Leadless PVC pipe and preparation method thereof

A technology for PVC pipes and raw materials, applied in the field of lead-free PVC pipes and their preparation, can solve the problems of poor calcium and zinc and rare earth stability in the later stage, health hazards of production workers, and easy to cause pollution, etc., and achieve good early-stage hue and reliability. High and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

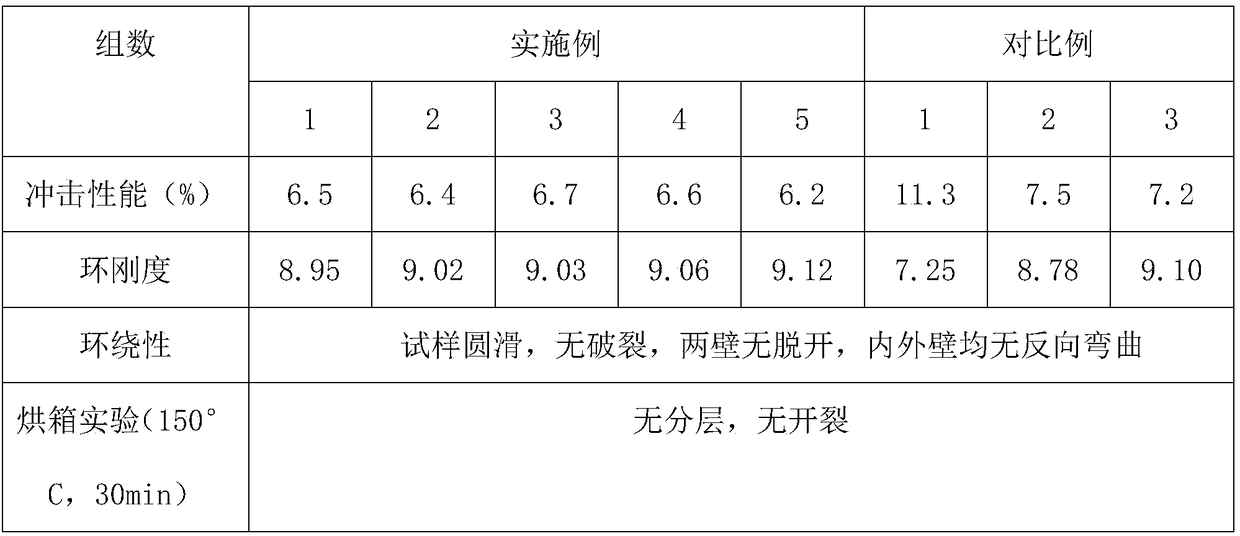

Examples

Embodiment 1

[0026] In Example 1, a lead-free PVC pipe is made of the following raw materials in parts by weight: 80 parts of polyvinyl chloride, 1 part of titanium dioxide, 6 parts of bamboo activated carbon powder, 3 parts of filler, 2 parts of lubricant, 1 part of toughening agent.

[0027] The preparation method of above-mentioned lead-free PVC pipe material, comprises the steps:

[0028] (1) Preparation of bamboo activated carbon powder: bamboo chips and phosphoric acid solution are mixed and kneaded for 10-30min, wherein, the impregnation ratio of the bamboo chips and the phosphoric acid solution is 1:1.4; the particle size of the bamboo chips is 6 mesh, the water content of the bamboo chips is 12%; the concentration of the phosphoric acid solution is 50%; the kneaded material is directly contacted with the flue gas at 400°C for 3.5 hours in countercurrent, so that the material is carbonized and activated Finally, the activated material is obtained, and after the activated material ...

Embodiment 2

[0034] In Example 2, a lead-free PVC pipe is made of the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 5 parts of titanium dioxide, 10 parts of bamboo activated carbon powder, 7 parts of filler, 4 parts of lubricant, 3 parts of toughening agent.

[0035] The preparation method of above-mentioned lead-free PVC pipe material, comprises the steps:

[0036] (1) Preparation of bamboo activated carbon powder: bamboo chips and phosphoric acid solution are mixed and kneaded for 10-30min, wherein, the impregnation ratio of the bamboo chips and the phosphoric acid solution is 1:1.6; the particle size of the bamboo chips is 35 mesh, the water content of the bamboo chips is 20%; the concentration of the phosphoric acid solution is 55%; the kneaded material is directly contacted with the flue gas at 650°C for 4.5 hours in countercurrent, so that the material is carbonized and activated Finally, the activated material is obtained, and after the activated mate...

Embodiment 3

[0042] In this embodiment 3, a kind of lead-free PVC pipe material, described PVC pipe material is made of the raw material of following parts by weight: polyvinyl chloride 85 parts, titanium dioxide 2 parts, bamboo activated carbon powder 7 parts, filler 4 parts, 2.5 parts of lubricant, 1.5 parts of toughening agent.

[0043] The preparation method of above-mentioned lead-free PVC pipe material, comprises the steps:

[0044](1) Preparation of bamboo activated carbon powder: bamboo chips and phosphoric acid solution were mixed and kneaded for 20min, wherein the impregnation ratio of the bamboo chips to the phosphoric acid solution was 1:1.5; the particle size of the bamboo chips was 20.5 mesh , the water content of the bamboo chips is 16%; the concentration of the phosphoric acid solution is 52.5%; the kneaded material is directly contacted with the flue gas at 525° C. for 4 hours, so that the material is carbonized and activated to obtain activation material, the activated m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com