Cross-linked succinate oleracea gum and preparation method thereof

A technology of succinate and cyanine gum, which is applied in the field of preparation of cross-linked succinate succinate gum, can solve the problems of hydrophobic cross-linking and esterification of succinate gum, thermal stability of succulent gum, Creep and colloidal stability and other issues, to achieve the effects of easy industrial production, colloidal stability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the present invention includes adjusting milk, cross-linking, esterification, neutralization, filtration, ketone washing and drying. Specific steps are as follows:

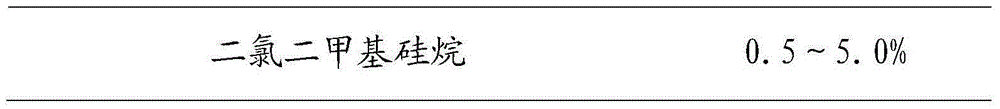

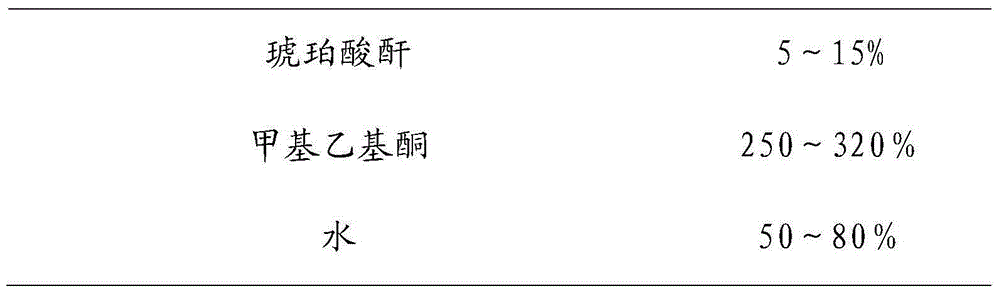

[0021] Take the raw materials according to the above ratio for later use, adjust the amount of squash gum with methyl ethyl ketone and water to make an emulsion with a mass percentage concentration of 20-25%, put it in a reaction kettle, stir, and heat up to 40-60°C , adjust the pH of the emulsion to 10.0-10.5 with an aqueous solution of sodium hydroxide methyl ethyl ketone (the mass ratio of methyl ethyl ketone to water is 8:2) with a concentration of 3-5% by mass, and slowly add Zhanjue Tian Cyanine glue quality 0.5~5% dichlorodimethylsilane, use the mass percent concentration in the reaction process to be 3~5% sodium hydroxide methyl ethyl ketone aqueous solution (the mass ratio of methyl ethyl ketone and water is 8: 2) Keep the pH of the emulsion constant. After reacting for 1...

Embodiment 1

[0023] Prepare 100kg of squash gum (absolutely dry) with methyl ethyl ketone and water to make an emulsion with a mass percentage concentration of 20% according to the formula, place it in a reaction kettle, stir, heat up to 40°C, and use a mass percentage concentration of 5% aqueous solution of sodium hydroxide methyl ethyl ketone (the mass ratio of methyl ethyl ketone to water is 8:2) to adjust the pH of the emulsion to 10.0, and slowly add dimethyl dichloride, which accounts for 0.5% of the mass of dry safflower gum In the reaction process, the pH of the emulsion was kept constant with 5% sodium hydroxide methyl ethyl ketone aqueous solution (the mass ratio of methyl ethyl ketone and water was 8:2) during the reaction. The concentration is 10% dilute hydrochloric acid to adjust the pH of the emulsion to 8.0, and then slowly add succinic anhydride accounting for 5% of the mass of absolute dry safflower gum, and then add 5% sodium hydroxide methyl ethyl ketone aqueous solution...

Embodiment 2

[0025] Prepare 100kg of squash gum (absolutely dry) with methyl ethyl ketone and water to make an emulsion with a mass percentage concentration of 22% according to the formula, place it in a reaction kettle, stir, heat up to 45°C, and use a mass percentage concentration of 4% aqueous solution of sodium hydroxide methyl ethyl ketone (the mass ratio of methyl ethyl ketone to water is 8:2) to adjust the pH of the emulsion to 10.3, and slowly add dimethyl dichloride, which accounts for 1.0% of the mass of the absolute dry squash gum In the reaction process, the pH of the emulsion was kept constant with 4% sodium hydroxide methyl ethyl ketone aqueous solution (the mass ratio of methyl ethyl ketone to water was 8:2) during the reaction. After 1.5 hours of reaction, use The pH of the emulsion was adjusted to 8.5 with dilute hydrochloric acid with a percentage concentration of 10%, and then slowly added succinic anhydride accounting for 8% of the mass of absolute dry safflower gum, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com