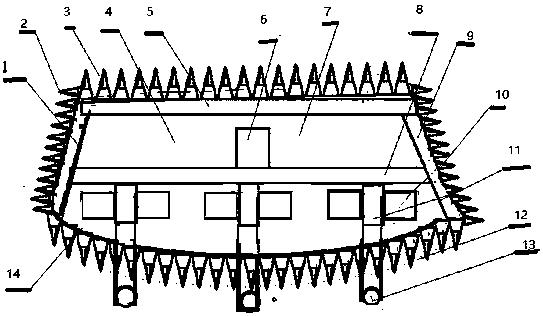

Butterfly-shaped jet-propelled aircraft capable of taking off and landing vertically

A vertical take-off and landing, jet-type technology, applied to vertical take-off and landing aircraft, aircraft, jet power plant, etc., can solve the problems of complex structure and inconvenient implementation of the compressed air supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

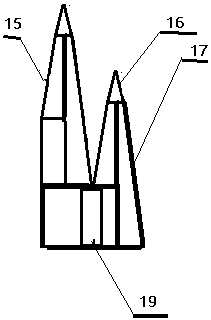

[0024] When a vertical take-off and landing butterfly jet aircraft of the present invention takes off, first use the rising support wheel to make the aircraft rise, and simultaneously install and start the downward jet of the engine at the center to make the aircraft rise vertically. As the aircraft rises faster, the pressurized air supply device on the top of the aircraft starts to work, injecting pressurized gas into the take-off air tank, and when the aircraft reaches the desired altitude, start the engines around the aircraft and adjust the engine nozzles direction, so that the aircraft can achieve ultra-high-sonic flight under the condition of silence; at the same time, the engine in the center is turned off, and the air supply and fuel supply of each set of engines are adjusted according to the needs of the speed during flight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com