3D printing metal powder material manufacturing equipment and method

A metal powder, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of manual regular cleaning, high production cost, and reduce the service life of the filter element, so as to improve the use effect and service life, improve energy utilization rate, high The effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

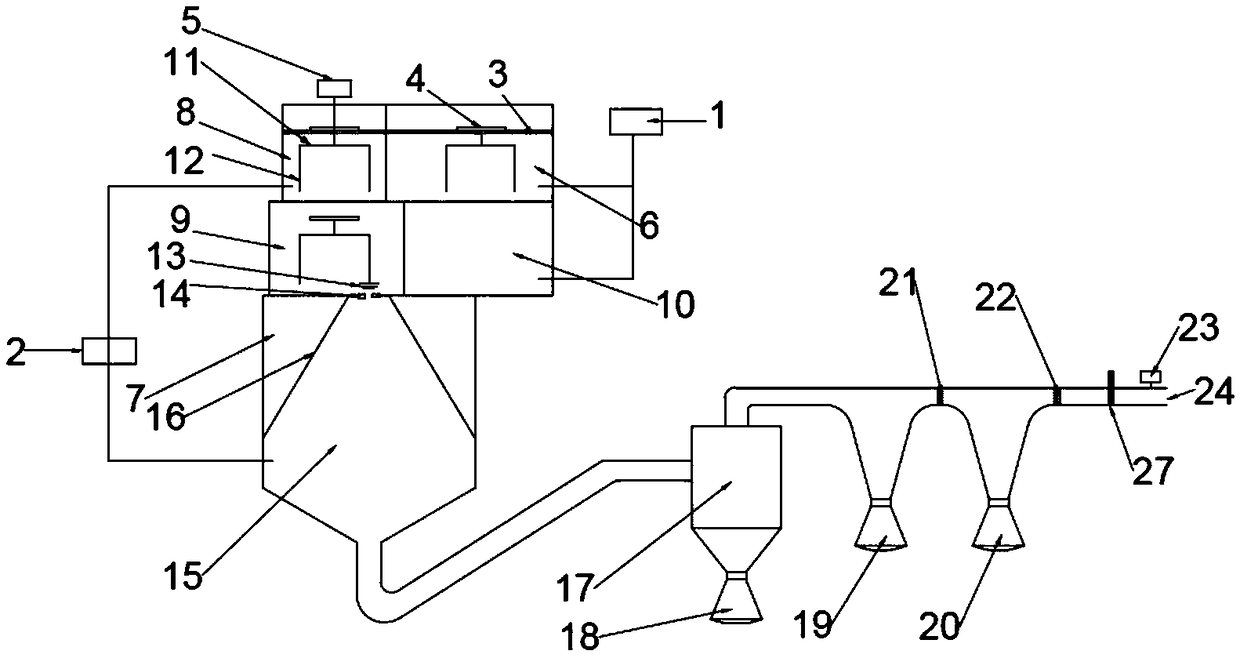

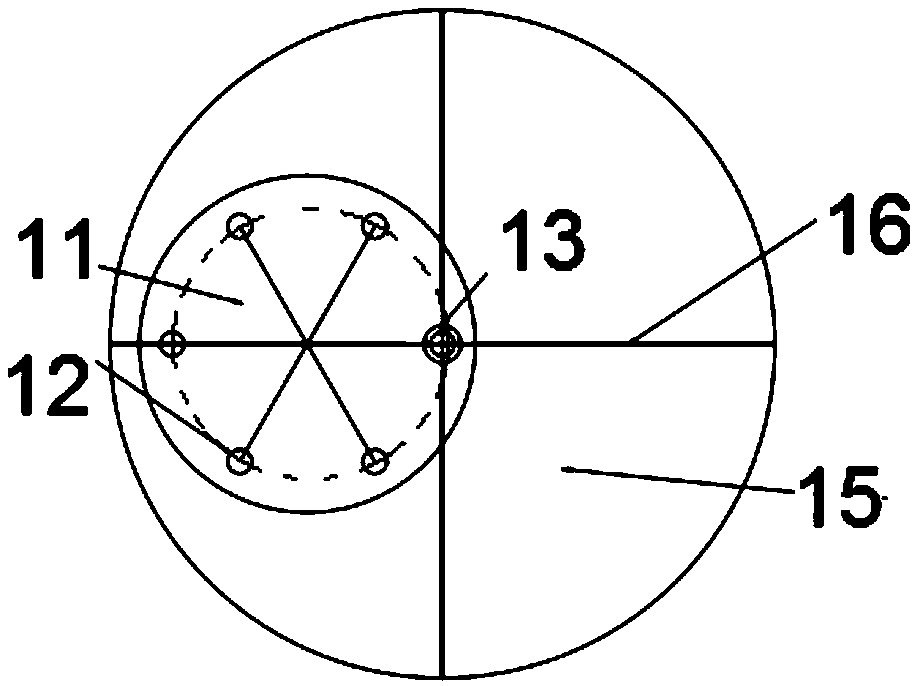

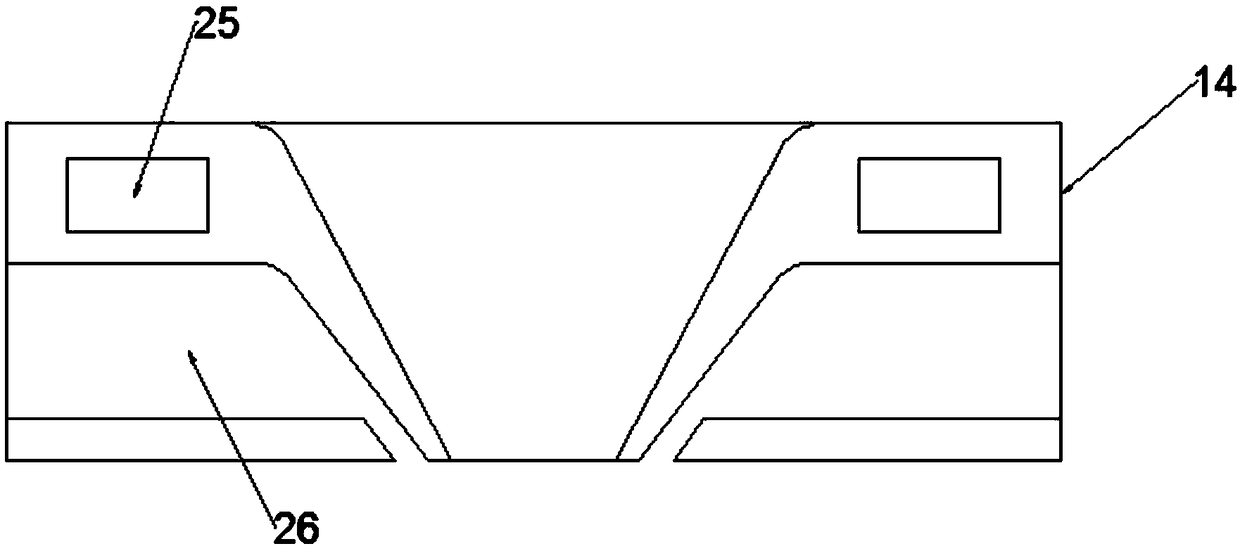

[0037] First, the entire configuration of an example of a 3D printing metal powder material manufacturing device according to the present invention will be described. A new high-efficiency manufacturing equipment for preparing 3D printing metal powder materials includes a feeding device, a melting device, an atomizing device, and a powder collection system. The feeding device, melting device, and atomizing device are arranged in sequence from top to bottom. The discharge port of the chemical device is connected to the feed port of the powder collection system through a pipeline, and the metal powder is output.

[0038] Such as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap