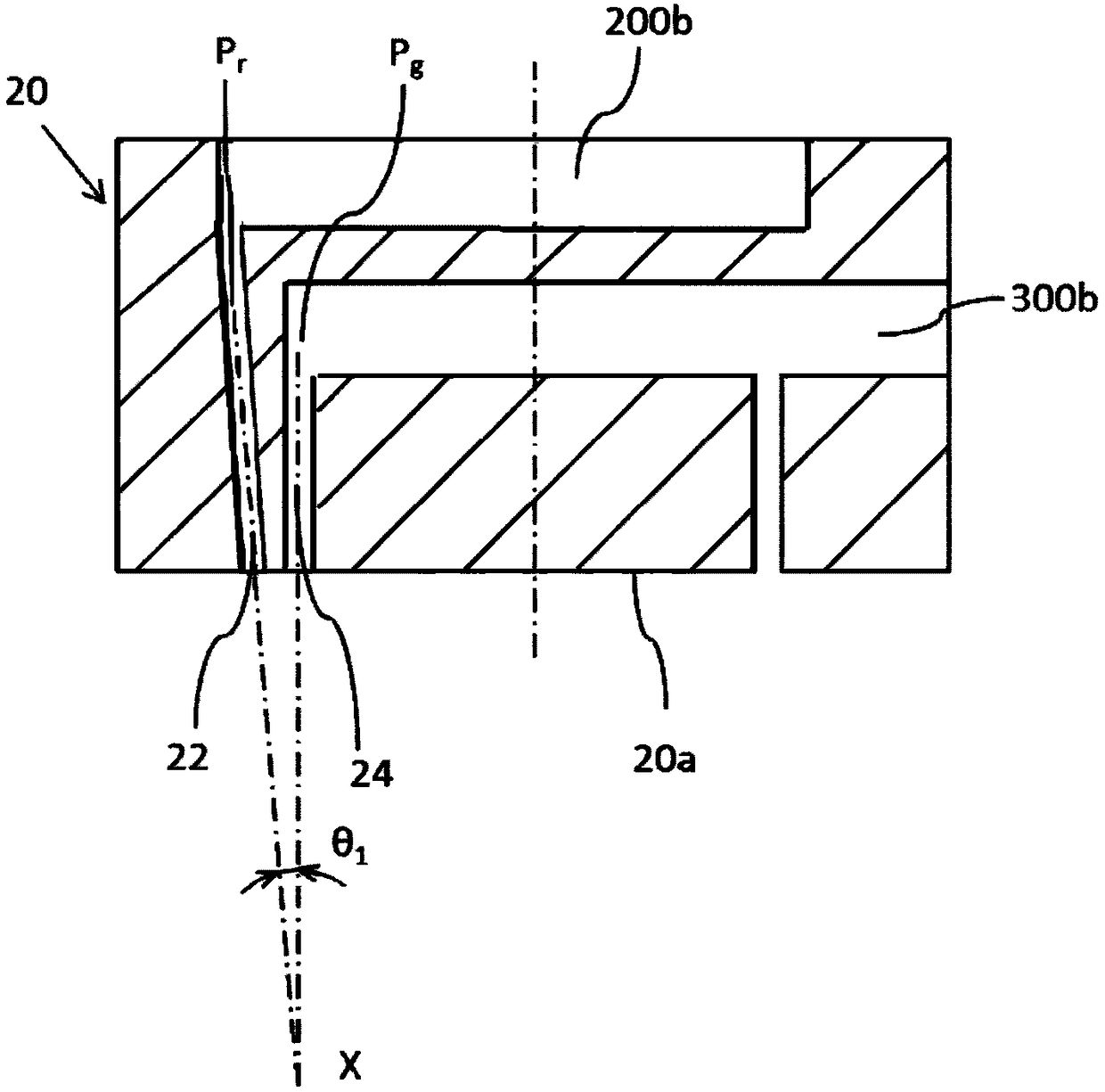

[0070] The extruder for melting polypropylene resin is equipped with figure 2 The nozzle head 20 for melt blowing shown is used, and the nozzle head having the following nozzle conditions is used, and the spinning is performed under the following operating conditions.

[0071]

[0072]

[0073]

[0074]

[0075]

[0076] Here, the temperature of the nozzle is about 300°C. From the beginning of spinning to the end of spinning, basically no temperature change can be observed, and it is almost constant.

[0077] The melted polypropylene resin is spouted from the nozzle for melt blowing, stretched by the high-speed and high-temperature airflow blown from the hot air nozzle, and the fine resin fibers are entangled with each other, twisted into a rope, and then piled up on the conveyor belt. fiber aggregates.

[0078] Figure 4 This is an example of a photograph of a fiber assembly including fiber bundles taken with a low-magnification microscope. The fiber assembly as...

Embodiment 2

[0083] The extruder for melting polypropylene resin is equipped with figure 2 The nozzle head 20 for melt blowing shown is used, and the nozzle head having the following nozzle conditions is used, and the spinning is performed under the following operating conditions. Here, items of head conditions and operating conditions that are the same as in Example 1 are omitted.

[0084] Assembled on the extruder figure 2 The nozzle 20 for melt-blowing is shown, and the nozzle having the following nozzle conditions is used, and the melted polypropylene resin is spun under the following operating conditions. Here, the items of head conditions and operating conditions that are the same as those in Embodiment 1 are omitted.

[0085]

[0086] Liquid nozzle hole φ0.35mm×78

[0087] Liquid nozzle interval 1.15mm

[0088]

[0089] Resin output 5~13kg / hr

[0090] Hot air (air) temperature 330°C

[0091] The temperature of the nozzle here is 330° C. From the beginning of spinning to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com