Vacuum heat treatment furnace with chemical oxygen-removing system

A vacuum heat treatment furnace and chemical deoxidization technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of long heating time, low heating speed, low radiation efficiency, etc., to reduce power consumption and mechanical wear, reduce heating The effect of time and heating rate is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

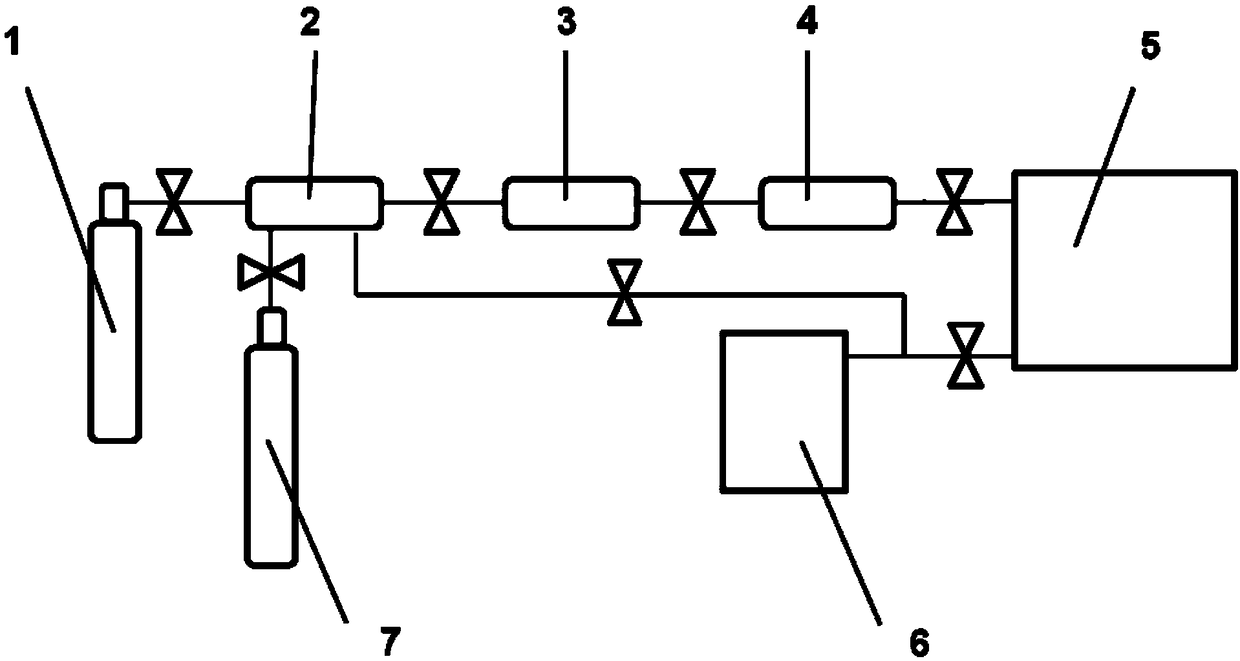

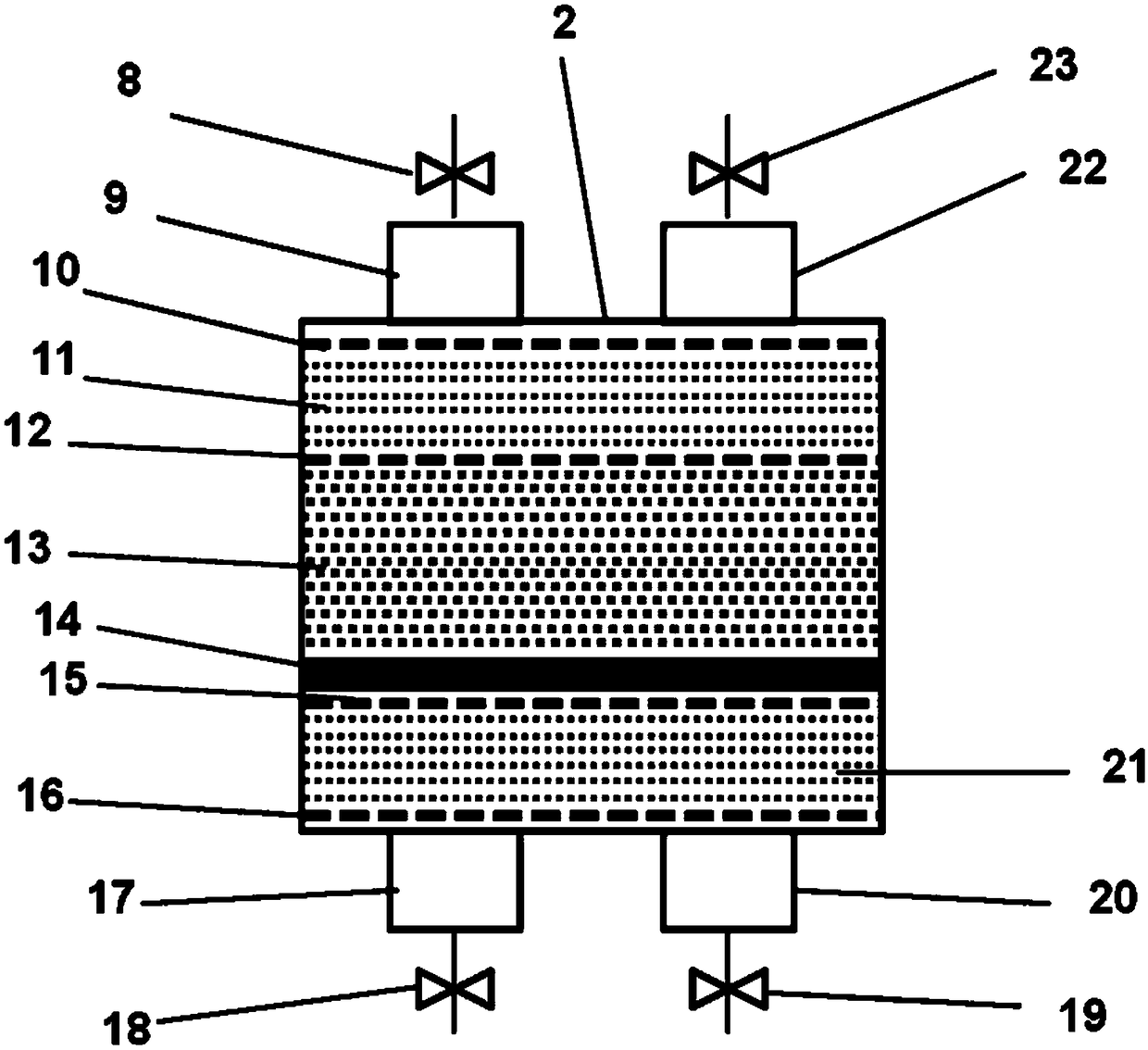

[0027] like Figure 1~2 As shown, a vacuum heat treatment furnace with a chemical deoxidation system includes a shielding gas cylinder 1, a vacuum furnace chamber 5 and a vacuum pump 6, the shielding gas cylinder 1 and the vacuum pump 6 are respectively connected to the vacuum furnace chamber 5, and the vacuum heat treatment furnace also includes Deoxygenation tank 2, one end of the deoxygenation tank 2 is connected to the protective gas source 1 through the protective gas inlet valve 18, and the other end is connected to the vacuum furnace chamber 5 through the protective gas outlet valve 23, and the deoxygenation tank 2 is equipped with a deoxygenation layer 13 and heater 14.

[0028] The vacuum heat treatment furnace also includes a reducing gas source 7, which is connected to one end of the oxygen removal tank 2 through a reducing gas inlet valve 19, and the other end of the oxygen removal tank 2 is connected to a vacuum pump 6 through a reducing gas outlet valve 8.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com