Environment-friendly high-quality sand making building station system

A high-quality, environmentally friendly technology, applied in the field of construction machinery, can solve the problems of poor performance of powder separation equipment, low crushing efficiency, poor quality of finished products, etc., to achieve the effect of improving production capacity, high crushing efficiency and accurate screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

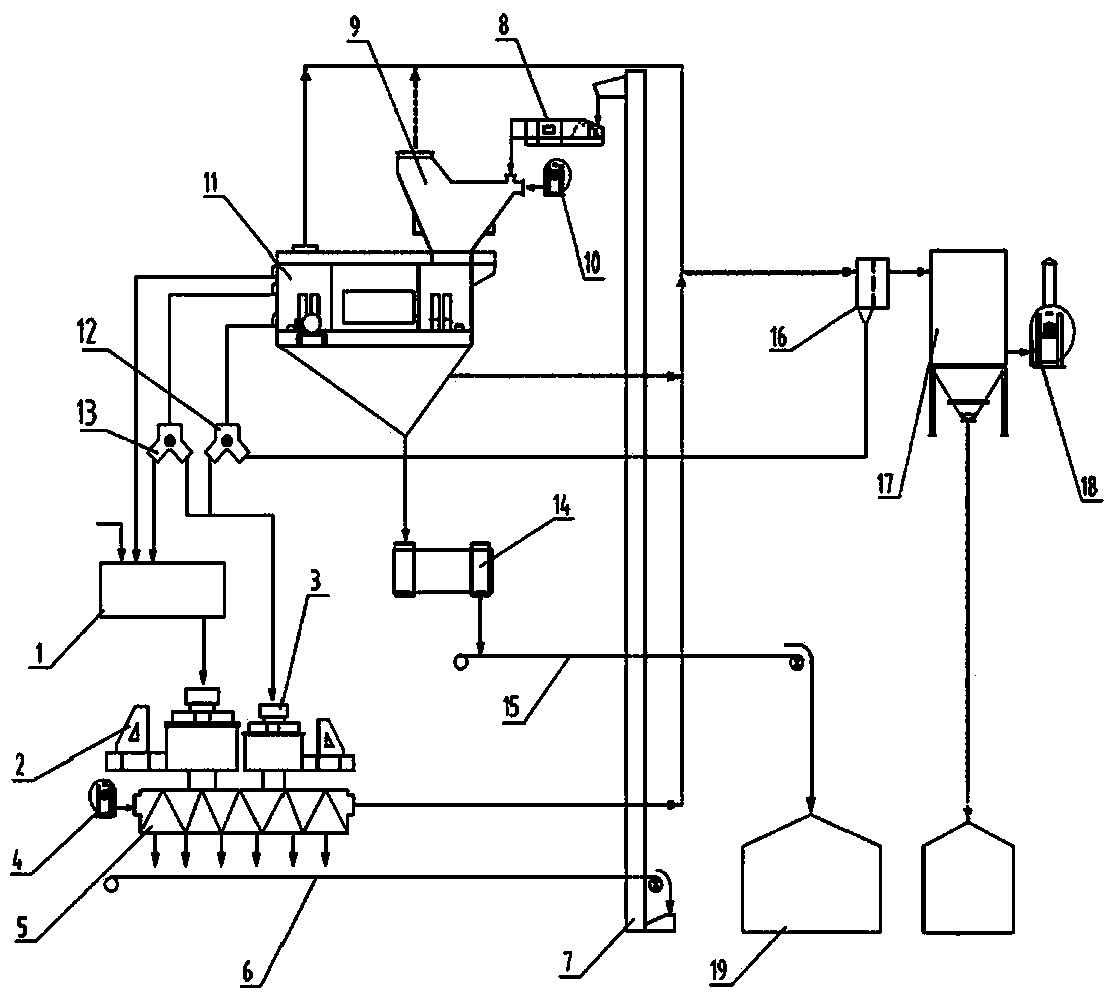

[0024] figure 1 Middle: feed collection bin 1, overflow waterfall type vertical shaft crusher 2, high-speed vertical shaft crusher 3, primary powder separator blower 4, primary powder separator 5, plate conveyor 6, bucket elevator 7, vibration disperser 8, impact Type composite powder separator 9, impact type composite powder separator blower 10, three-axis horizontal oval sieve 11, No. 2 three-way valve 12, No. 1 three-way valve 13, wet mixer 14, inertial dust separator 16, dust collector 17. Special blower for dust collector 18. Finished sand bin 19.

[0025] An environment-friendly high-quality sand making station system, the discharge port of the feed collection bin 1 is connected to the feed port of the overflow-type vertical shaft crusher 2 through a pipeline, and the discharge port of the overflow-type vertical shaft crusher 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com