Preparation method for chromium-doped cobalt powder

A technology for cobalt powder and powder, applied in the field of metal cobalt powder preparation, can solve the problems of poor dispersibility and uneven particle size of doped cobalt powder, and achieve the effects of good dispersibility, good fluidity and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

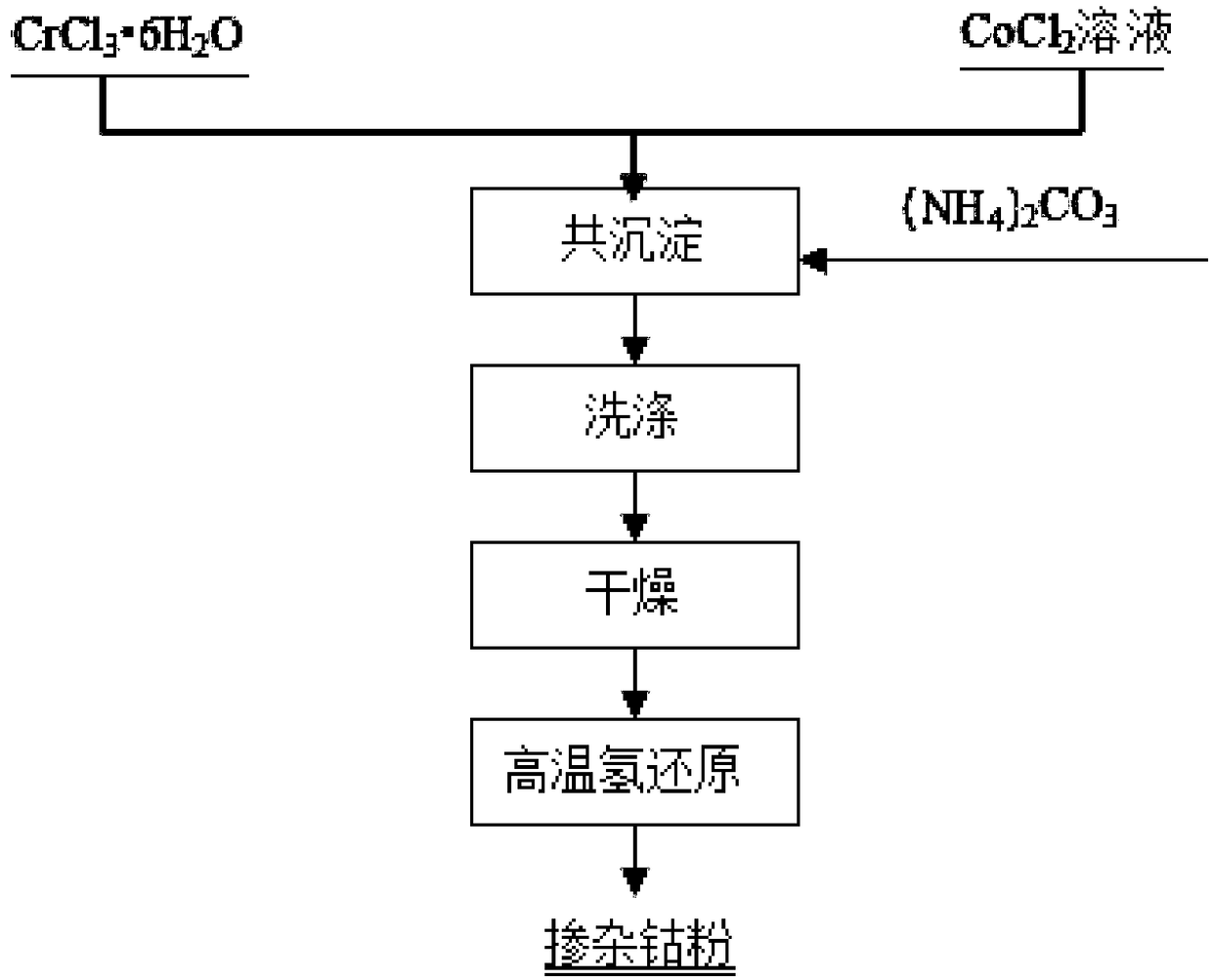

[0039] The invention provides a kind of preparation method of the cobalt powder doped with chromium, this method realizes by following steps:

[0040] Step 1, get a certain amount of cobalt chloride, add 50~70 DEG C of water to it, and stir to dissolve, the cobalt concentration that is mixed with is the cobalt chloride solution of 80~140g / L; Get a certain amount of ammonium bicarbonate, Add water at 50-60°C, stir and dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 160-230g / L for later use; use water at a certain temperature to prepare cobalt chloride and ammonium bicarbonate solutions respectively, so that Cobalt chloride and ammonium bicarbonate have been fully dissolved, and the dispersibility of cobalt ions in the cobalt chloride solution and the dispersibility of carbonate ions in the ammonium bicarbonate solution have also been improved;

[0041] Step 2, add chromium chloride hexahydrate (CrCl 3 ·6H 2 O), stir evenly, obtain doped...

Embodiment 1

[0059] Step 1) Get a certain amount of cobalt chloride and put it into the solution tank, add water at 50°C therein, and stir and dissolve, and prepare a cobalt chloride solution whose concentration of cobalt (Co) is 90g / L; then take a certain amount Put the ammonium bicarbonate into another solution tank, add water at 50°C therein, and stir to dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 180g / L for subsequent use;

[0060] Step 2) take 3L prepared cobalt chloride solution, and add 7.69gCrCl 3 ·6H 2 0, stir evenly, the concentration that obtains chromium (Cr) is 0.5g / L (500ppm) doping cobalt chloride solution;

[0061] Step 3) degreasing the prepared ammonium bicarbonate solution and the doped cobalt chloride solution respectively;

[0062] Step 4) Add 1.5L of pure water into the reactor as the bottom liquid, and heat the pure water to make the temperature of the bottom liquid reach 30°C, then add the doped cobalt chloride solution ...

Embodiment 2

[0069] Step 1) Get a certain amount of cobalt chloride and put it into the solution tank, add water at 60°C therein, and stir and dissolve to prepare a cobalt chloride solution whose concentration of cobalt (Co) is 100g / L; then take a certain amount Put the ammonium bicarbonate into another solution tank, add water at 55°C therein, and stir to dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 190g / L for subsequent use;

[0070] Step 2) Take 3L of prepared cobalt chloride solution, and add 4.61gCrCl 3 ·6H 2 0, stir evenly, obtain the doping cobalt chloride solution that the concentration of chromium (Cr) is 0.3g / L (300ppm);

[0071] Step 3) degreasing the prepared ammonium bicarbonate solution and the doped cobalt chloride solution respectively;

[0072] Step 4) Add 1.5L of pure water into the reactor as the bottom liquid, and heat the pure water so that the temperature of the bottom liquid reaches 40°C, and then add the doped cobalt chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com