Non-Post-Treated Bacteriostatic Blends

A technology of blends and mixtures, applied in fiber treatment, fiber mixing, yarn and other directions, can solve the problems of poor washing resistance, bacteria breeding, easy odor, etc., to balance cost and spinnability, Avoid the effects of complex multi-layered structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

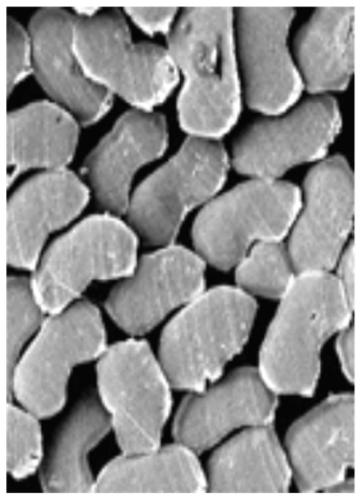

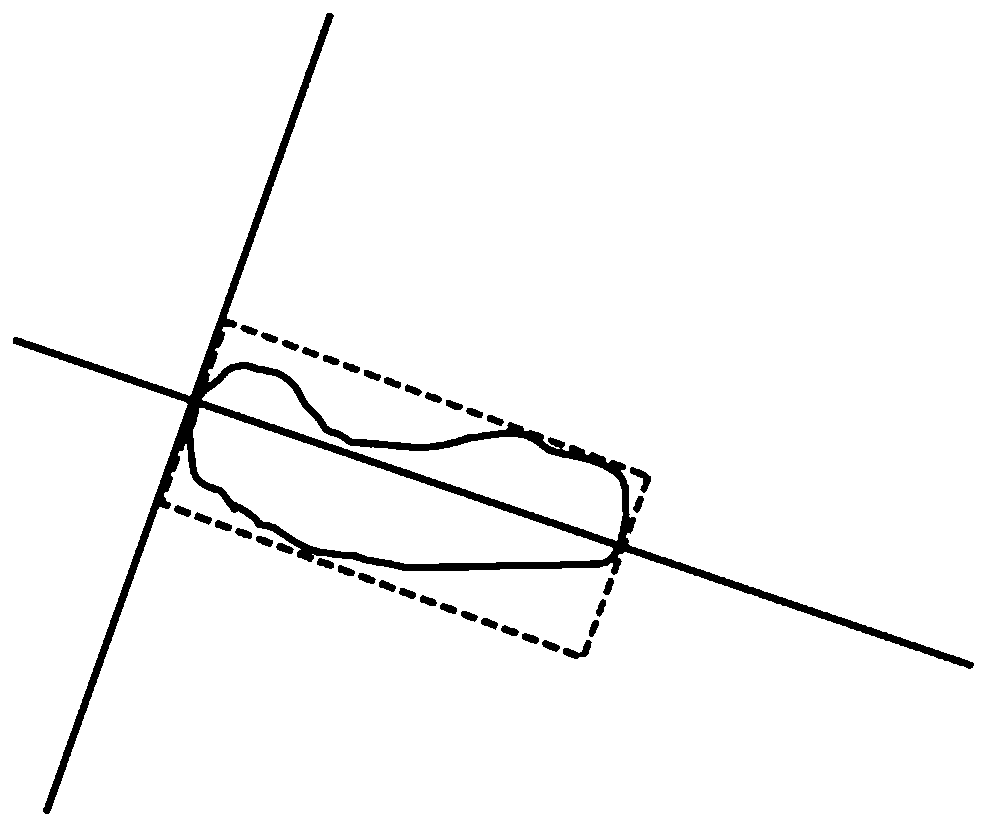

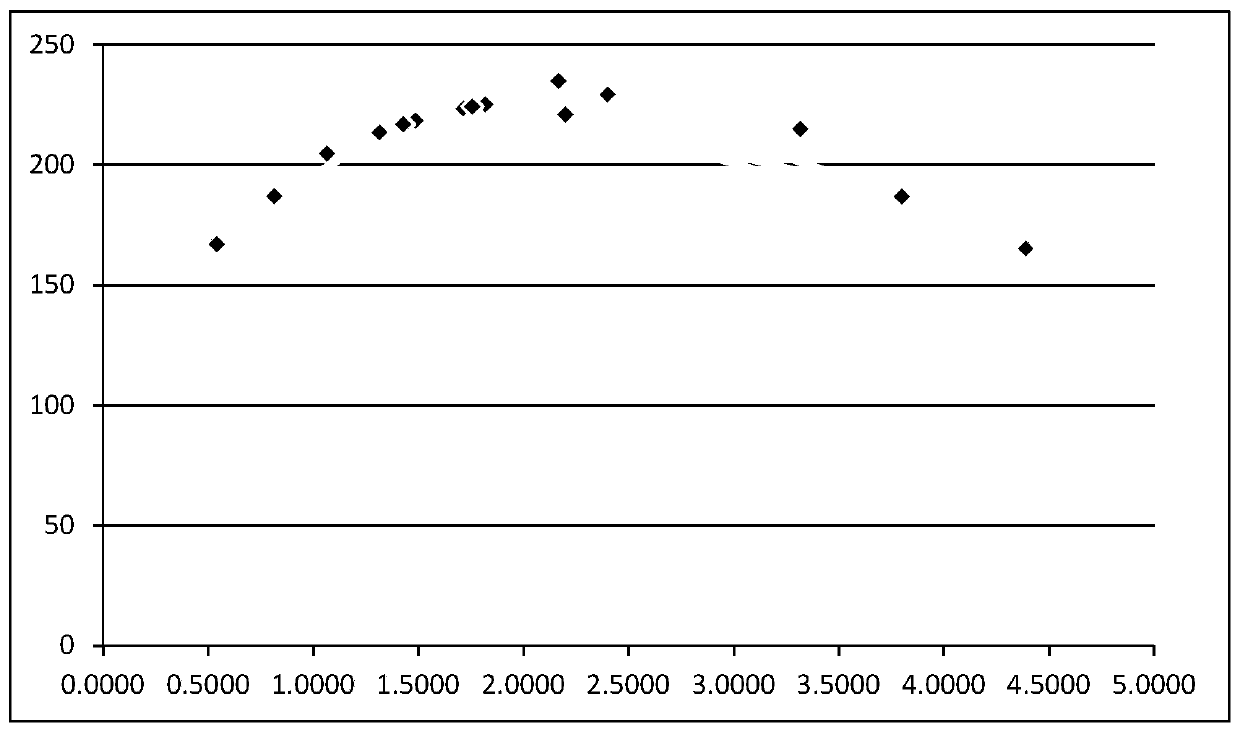

Image

Examples

Embodiment 18

[0078] Embodiment 18 winds on a slotted winder equipped with a capacitive yarn clearer, adopts an all-air knot, and winds it into a pagoda-shaped cheese for weaving.

Embodiment 19

[0079] Embodiment 19 winds on a slotted winder equipped with a capacitive yarn clearer, adopts an all-air knot, and winds it into a pagoda-shaped cheese for weaving.

[0080] Example 1, 3-4, 9-12, 16 are combined on the doubling machine equipped with photoelectric yarn clearer, two yarns and one yarn, set at the same tension, all using full air knots, flat tubes For package yarn, the nominal weight of the yarn is controlled within 1000 grams, and the deviation is within 1 gram.

[0081] Examples 2, 5, 7-8, 13-15 are combined on the yarn doubling machine equipped with photoelectric yarn clearer, two yarns are combined and one is set at the same tension, and all air knots are used, and flat tubes are used. For package yarn, the nominal weight of the yarn is controlled within 1000 grams, and the deviation is within 1 gram.

[0082] Embodiment 1, 3-4, 9-12, and 16 are twisted on a two-for-one twister, the twist rate is 87%, S twist, and are wound into pagoda-shaped cheese.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com