Core-shell heterostructure self-supporting electrode material, preparation method and application

A self-supporting electrode and heterostructure technology, applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of low specific capacity of supercapacitor electrode materials, and achieve excellent electrochemical performance and small charge transfer resistance. , the effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] On the other hand, an embodiment of the present invention also provides a method for preparing the above-mentioned self-supporting electrode material, comprising the following steps:

[0046] S1, nickel foam cleaning

[0047] S2, prepare P-Ni(OH) 2 / NF: Put the cleaned nickel foam into 30mL containing NaH 2 PO 4 H 2 o 2 In the high-pressure reactor of the solution, hydrothermally react at a certain temperature for a period of time; after the reactor is naturally cooled to room temperature, the product is washed several times with deionized water and ethanol respectively, and vacuum-dried at 50-70°C for 12-36h. Set aside after cooling;

[0048] S3, prepare P-Ni(OH) 2 @Ni-Co LDH: Weigh a certain amount of P-Ni(OH) 2 / NF, with Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O of H 2 o 2 The mixed solution (15wt%) is mixed and reacted in a reactor, and the hydrothermal reaction is performed for a certain period of time. After the reactor is cooled to room temperatu...

Embodiment 1

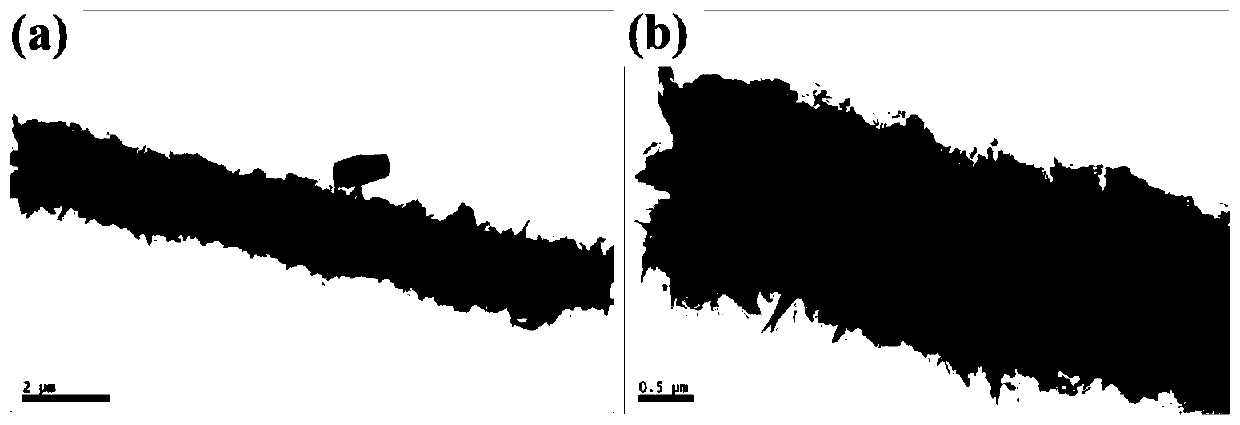

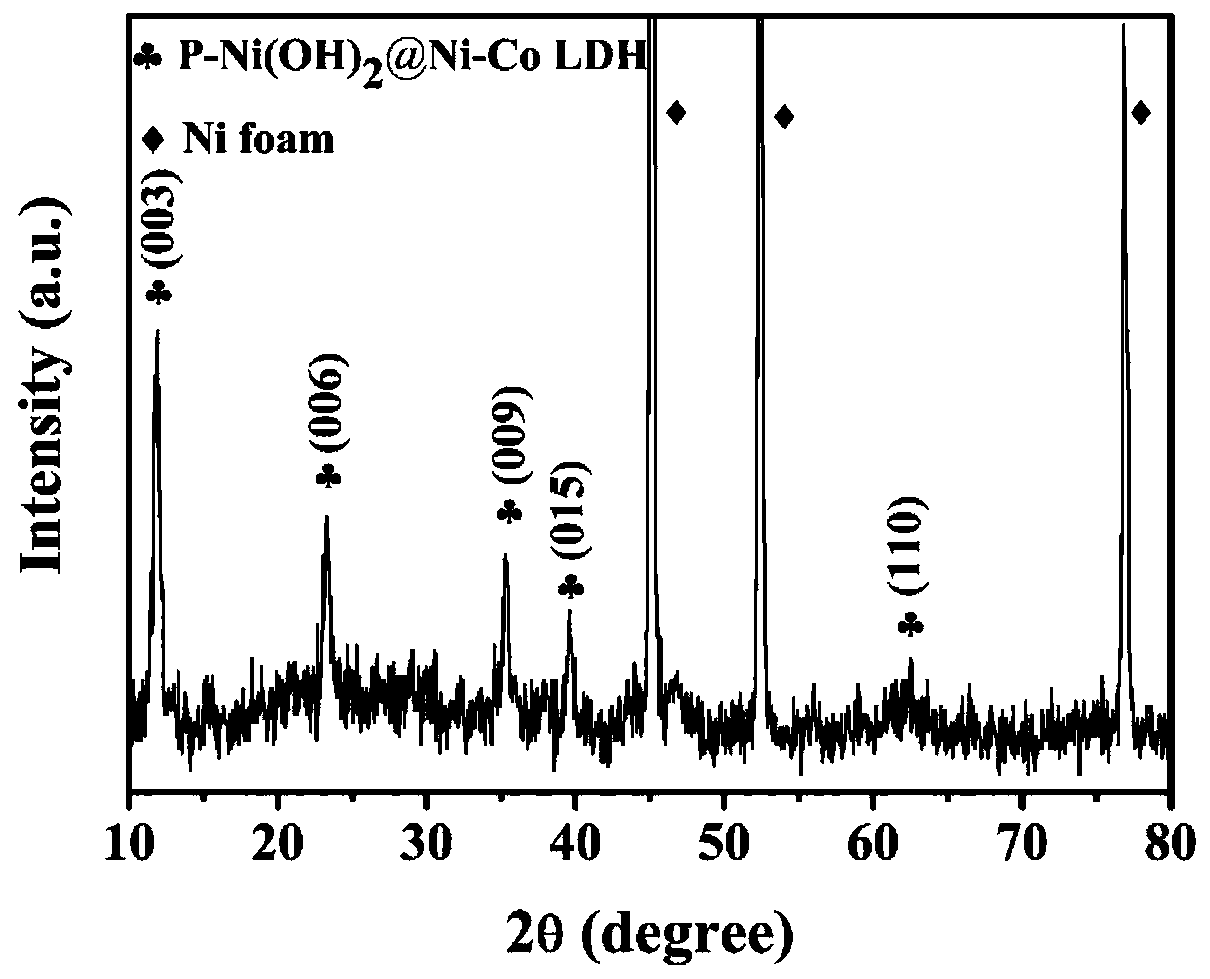

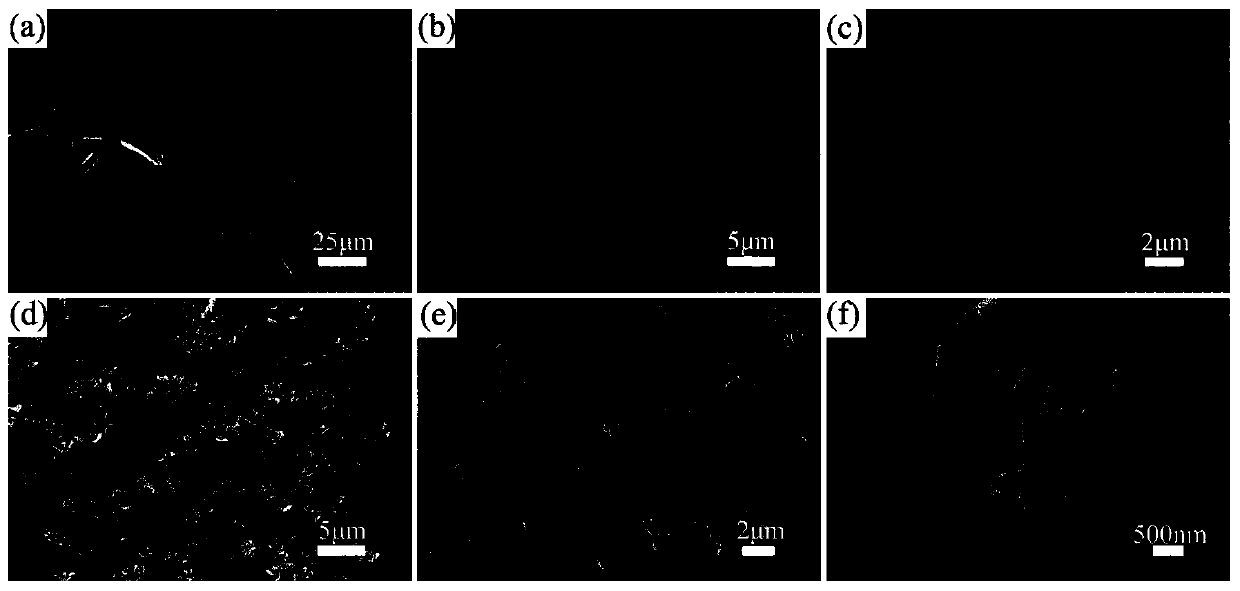

[0062] (1)P-Ni(OH) 2 / NF sample preparation: first put nickel foam (1cm×3cm) into acetone, hydrochloric acid (3M), absolute ethanol and deionized water, respectively, and ultrasonicate each for 5min to remove oxides and impurities on the surface; then Vacuum dried at 50°C for 48h. Then put the cleaned nickel foam (1cm×3cm) into 30mL containing 2mM NaH 2 PO 4 H 2 o 2 solution (15wt%) in an autoclave for 48 hours at 120°C; after the autoclave was naturally cooled to room temperature, the product was taken out and washed several times with deionized water and ethanol, and dried in vacuum at 50°C for 36 hours , that is, hexagonal prism-shaped P-Ni(OH) grown on nickel foam in situ 2 Micro / nanorod samples.

