A kind of Pt-modified gradient Al coating and preparation method thereof

A gradient and modification technology, applied in coatings, metal material coating processes, and superimposed layer plating, etc., can solve the problems of lowering melting point and increasing brittleness of coatings, delaying degradation, improving service life, and achieving excellent resistance to corrosion. The effect of high temperature oxidation performance and hot corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

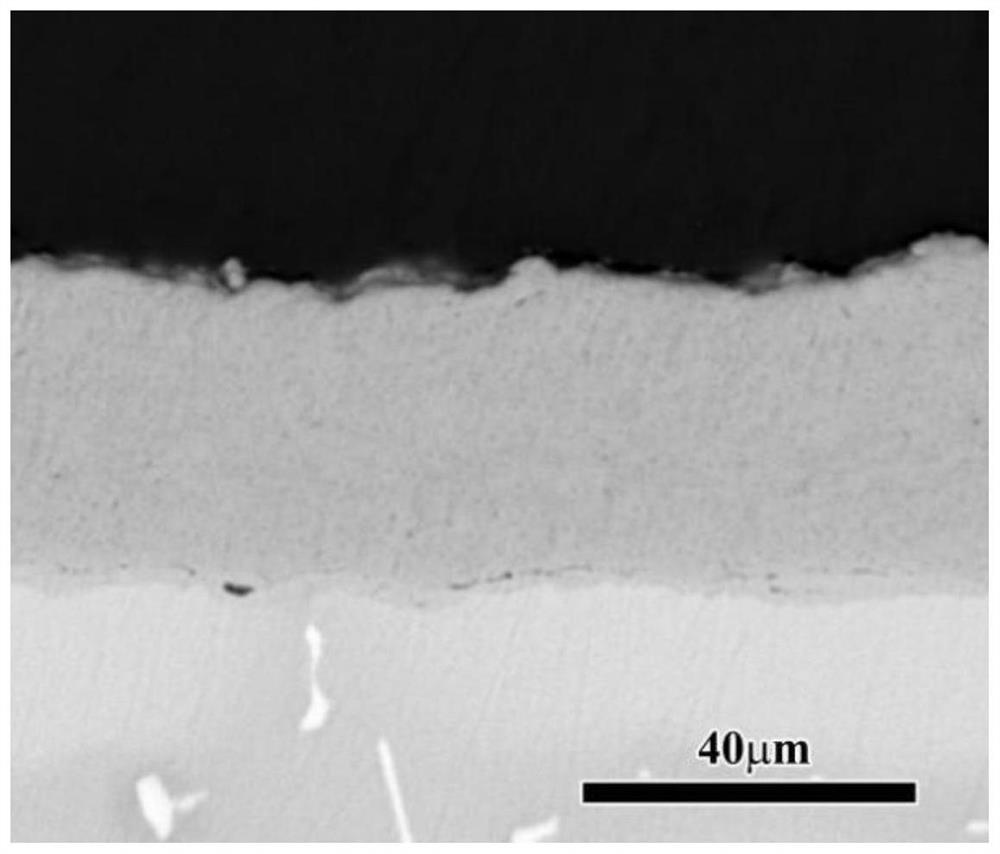

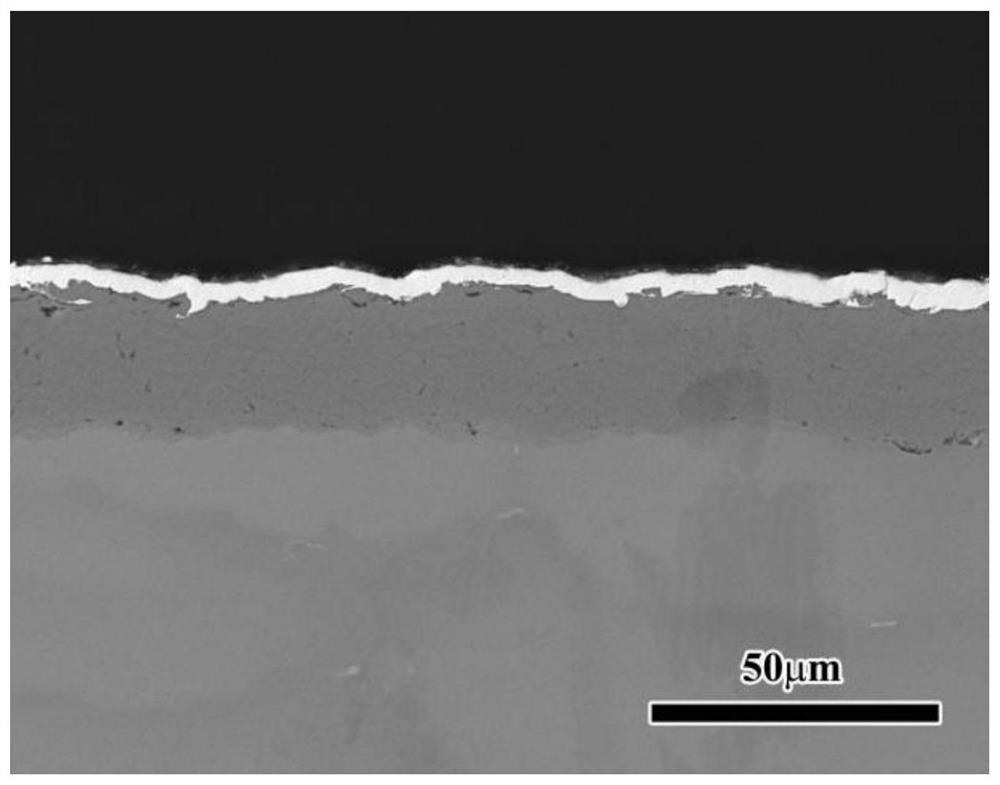

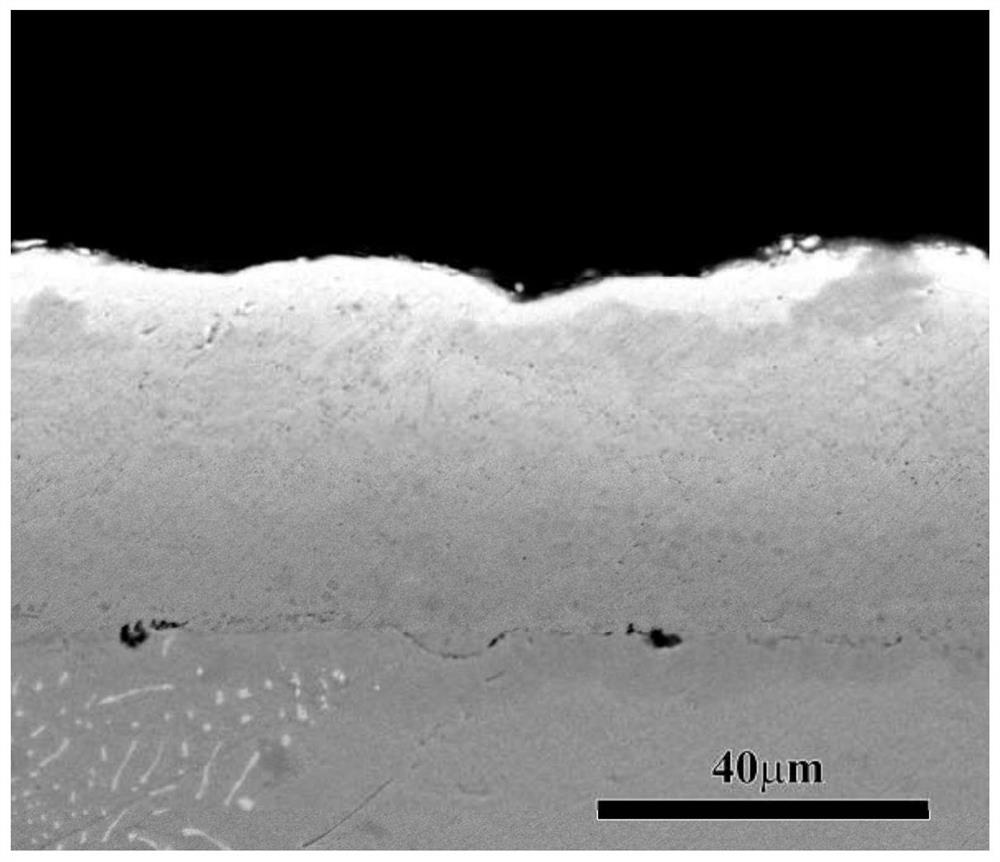

[0033] In this example, a Pt-modified gradient Al coating is prepared on a nickel-based superalloy. The composition of the nickel-based single-crystal superalloy used is (wt.%): Co 10.0%, Cr 8.0%, W 11.0%, Al 6.0 %, Ti 1.0%, Mo 1.0%, Nb 1.5%, C 0.05%, and the balance is Ni. The coating preparation process is as follows:

[0034] Firstly, the substrate was polished, sandblasted, and ultrasonicated in deionized water and acetone for 30 min successively. Rinse with alcohol and dry before use. When using arc ion plating to deposit MCrAlY coating, pre-evacuate to 7×10 -3 Pa, high-purity Ar gas was introduced during bombardment and deposition, and the vacuum degree was 2×10 -1 Pa. When the sample is pre-sputtered and bombarded to clean, the target base distance is 240mm, the pulse bias is -600V, the duty cycle is 33%, and the cleaning time is 5min; during deposition, the target base distance is 240mm, the arc voltage is 20V, and the arc current is 60~65A, pulse bias voltage is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com