Polymerization method for toluylene bisazo dye

A disazo dye and polymerization technology, applied in organic chemistry, sulfonate preparation, etc., can solve the problems of high cost, poor adaptability and diversity, and influence on polymerization reaction, and achieve large operating freedom and adaptability Strong, product-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

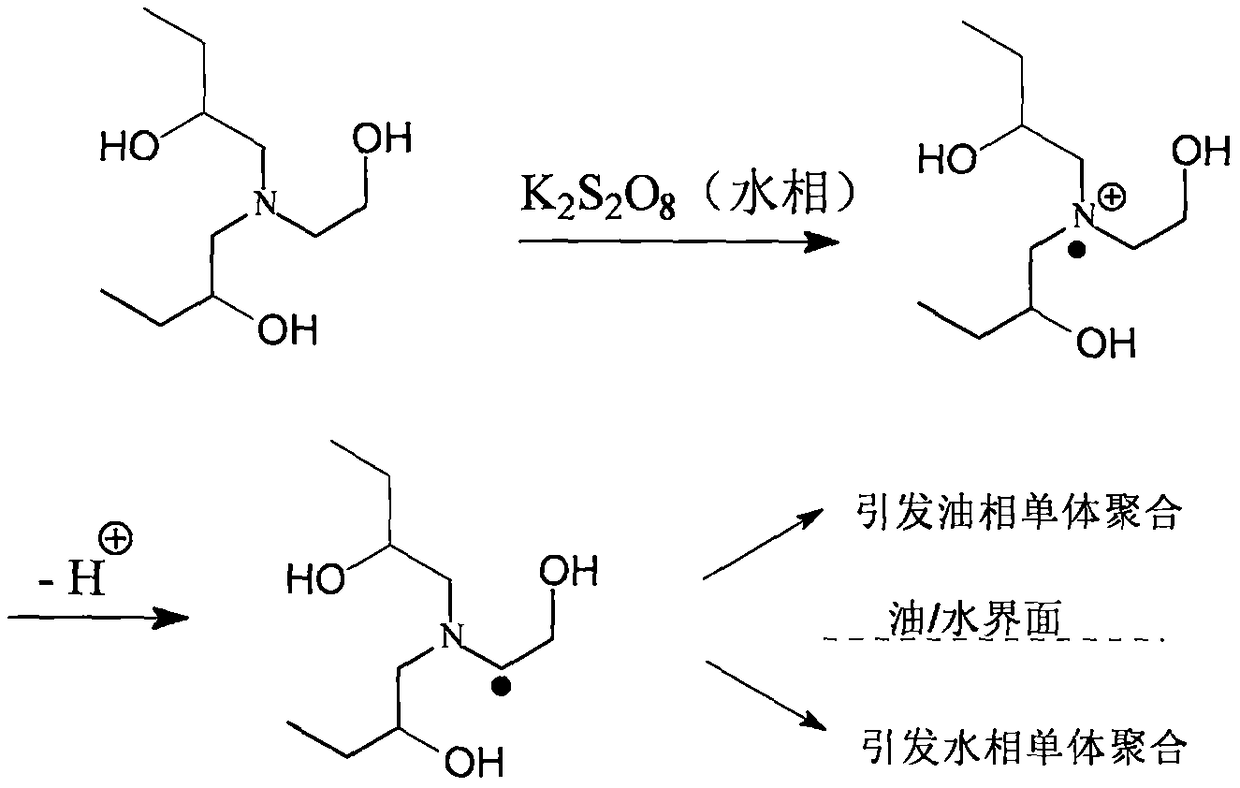

[0020] Preparation of functional initiators:

