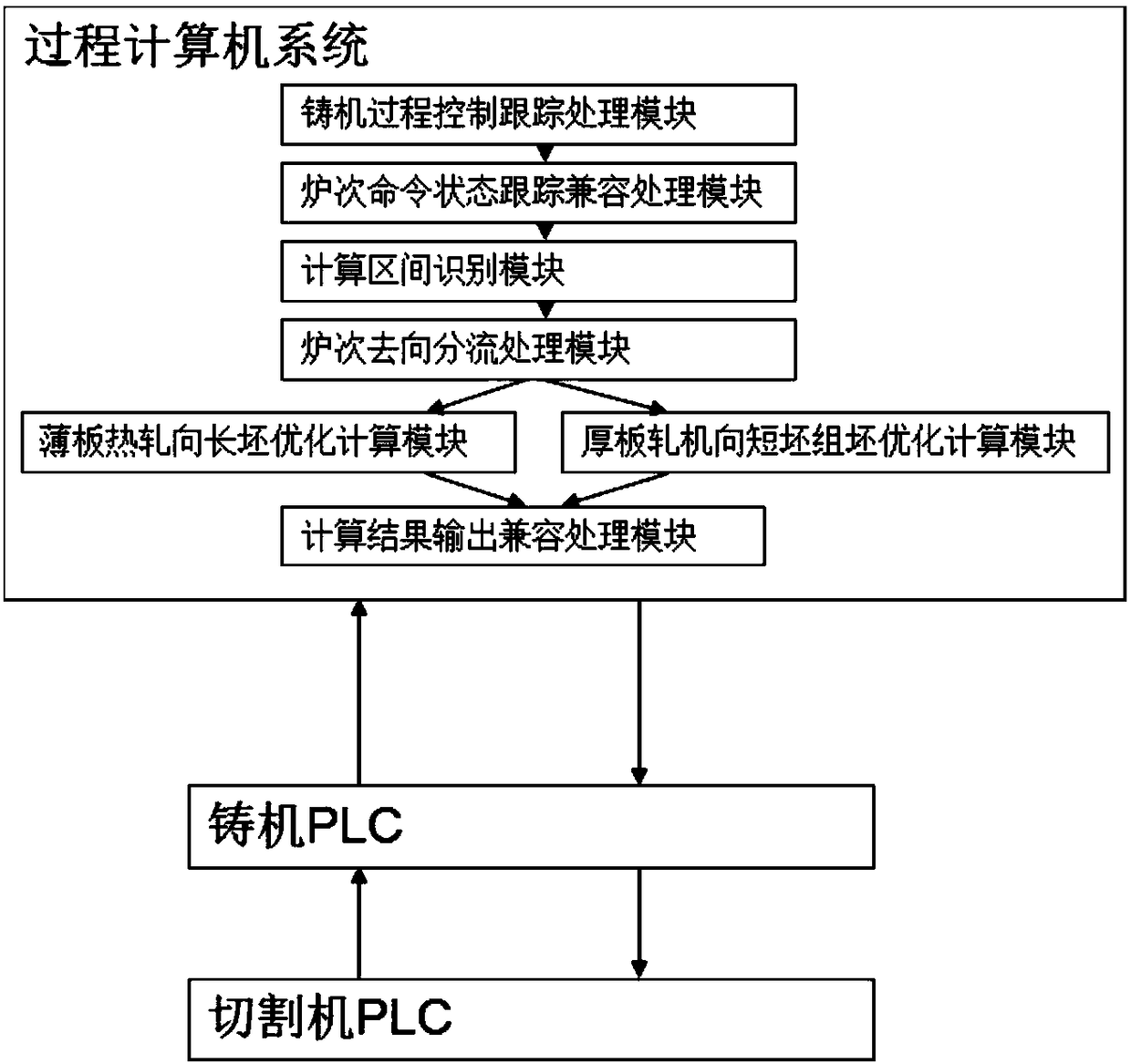

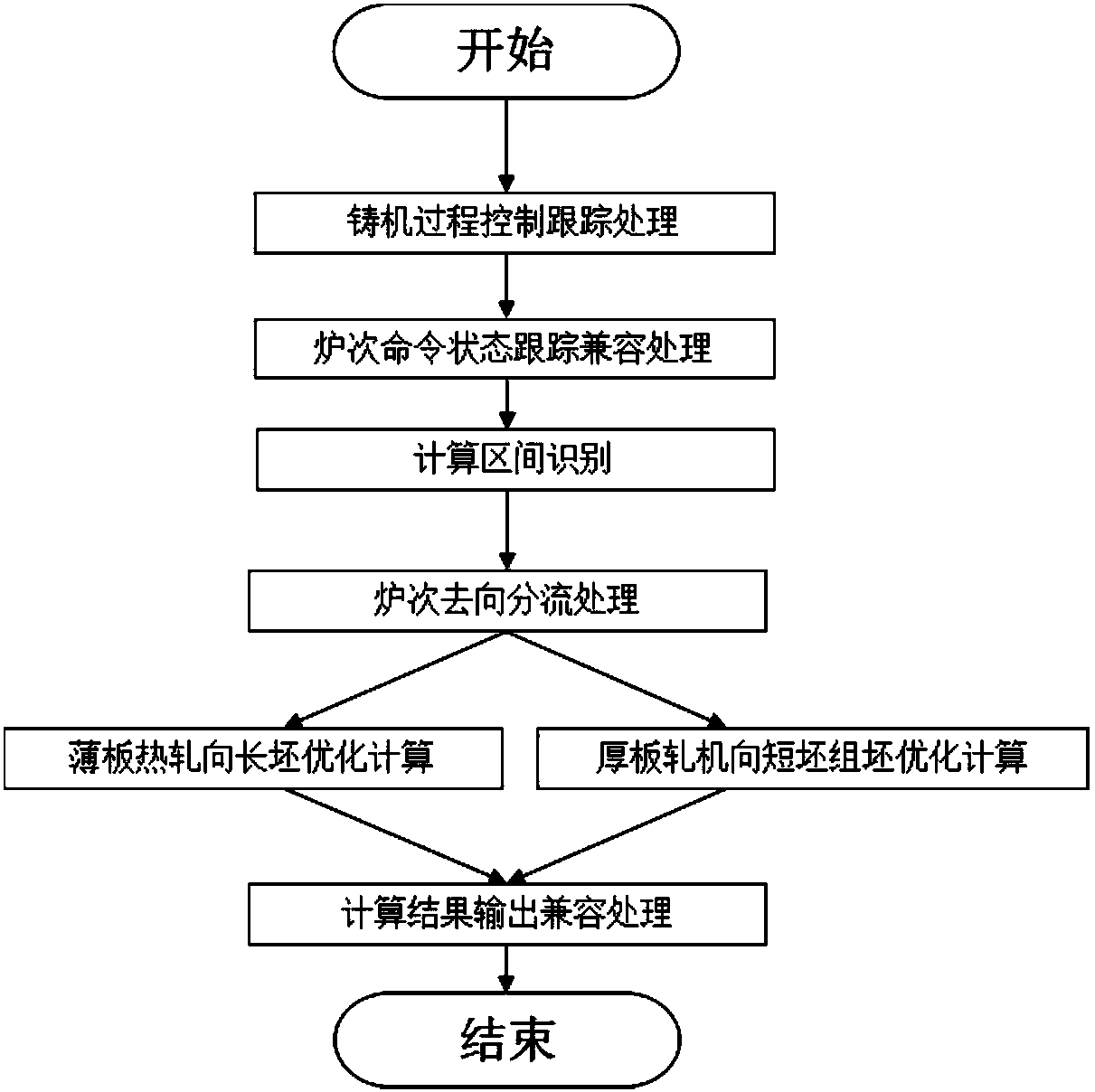

Continuous casting billet cutting control system and control method thereof

A technology of a control system and a control method, which is applied to the continuous casting slab cutting control system and the control field thereof, can solve the problems of inability to consider the compatibility of several command systems, low work efficiency, and low precision of sizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] Embodiment 1: Production embodiment of thin plate single furnace

