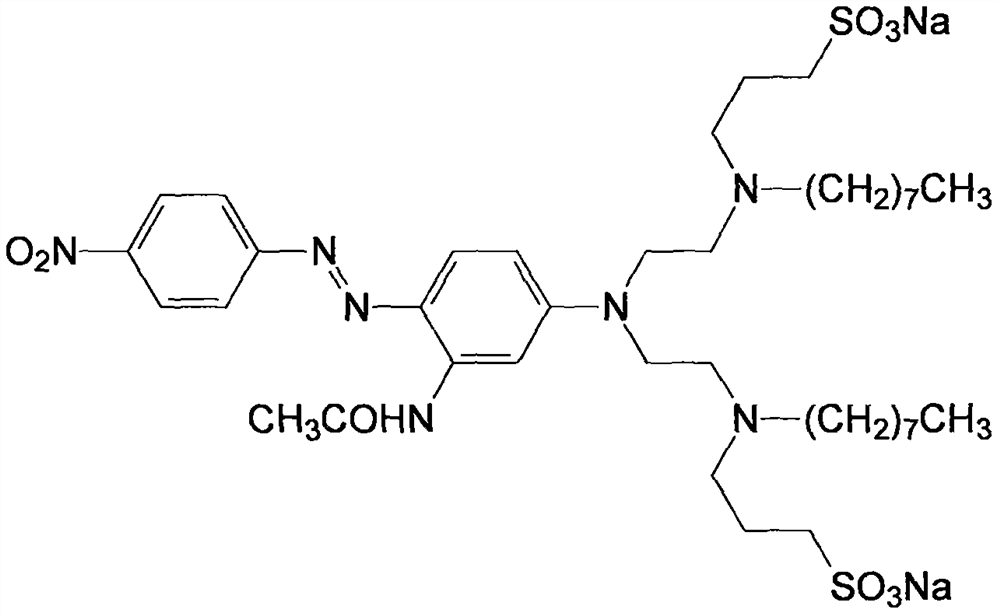

A polymerization method of disperse scarlet dye s-bwfl

A S-BWFL, polymerization technology, applied in the field of functional polymer material synthesis, can solve the problems of high cost, poor adaptability and diversity, affecting the polymerization reaction, etc., to achieve high conversion rate, strong adaptability, and pure product. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

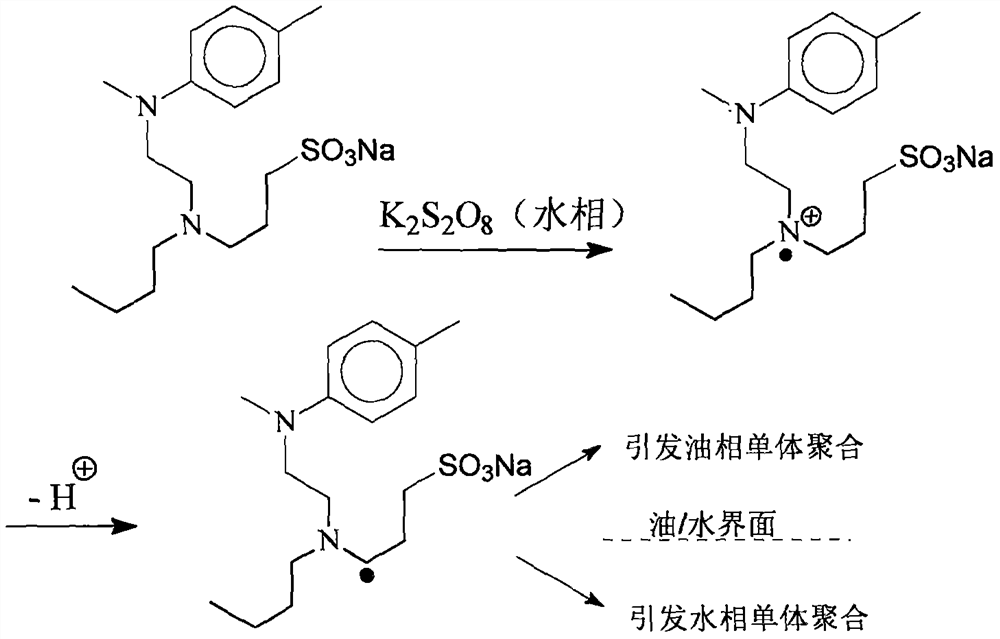

[0020] Preparation of functional initiators:

