A single-side spraying conductive film and a preparation method thereof

A conductive film, single-sided technology, applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, device for coating liquid on the surface, etc., can solve problems such as easy falling off of metal layer jelly and poor adhesion , achieve low cost, increase adsorption effect, and good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

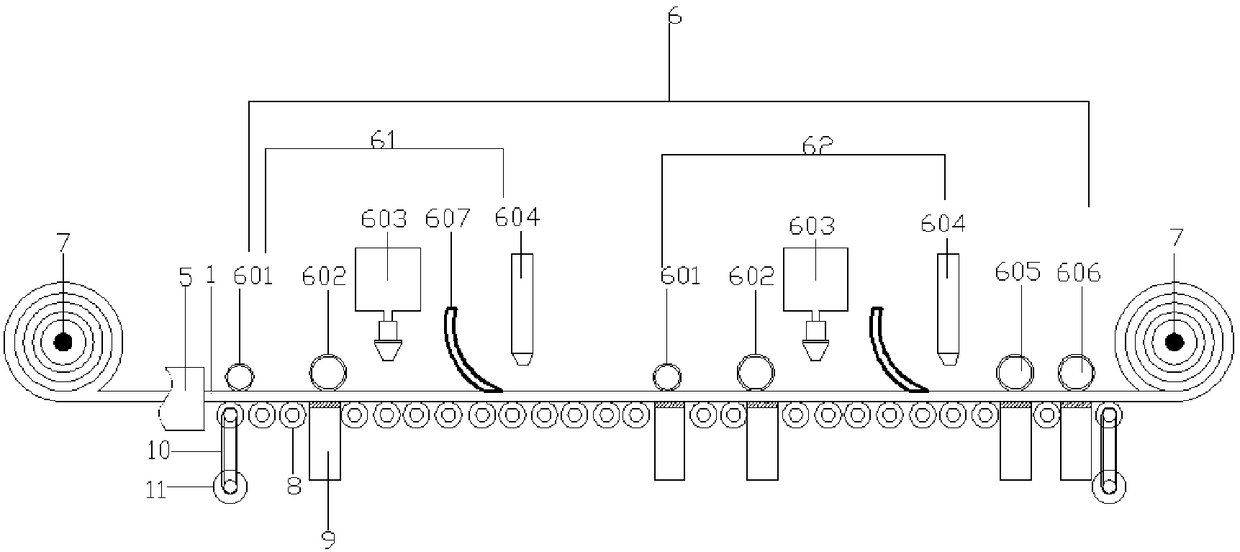

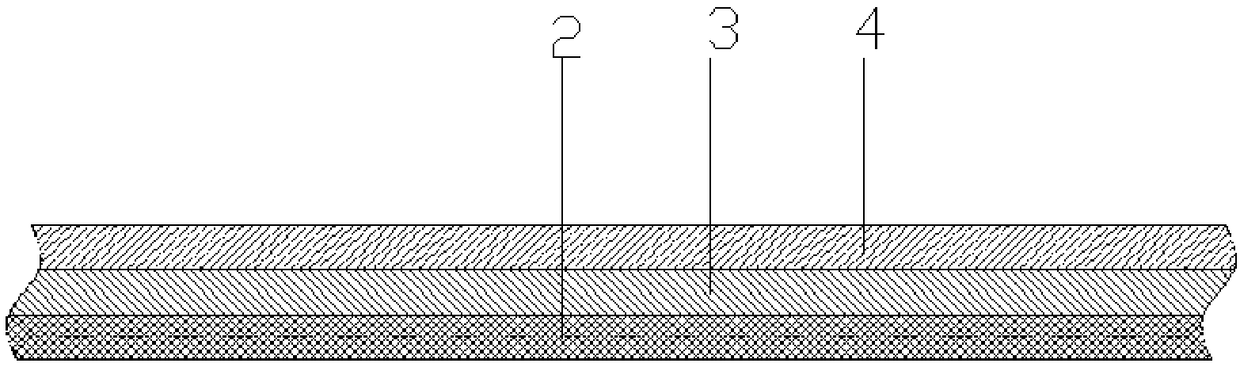

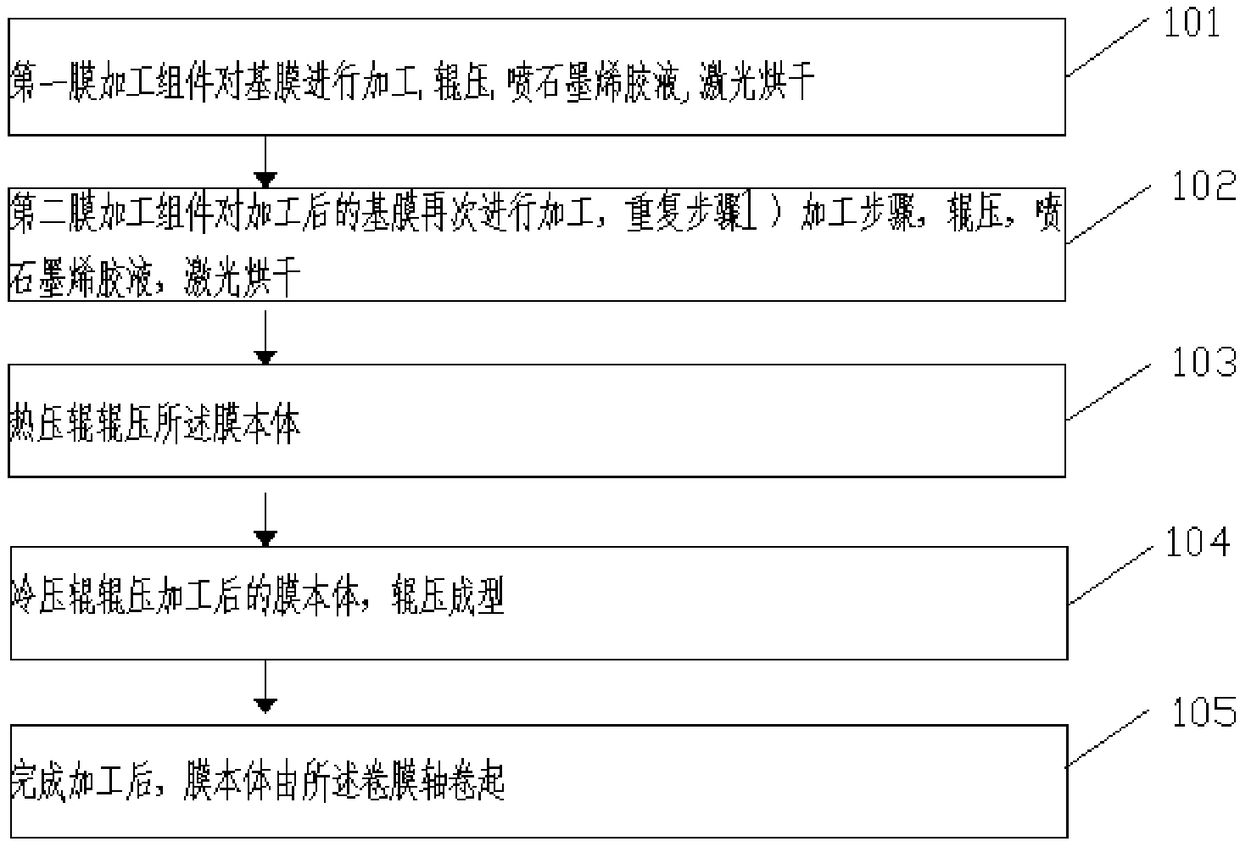

[0038] refer to Figure 1 to Figure 3 As shown, a single-sided spray-coated conductive film and a preparation method thereof include a film body 1, and the film body 1 includes a base film 2, a graphene layer 3 positioned on one side of the base film 2, and a graphene layer positioned on one side of the graphene layer 3. The sealing layer 4 of the film body 1 is made by the following device: including a film outlet 5, a film processing device 6, a film roll shaft 7, and a number of rolls connected to the film processing device 6 below the film processing device 6 Roller 8, the film outlet 5 is arranged on one end of the film processing device 6 and is connected with the roll film shaft 7 of the base film 2, and the film roll shaft 7 is set on the other end of the film processing device 6 for making the finished film The film body 1 is rolled up, the base film 2 is located above the roller 8, one end of the roller 8 is connected to the film outlet 5, and the other end is conne...

specific Embodiment

[0053] In actual use, the base film 2 passes through the film outlet 5, and the smooth guide film roller 601 in the first film processing assembly 61 rolls the base film 2, compacts the base film 2, and the rough rolling roller 602 rolls The base film 2 is roughened to increase the adsorption effect. The graphene nozzle 603 sprays the graphene glue, and the smoothing scraper 607 behind the graphene nozzle group 603 ensures that the sprayed graphene glue is uniform in thickness, and the ultraviolet laser emitter 604 emits Laser to dry the sprayed graphene glue;

[0054] The second film processing assembly 62 processes the processed base film 2 again, repeats the above processing steps, continues rolling, spraying graphene glue, laser drying, and further compacting to increase the adhesion effect of graphene glue, so that Graphene glue is not easy to fall off;

[0055] The hot pressing roller 605 rolls the film main body 1 , and the cold pressing roll 606 rolls the processed fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com