Preparation method of quartz lead

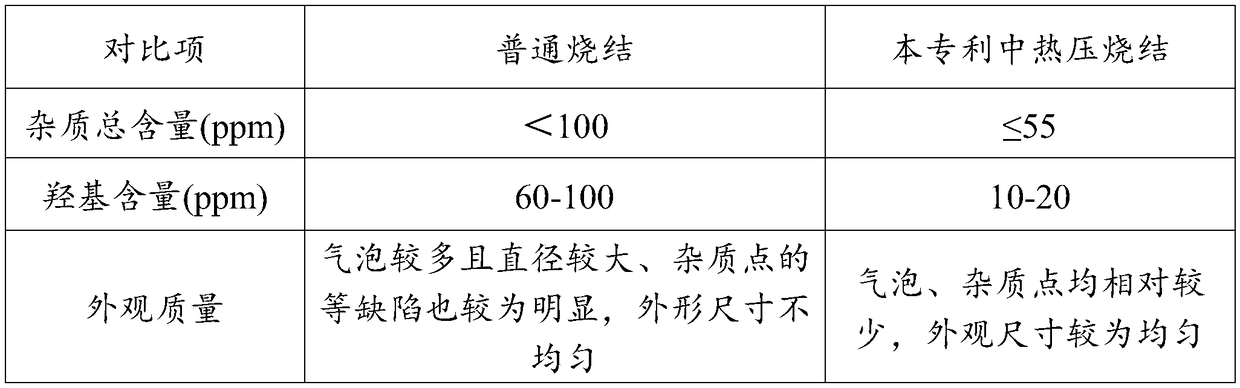

A technology of quartz ingot and quartz sand, which is applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of endangering the health of employees, increasing the amount of material burning loss, environmental dust pollution, etc., and achieves regular shapes and specifications, Reduce labor intensity and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

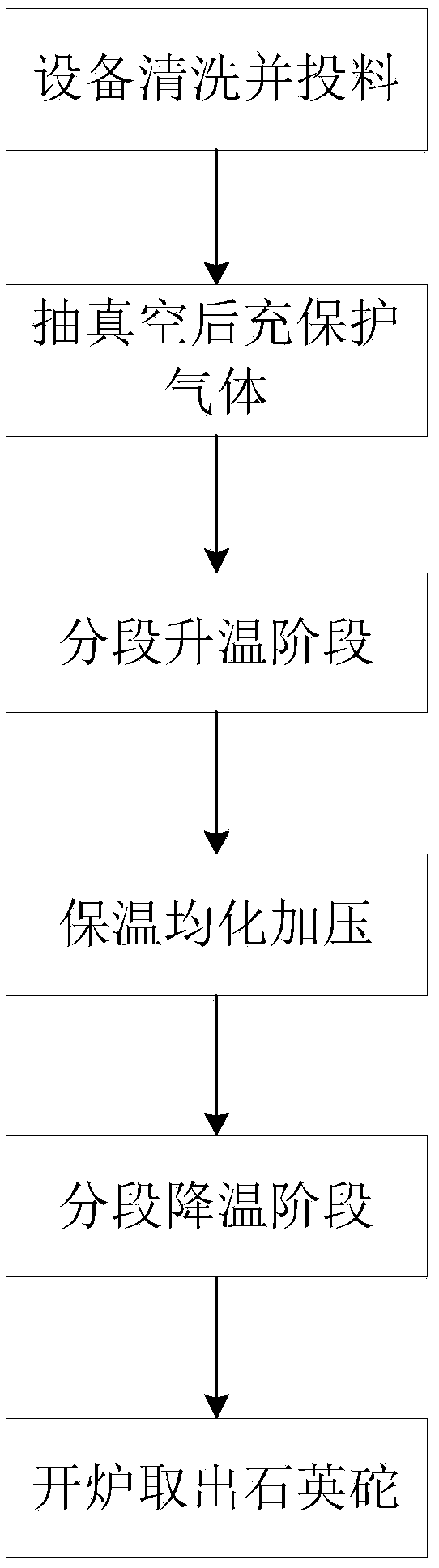

Method used

Image

Examples

Embodiment 1

[0037] Prepare a quartz ingot with a diameter of 300mm and a height of 400mm. Considering the amount of burning loss, throw 64-66Kg of quartz sand into the cleaned furnace, seal and vacuumize to 6×10 -3 Pa~8×10 -5 Pa, then fill the protective gas nitrogen or argon, make the pressure in the furnace lower than -0.05MPa, start heating the furnace, from room temperature to 1000°C-1300°C, keep warm for 2-3 hours (the best holding time is 3 hours ), continue to heat up to 1500°C-1550°C, keep warm for 2-3 hours (in order to remove the gas, the holding time is 3 hours), then raise the temperature to 2100°C-2300°C and keep warm for 10-20 hours (the best holding time is 12h ), to ensure that the quartz sand in the furnace is completely melted. After complete melting, cool down to 1700-2000°C at a rate of 50-100°C / h, pressurize mechanically at 10MPa for 3-8 hours, then cool down to 950-1200°C at 30-60°C / h and keep warm for 1-3 hours , Under dry protective gas conditions, it can be anne...

Embodiment 2

[0040] Prepare a quartz ingot with a diameter of 300mm and a height of 400mm. Considering the amount of burning loss, throw 64-66Kg of quartz sand into the cleaned furnace, seal and vacuumize to 6×10 -3 Pa~8×10 -5 Pa, then fill the protective gas nitrogen or argon, make the pressure in the furnace lower than -0.05MPa, start heating the furnace, from room temperature to 1000°C-1300°C, keep warm for 2-3 hours (the best holding time is 3 hours ), continue to heat up to 1500°C-1550°C, keep warm for 2-3 hours (in order to remove the gas, the holding time is 3 hours), then raise the temperature to 2100°C-2300°C and keep warm for 10-20 hours (the best holding time is 12h ), to ensure that the quartz sand in the furnace is completely melted. After complete melting, cool down to 1700-2000°C at a rate of 50-100°C / h, pressurize at 15MPa for 3-8 hours, then cool down to 950-1200°C at 30-60°C / h and keep warm for 1-3 Hours, under the condition of dry protective gas, it can anneal and remo...

Embodiment 3

[0043] Prepare a quartz ingot with a diameter of 300mm and a height of 400mm. Considering the amount of burning loss, throw 64-66Kg of quartz sand into the cleaned furnace, seal and vacuumize to 6×10 -3 Pa~8×10 -5Pa, then fill the protective gas nitrogen or argon, make the pressure in the furnace lower than -0.05MPa, start heating the furnace, from room temperature to 1000°C-1300°C, keep warm for 2-3 hours (the best holding time is 3 hours ), continue to heat up to 1500°C-1550°C, keep warm for 2-3 hours (in order to remove the gas, the holding time is 3 hours), then raise the temperature to 2100°C-2300°C and keep warm for 10-20 hours (the best holding time is 12h ), to ensure that the quartz sand in the furnace is completely melted. After complete melting, cool down to 1700-2000°C at a rate of 50-100°C / h, pressurize at 25MPa for 3-8 hours, then cool down to 950-1200°C at 30-60°C / h and keep warm for 1-3 Hours (temperature controlled at 1030°C), annealing under dry protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com