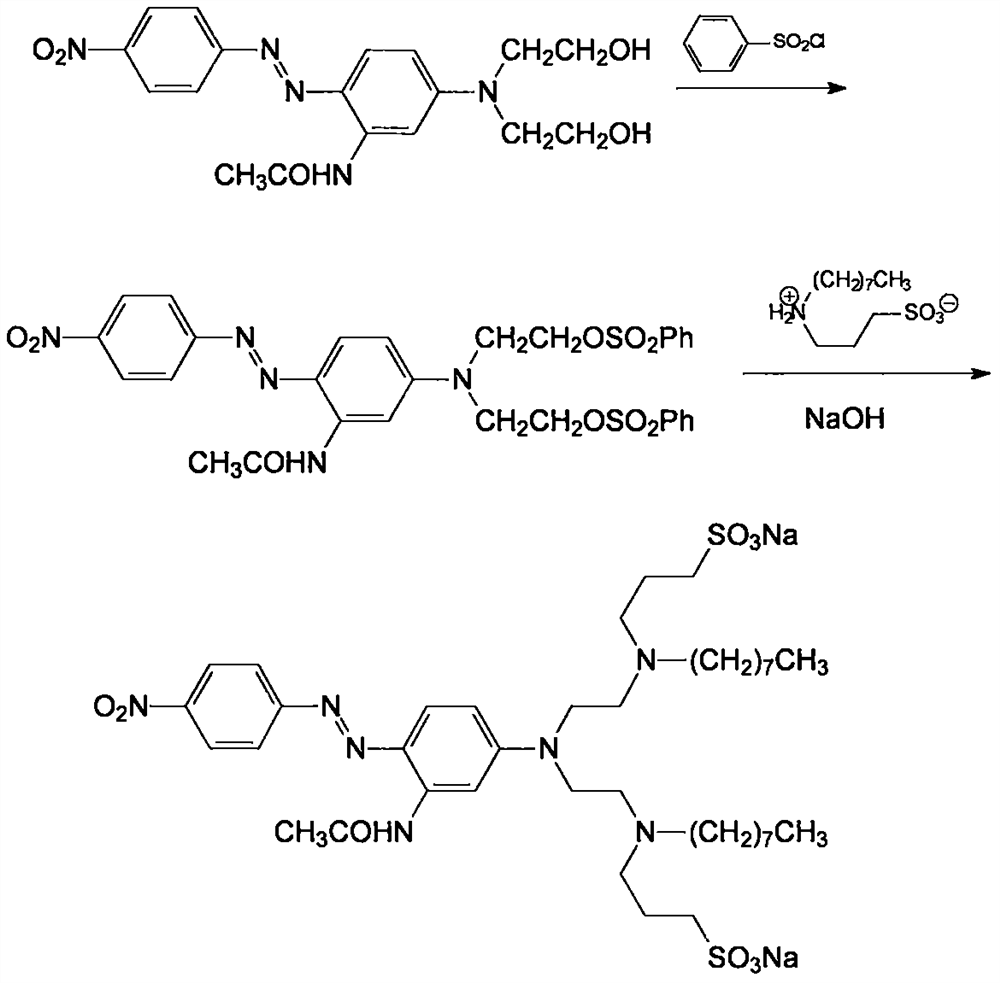

[0021] Using an intermediate product in the preparation of disperse scarlet dye as a starting material, this material has been commercialized, so its preparation has a ready-made method, which will not be repeated here. The following are the specific preparation steps:

[0022] 1) Dissolve 0.1mol of azo dye in 300ml of dioxane, gradually add 0.21mol of benzenesulfonyl chloride and 0.21mol of pyridine under stirring, control the temperature of the reaction solution within the range of 30-35°C, and the reaction time within 1-2 hours After the reaction is completed, pour the reaction solution into cold water, filter the product after precipitation, wash the precipitation with water, and then dry it for later use;

[0023] 2) Dissolve 0.2mol of octylamine in 100ml of absolute ethanol, slowly add 0.2mol of propane sultone under stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com