[0063] (2)P-Ni(OH) 2 Preparation of @Ni-Co LDH / NF samples: P-Ni(OH) 2 / NF samples were placed in a container containing 0.3mMNi(NO 3 ) 2 ·6H 2 O, 5mM Co(NO 3 ) 2 ·6H 2 30 mL of H in O 2 o 2 solution (15wt%) in a reactor, hydrothermally reacted at 150°C for 36h, a...

Embodiment 2

[0065] (1)P-Ni(OH) 2 / NF sample preparation: first put nickel foam (1cm×3cm) into acetone, hydrochloric acid (3M), absolute ethanol and deionized water respectively, and ultrasonicate each for 30min in order to remove oxides and impurities on the surface; then Vacuum dry at 70°C for 12h. Then put the cleaned foam nickel (1cm×3cm) into 30mL containing 50mMNaH2 PO 4 H 2 o 2 solution (15wt%) in an autoclave for 10 h at 220°C; after the autoclave was naturally cooled to room temperature, the product was taken out and washed several times with deionized water and ethanol, and dried in vacuum at 70°C for 12 h , that is, hexagonal prism-shaped P-Ni(OH) grown on nickel foam in situ 2 Micro / nanorod samples.

[0066] (2)P-Ni(OH) 2 Preparation of @Ni-Co LDH / NF samples: P-Ni(OH) 2 / NF samples were placed in a container containing 5mM Ni(NO 3 ) 2 ·6H 2 O, 0.5mM Co(NO 3 ) 2 ·6H 2 30 mL of H in O 2 o 2 solution (15wt%) in a reaction kettle, hydrothermally reacted at 170°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com