Application of high-pressure and freezing wall breaking method in production process of preparing wall-broken ganoderma lucidum spore powder

A broken ganoderma lucidum spore powder and production process technology, applied in the direction of microorganism dissolution, microorganisms, methods based on microorganisms, etc., can solve the problems of large energy consumption, large investment, and large investment in mechanical equipment in physical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

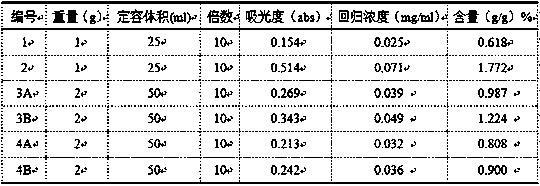

[0006] Take unbroken Ganoderma lucidum spore powder and divide it into two experimental groups, 40 grams in each group. No. 1 is the unbroken Ganoderma lucidum spore powder as a control, and No. 2 unbroken Ganoderma lucidum spore powder is added with 65ml of purified water and put into a pressure cooker under high pressure. Heating up to 121°C in 25 minutes, keeping at 121°C for 30 minutes, cooling down to 65°C in 2.5 hours, taking it out, drying in a 65°C oven for 4 hours, then storing in a 4°C refrigerator for 12 hours, taking it out Crush it with a spoon, dry it at 65°C for 6 hours, weigh it, and get it.

[0007] See Table 1 for the weight change of samples dried under high pressure.

[0008] Table 1 Dry weight change of Ganoderma lucidum spore powder after high pressure

[0009]

[0010] Note: No. 1 is the control of Ganoderma lucidum spore dry powder without water; No. 2 is the control of Ganoderma lucidum spore powder with water.

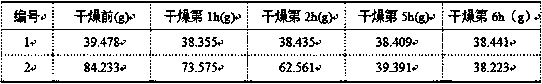

[0011] See Table 2 for the dry wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com