Silane-class chromium-free passivating agent and preparation method thereof

A chromium-free passivator and silane-based technology, applied in the coating process of metal materials, etc., can solve the problems of easy damage, no self-repair ability, thin passivation film, etc., to improve hydrophobicity, adhesion, and adhesion Efforts to enhance the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

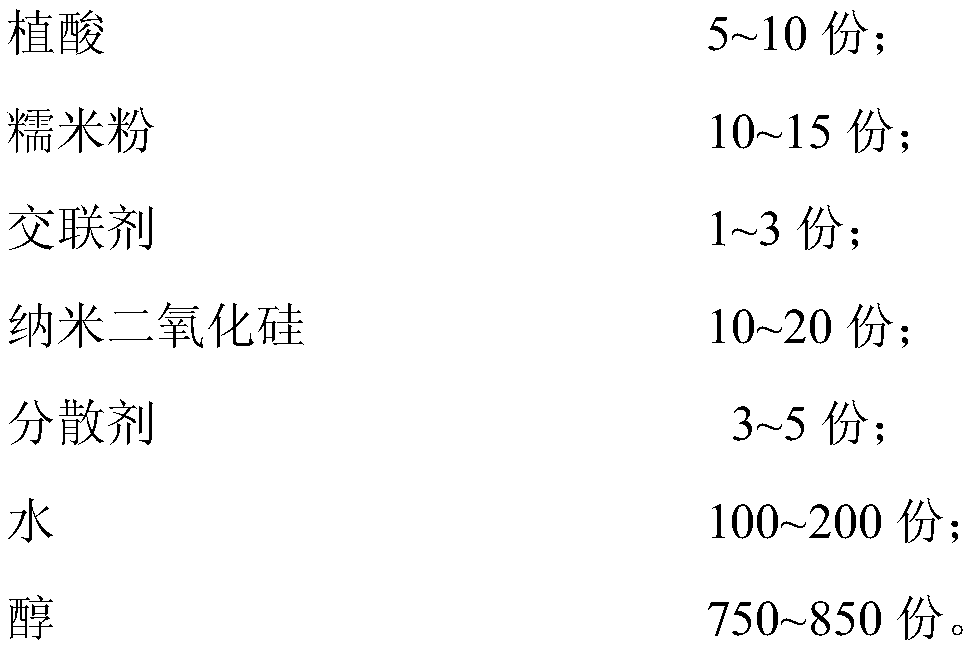

[0028] A chromium-free passivating agent for hot-dip galvanized structural parts, made of the following raw materials by weight:

[0029]

[0030]

[0031] Its preparation method specifically comprises the following steps:

[0032] After passing the glutinous rice flour through a 200-mesh sieve, weigh each raw material by weight, first mix the alcohol and water evenly, then add organosilane, corrosion inhibitor, phytic acid, and cross-linking agent to it in turn, stir until dissolved, and then stir Slowly add glutinous rice flour at a speed of 20mL / min, continue to stir for 30min, then add nano-silica and dispersant, stir and disperse until uniform.

[0033] The method of use is: after degreasing the galvanized structural parts, dilute the above passivating agent 4 times with water and then spray it on the surface. After the passivation time is 10 seconds, dry it with hot air at 60 degrees Celsius or dry it naturally.

Embodiment 2

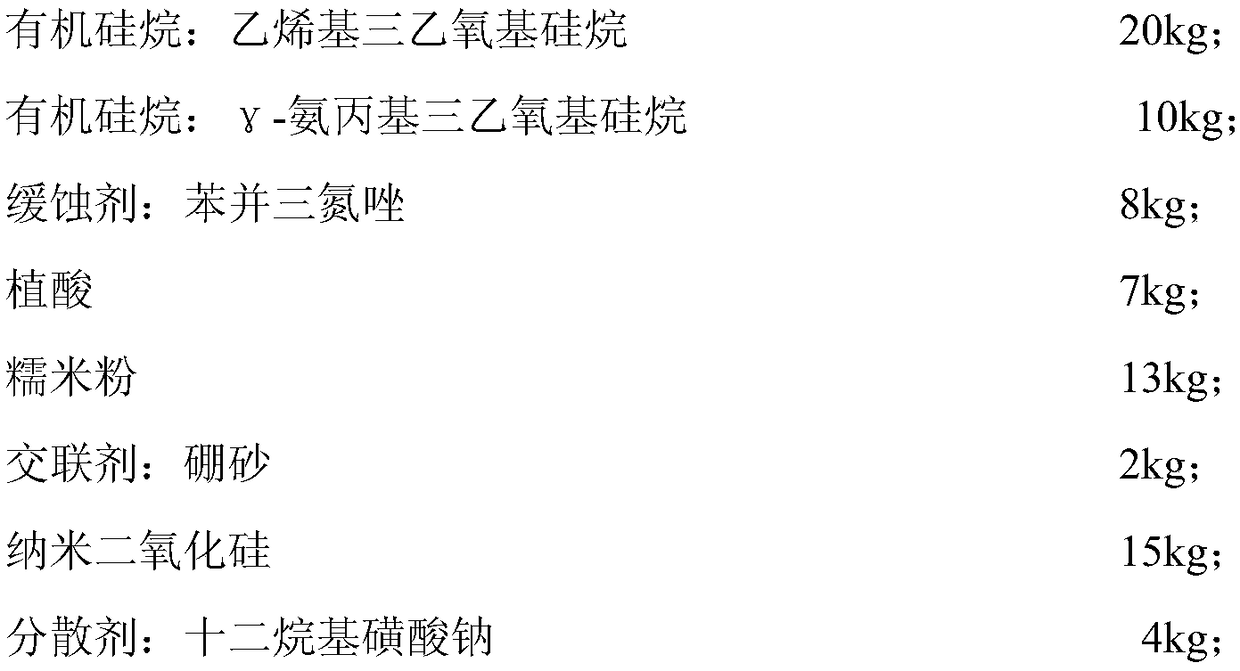

[0035] A chromium-free passivating agent for hot-dip galvanized structural parts, made of the following raw materials by weight:

[0036]

[0037] Its preparation method: with embodiment 1.

[0038] Its using method is: with embodiment 1.

Embodiment 3

[0040] A chromium-free passivating agent for hot-dip galvanized structural parts, made of the following raw materials by weight:

[0041]

[0042]

[0043] Its preparation method: with embodiment 1.

[0044] Its using method is: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com