Dacromet production line inner side plate

A production line, Dacromet technology, applied in the direction of sheet/board, thin plate connection, thermal insulation, etc., can solve the problems affecting the overall performance of the production line, increase the maintenance cost of the production line, affect the thermal insulation performance, etc., to maintain stable working performance and reduce production. The effect of maintenance cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

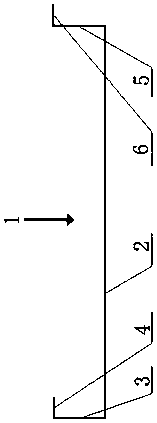

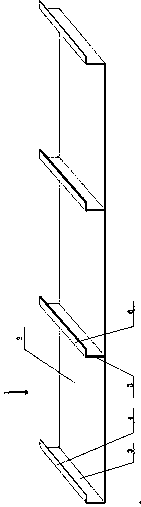

[0024] The inner panel of the Dacromet production line as shown in the figure includes three single inner panels 1, the single inner panel 1 is composed of a heat insulation board 2, a first folding arm 3, a first lap 4, and a second folding arm 5 and the second joint 6, one end of the heat shield 2 is perpendicular to the first folding arm 3, and the other end is perpendicular to the second folding arm 5, the first folding arm 2 and the second folding arm 5 are parallel to each other, the first One end of the lap 4 is connected to the first folding arm 3 and parallel to the heat insulation board 2, one end of the second lap 6 is connected to the second folding arm 5 and parallel to the heat insulation board 2, the first lap 4 and the second lap are The extending directions of the free ends of 6 are consistent.

[0025] In this embodiment, one end of the heat shield 2 is vertically connected to the first folding arm 3 , and the other end is vertically connected to the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com