Hybrid film of quantum dots and polymer crosslinking and its preparation method and qled

A technology of quantum dots and polymers, which is applied in the fields of organic semiconductor device materials, semiconductor/solid-state device manufacturing, organic light-emitting device manufacturing/processing, etc. It can solve the problems of chemical cross-linking, large amounts of impurities, etc., and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

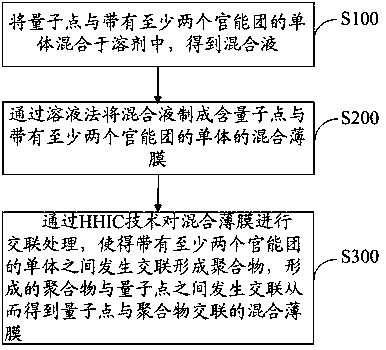

Method used

Image

Examples

Embodiment

[0055] 20mg QD with 50mgCH 2 OH-(CH 2 ) 3 -COOH was mixed into 1 ml of chlorobenzene solvent to obtain a mixed solution. Spin coat the mixed solution to form a layer containing QD and CH 2 OH-(CH 2 ) 3 -COOH mixed film, vacuum drying after film formation to evaporate the solvent, forming a 50nm QD and CH 2 OH-(CH 2 ) 3 -Hybrid thin films of COOH. The said containing QD and CH 2 OH-(CH 2 ) 3 The mixed film of -COOH is placed in the HHIC reactor, and H 2 , and make H 2 Transform into H plasma, adjust the H plasma energy to 10eV, and cross-link for 10 minutes to obtain a mixed film of QDs and polymers. In the cross-linking process of HHIC in this example, there is no H 2 O generation, while cross-linked by traditional chemical methods, H 2 O is a by-product of the condensation reaction.

[0056] To sum up, the present invention provides a cross-linked hybrid film of quantum dots and polymers, a preparation method and a QLED device. The present invention utilizes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com