Anti-bacterial and moisture absorption quick-drying finishing method of cotton fabric based on electron beam irradiation technology

A technology of electron beam irradiation, moisture absorption and quick drying, applied in physical treatment, fiber treatment, plant fiber and other directions, can solve the problems of material consumption, time consumption, labor consumption, etc., to improve durability, simple operation, and cotton fiber damage degree. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

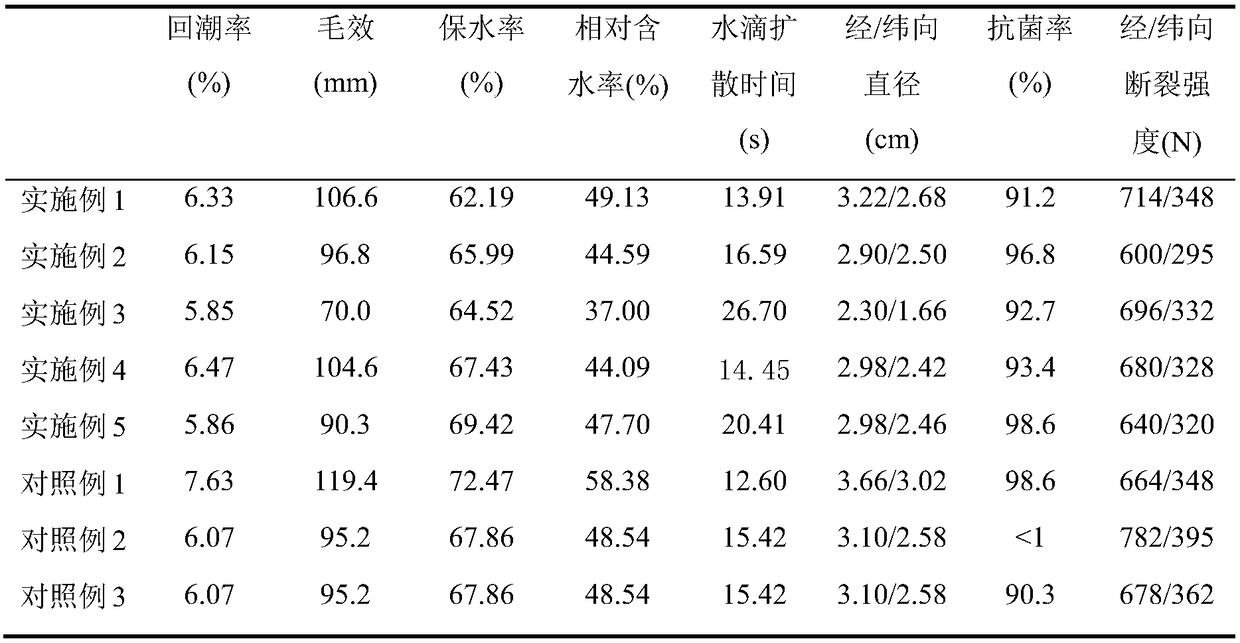

Examples

Embodiment 1

[0036] Fabric: pure cotton fabric (40 S ×40 S / 133*72)

[0037] (1) Electron beam irradiation finishing: antibacterial agent SQ-5700 (amount is 5% relative to the fabric quality)

[0038] The fabric is soaked for 3 hours→rolled (residue rate is 80%)→electron beam irradiation (irradiation dose 65kGy).

[0039] (2) Low surface energy finishing: Hexyldimethoxysilane (amount of 1% relative to the fabric quality)

[0040] Hydrolysis at 20°C for 6h (solvent methanol, pH value 2, bath ratio 1:10) → impregnation for 0.5h rolling (residue rate 80%) → drying at 80°C for 20min.

Embodiment 2

[0042] Fabric: pure cotton fabric (40 S ×40 S / 133*72)

[0043] (1) Electron beam irradiation finishing: antibacterial agent DC-5700 (amount is 15% relative to the fabric quality)

[0044] Soaking for 9h→rolling (reduction rate of 90%)→electron beam irradiation (irradiation dose 65kGy).

[0045] (2) Low surface energy finishing: decyltrimethoxysilane and dodecyldiethoxysilane (amount of 5% relative to the quality of the fabric)

[0046] Hydrolysis at 80°C for 0.5h (solvent propanol, pH value 6, bath ratio 1:40) → impregnation for 4h rolling (residue rate 150%) → drying at 100°C for 10min.

Embodiment 3

[0048] Fabric: pure cotton fabric (40 S ×40 S / 133*72)

[0049] (1) Electron beam irradiation finishing: antibacterial agent HM98-2 (amount is 15% relative to the fabric quality)

[0050] Soak for 6h→rolling (rolling ratio 150%)→electron beam irradiation (irradiation dose 22kGy).

[0051] (2) Low surface energy finishing: low surface energy modifier dodecyldiethoxysilane (amount of 2% relative to the quality of the fabric)

[0052] Hydrolysis at 40°C for 1h (solvent ethanol, pH value 4, bath ratio 1:20) → impregnation for 1h rolling (residue rate 90%) → drying at 110°C for 5min. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com