Preparation method of conductive partitioned polyacrylonitrile spinal catheter

A polyacrylonitrile, partitioned technology, applied in the field of medical materials, can solve problems such as unsatisfactory spinal cord repair results and differences in histological structure, and achieve the effect of good electrical conductivity and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the present embodiment comprises the following steps:

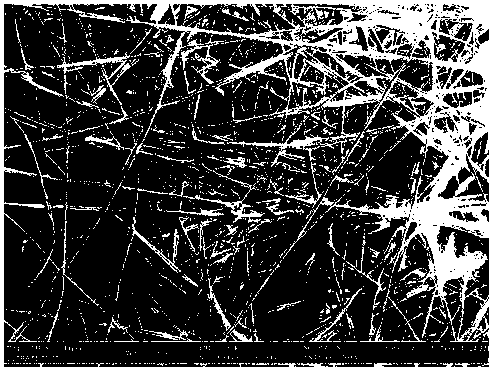

[0025] Weigh 0.5 g of terephthalic acid (PTA) powder and mix it into 10 mL of DMF, and stir at room temperature for 10 min until completely dissolved. Weigh 1 g of polyacrylonitrile (PAN) powder and dissolve it in the solution, heat and stir at 80 °C for 3 h to obtain a slightly yellow polyacrylonitrile spinning solution. The above solution was spun into nanofibers by electrospinning technique, such as figure 1 . The specific parameters are: the voltage is 12 kV, the spinning vessel used is a 10 mL plastic syringe with a vacuum diameter of 20 mm, the flow rate is 0.08 mm / min, the receiving distance is 15 cm, and the spinning time is 10 h. The polyacrylonitrile nanofibers deposited on the collector were placed in an oven at 60 °C for 24 h.

[0026] Disperse 2 g of the above-mentioned polyacrylonitrile nanofibers in 50 mL of deionized water, and stir at a high speed of 18000 r / min for 10 min to obtai...

Embodiment 2

[0028] Embodiment 2, this embodiment comprises the following steps:

[0029] Weigh 0.3 g of terephthalic acid (PTA) powder and mix it into 10 mL of DMF, and stir at room temperature for 10 min until completely dissolved. Weighed 1.2 g polyacrylonitrile (PAN) powder and dissolved it in the solution, heated and stirred at 70 °C for 3 h to obtain a slightly yellow polyacrylonitrile spinning solution. The above solution was spun into nanofibers by electrospinning technology, and the specific parameters were as follows: the voltage was 10 kV, the spinning vessel used was a 10 mL plastic syringe with a vacuum diameter of 20 mm, the flow rate was 0.05 mm / min, and the receiving distance was 10 cm. The spinning time was 8 h. The polyacrylonitrile nanofibers deposited on the collector were placed in an oven at 60 °C for 24 h.

[0030] Disperse 3 g of the above-mentioned polyacrylonitrile nanofibers in 50 mL of deionized water, and stir at a high speed of 18000 r / min for 30 min to obta...

Embodiment 3

[0032] Embodiment 3, this embodiment comprises the following steps:

[0033] Weigh 0.5 g of terephthalic acid (PTA) powder and mix it into 10 mL of DMF, and stir at room temperature for 10 min until completely dissolved. Weighed 1.2 g of polyacrylonitrile (PAN) powder and mixed it into 10 mL of DMF, heated and stirred at 80 °C for 3 h to obtain a slightly yellow polyacrylonitrile spinning solution. The above solution was spun into nanofibers by electrospinning technology. The specific parameters were as follows: the voltage was 15 kV, the spinning vessel used was a 10 mL plastic syringe with a vacuum diameter of 20 mm, the flow rate was 0.10 mm / min, and the receiving distance was 20 cm. The spinning time was 8 h. The polyacrylonitrile nanofibers deposited on the collector were placed in an oven at 60 °C for 24 h.

[0034] Disperse 2 g of the above-mentioned polyacrylonitrile nanofibers in 50 mL of deionized water, and stir at a high speed of 21000 r / min for 30 min to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com