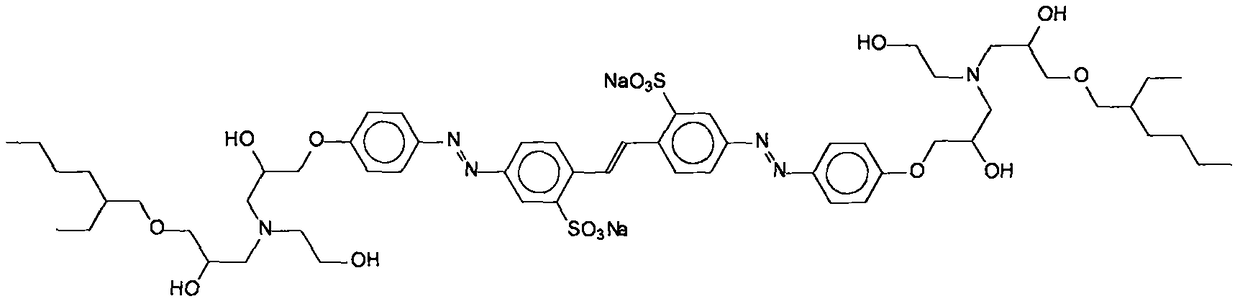

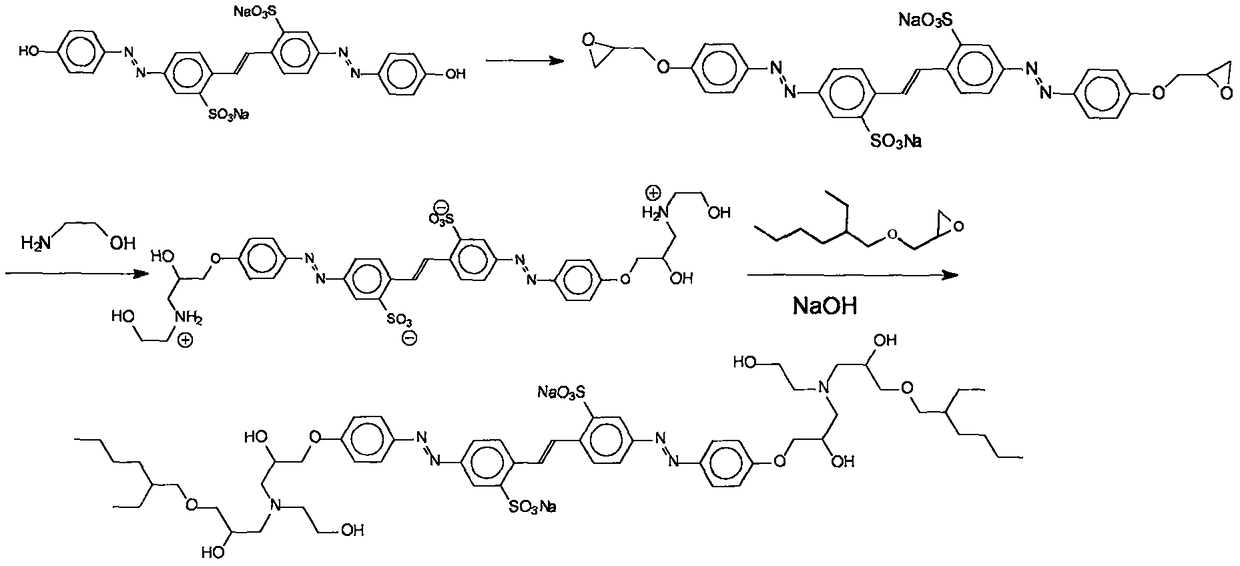

[0021] With stilbene bis-azophenol as the starting material, this material has been commercialized, so its preparation has a ready-made method, which will not be repeated here. The following are the specific preparation steps:

[0022] 1) Dissolve 0.1mol stilbene bis-azophenol in 400ml water, then add 0.2mol NaOH, gradually add 0.2mol epichlorohydrin under stirring, control the temperature of the reaction solution in the range of 50-55°C, and the reaction time at 3 ~4 hours, after completion, add 0.22mol ethanolamine, continue to react at 30~35°C for 2~3 hours, then acidify with hydrochloric acid until the pH value is in the range of 4.0~4.5, a large amount of yellow precipitate appears, collect the precipitated substance and wash it with clean water washing, vacuum drying after filtration;

[0023] 2) Dissolve the product obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com