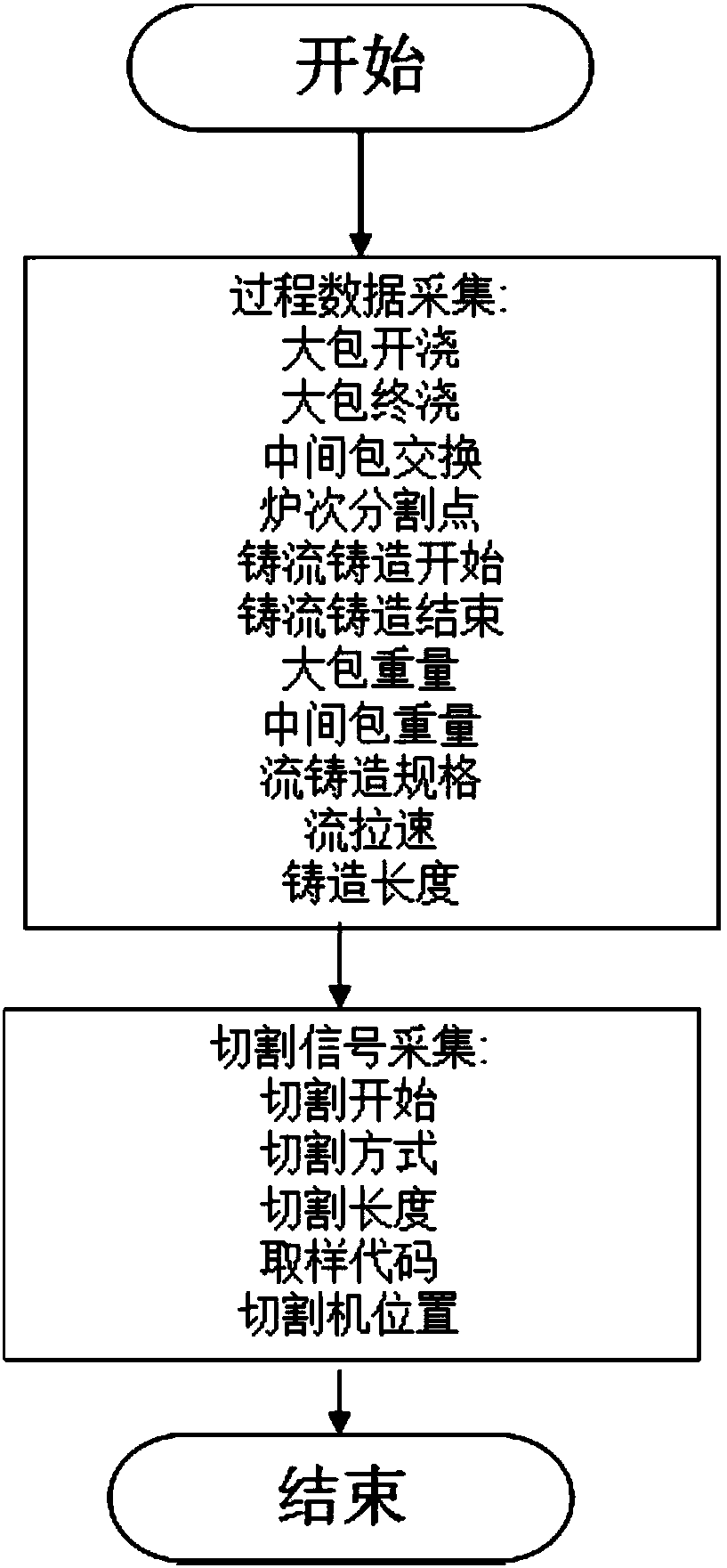

[0166] (1) Casting machine process control tracking processing

[0167] Ladle weight: 120 tons, tundish weight: 60 tons, casting width: 1600 mm, casting thickness: 250 mm, casting speed: 100 mm / min.

[0168] (2) Furnace command state tracking compatible processing

[0169] L hot billet = L cold billet × F (1)

[0170] F: heat expansion coefficient of steel type = 1.01

[0171]

[0172] (3) Calculation interval identification

[0173] Calculation of steel flow per unit of single flow:

[0174] TH=T×W×S×G=3.12 tons / minute (2)

[0175] Among them: TH: single-strand unit steel flow, T: slab thickness = 250 / 1000, W: slab width = 1600 / 1000, S: strand casting speed = 100 / 100, G: slab specific gravity = 7.8

[0176] Calculation and processing of molten steel amount for calculation:

[0177] TT=LW+TW-LR=170 tons (3)

[0178] Among them: TT: Calculate the amount of molten steel, LW: Ladle molten steel w...

Embodiment 2

[0215] Example 2: Production Example of Thick Plate Single Furnace

[0216] (1) Casting machine process control tracking processing

[0217] Ladle weight: 120 tons, tundish weight: 60 tons, casting width: 1600 mm, casting thickness: 250 mm, casting speed: 100 mm / min.

[0218] (2) Furnace command state tracking compatible processing

[0219] L hot billet = L cold billet × F (1)

[0220] F: heat expansion coefficient of steel type = 1.01

[0221]

[0222] (3) Calculation interval identification

[0223] Calculation of steel flow per unit of single flow:

[0224] TH=T×W×S×G=3.12 tons / minute (2)

[0225] Among them: TH: single-strand unit steel flow, T: slab thickness = 250 / 1000, W: slab width = 1600 / 1000, S: strand casting speed = 100 / 100, G: slab specific gravity = 7.8

[0226] Calculation and processing of molten steel amount for calculation:

[0227] TT=LW+TW-LR=170 tons (3)

[0228] Among them: TT: Calculate the amount of molten steel, LW: Ladle molten steel weight...

Embodiment 3

[0274] Example 3: production example of continuous casting in two furnaces of thin plate and thick plate

[0275] (1) Casting machine process control tracking processing

[0276] Ladle weight: 120 tons, tundish weight: 60 tons, casting width: 1600 mm, casting thickness: 250 mm, casting speed: 100 mm / min. Furnace split point 10 meters. The calculated length of the front furnace is 10 meters, and the ladle and tundish molten steel is the thick plate molten steel of the rear furnace. [0, 10 meters] is the heat of thin plate, [10 meters,] is the heat of thick plate.

[0277] (2) Furnace command state tracking compatible processing

[0278] L hot billet = L cold billet × F (1)

[0279] F: heat expansion coefficient of steel type = 1.01

[0280] Sheet heat cutting command:

[0281]

[0282] Thick plate heat cutting command:

[0283]

[0284]

[0285] (3) Calculation interval identification

[0286] Calculation of steel flow per unit of single flow:

[0287] TH=T×W×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com