A whispering gallery microsphere cavity single-molecule gas sensor embedded in graphene

A gas sensor and microsphere cavity technology, applied in the field of sensing, can solve the problems of weak anti-electromagnetic interference, low sensing sensitivity, dependence on chemical reactions, etc., to improve the sensing response speed and sensitivity, and reduce the mode volume. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

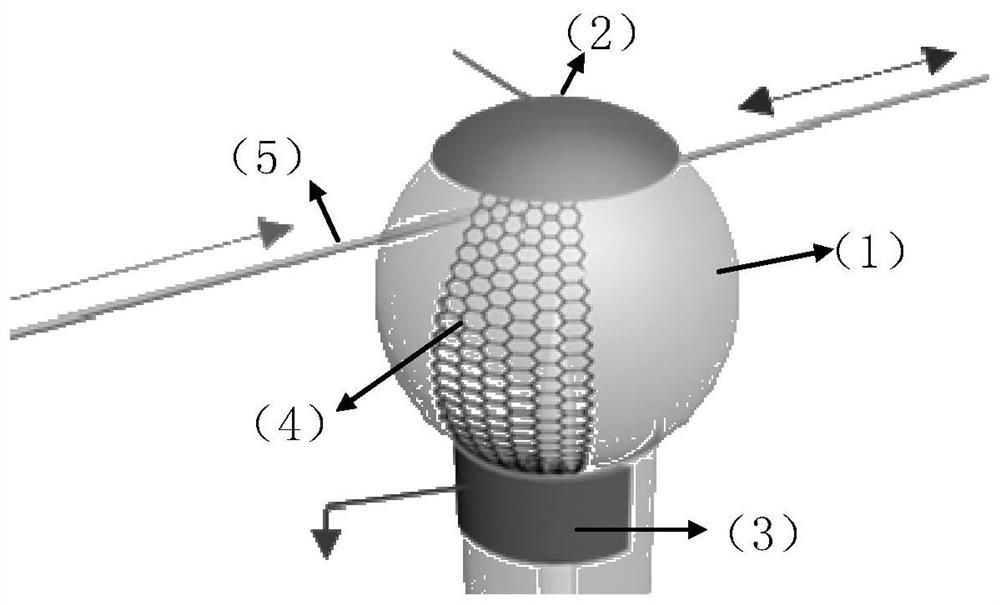

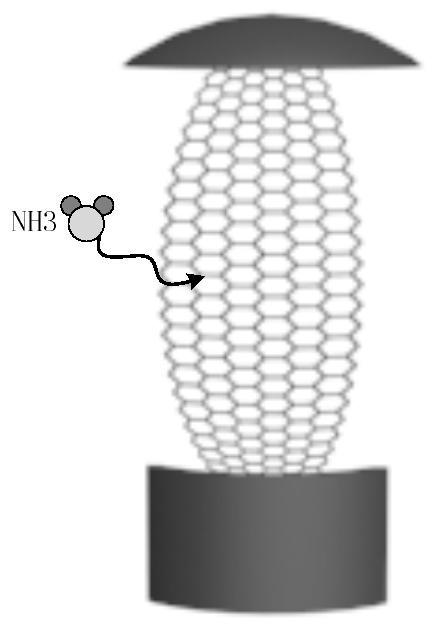

[0026] A graphene-embedded whispering gallery microsphere cavity single-molecule gas sensor, based on graphene singularity, is composed of micro-nano optical fiber, single-layer graphene and silica microspheres.

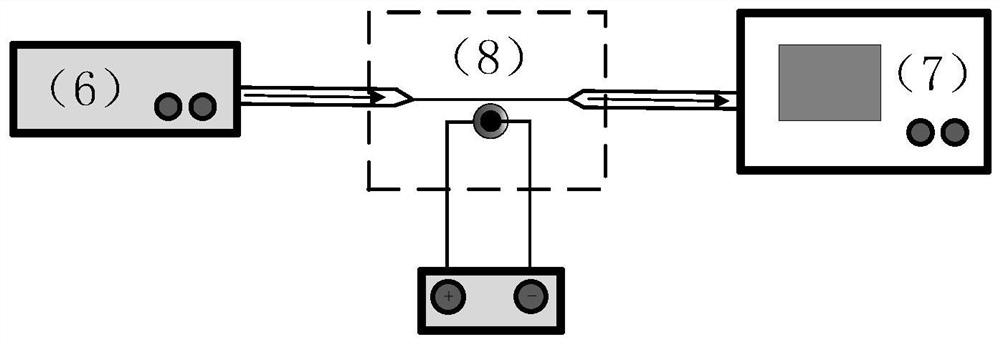

[0027] The micro-nano optical fiber is 4 cm long and 2 microns in diameter; the microsphere is 280 microns in diameter, coated with two gold electrodes with a thickness of 30 nanometers, and the distance between the two gold electrodes is 100 microns. A single-layer graphene film with a width of 80 microns and a thickness of 0.38 nm, the entire device is connected to the optical system through a single-mode fiber ( image 3 ). The micro-nano fiber achieves efficient coupling with the microsphere cavity, and the coupling efficiency is as high as 95%.

[0028] The resonant cavity enters the degenerate singularity by applying an exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com