Chrome-free passivating agent for hot galvanizing structural part and preparation method thereof

A technology of chromium-free passivation agent and structural parts, applied in the direction of metal material coating process, etc., can solve the problems such as the inability to obtain further breakthroughs in molybdate film thickness, easy wear of edges and corners, and limited application, etc. Strong shear force, strong adhesion, and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

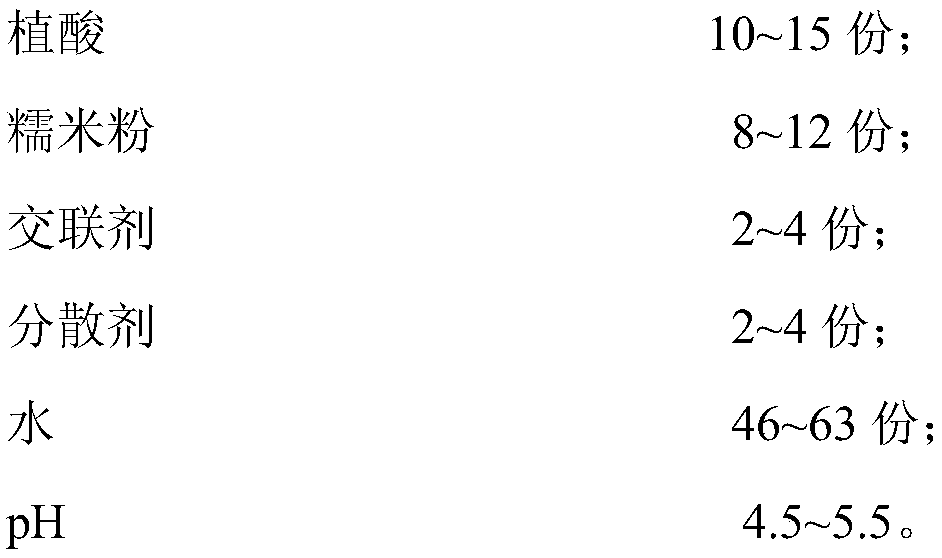

[0024] A chromium-free passivator for hot-dip galvanized structural parts, made of raw materials with the following weights:

[0025]

[0026] The preparation method specifically includes the following steps:

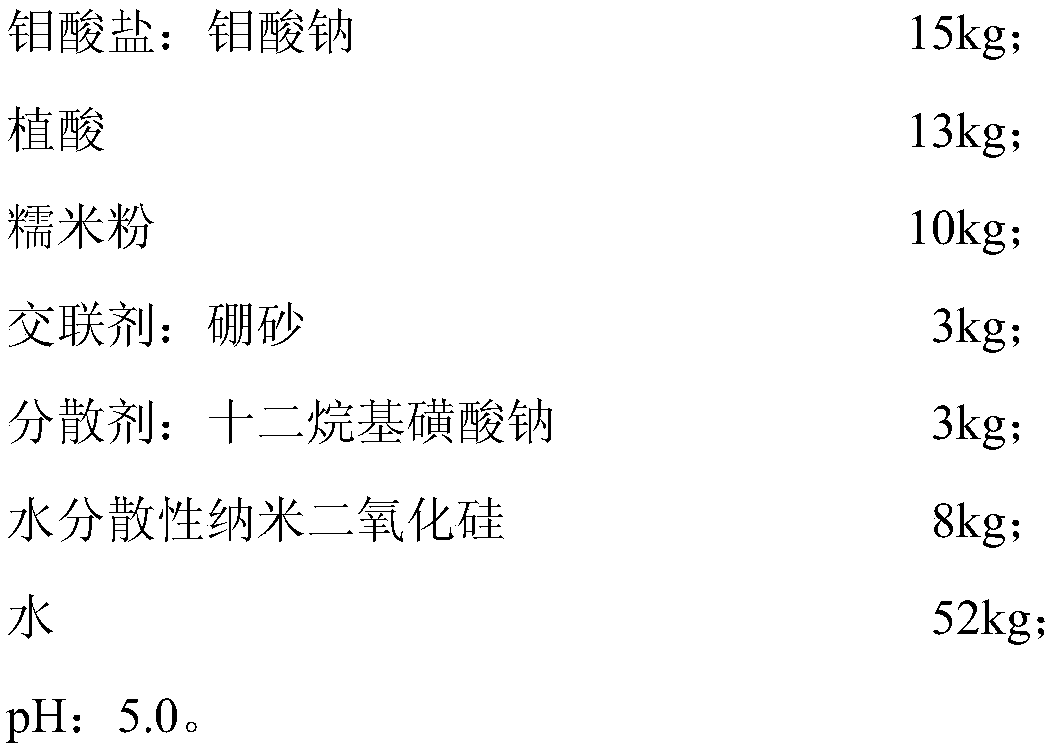

[0027] After passing the glutinous rice flour through a 200-mesh sieve, weigh the raw materials by weight. First add phytic acid, molybdate, and crosslinking agent to the water. After stirring, add the glutinous rice flour, raise the temperature to 65 degrees Celsius, and stir until dissolved. Add dispersant and water-dispersible nano silicon dioxide, then stir and disperse at 65 degrees Celsius until uniform, then adjust the pH to 5.0, and just cool.

[0028] The method of use is as follows: Dilute the above passivation agent and water at a ratio of 1:20 and put them into the passivation tank respectively, heat it to 30-40 degrees Celsius, and immerse the hot-dip galvanized structure directly into the passivation tank for 15 seconds. After taking it out, it can be dried with...

Embodiment 2

[0030] A chromium-free passivator for hot-dip galvanized structural parts, made of raw materials with the following weights:

[0031]

[0032] The preparation method: the same as in Example 1.

[0033] The method of use: the same as in Example 1.

Embodiment 3

[0035] A chromium-free passivator for hot-dip galvanized structural parts, made of raw materials with the following weights:

[0036]

[0037] The preparation method specifically includes the following steps:

[0038] The preparation method: the same as in Example 1.

[0039] The method of use: the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com