A novel PFC inductor and a manufacturing method thereof

A new type of inductor technology, applied in the field of inductors, can solve the problems of large volume, large distributed capacitance, and inconvenient production of PFC inductors, and achieve the effects of increasing heat dissipation, reducing distributed capacitance, and improving power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

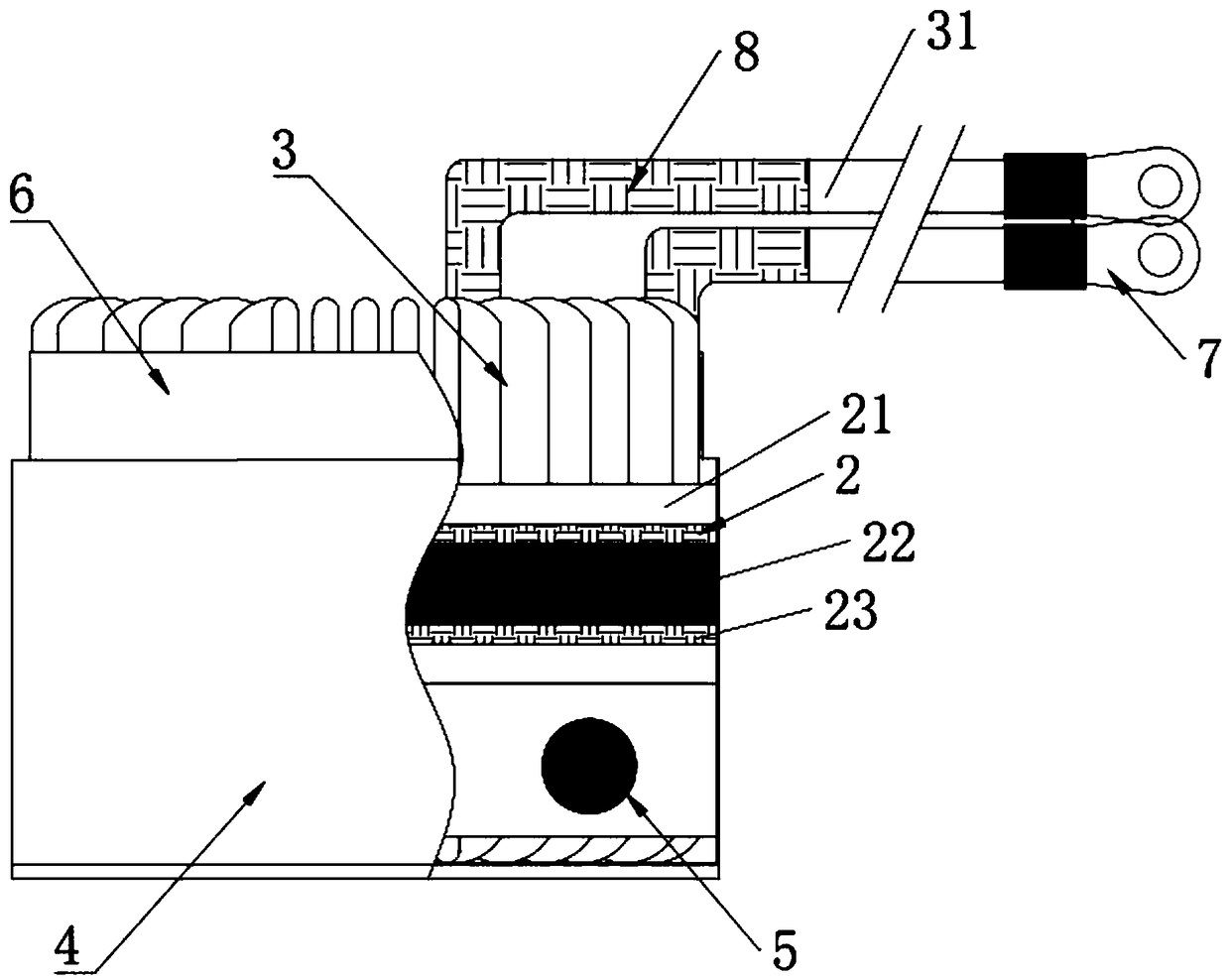

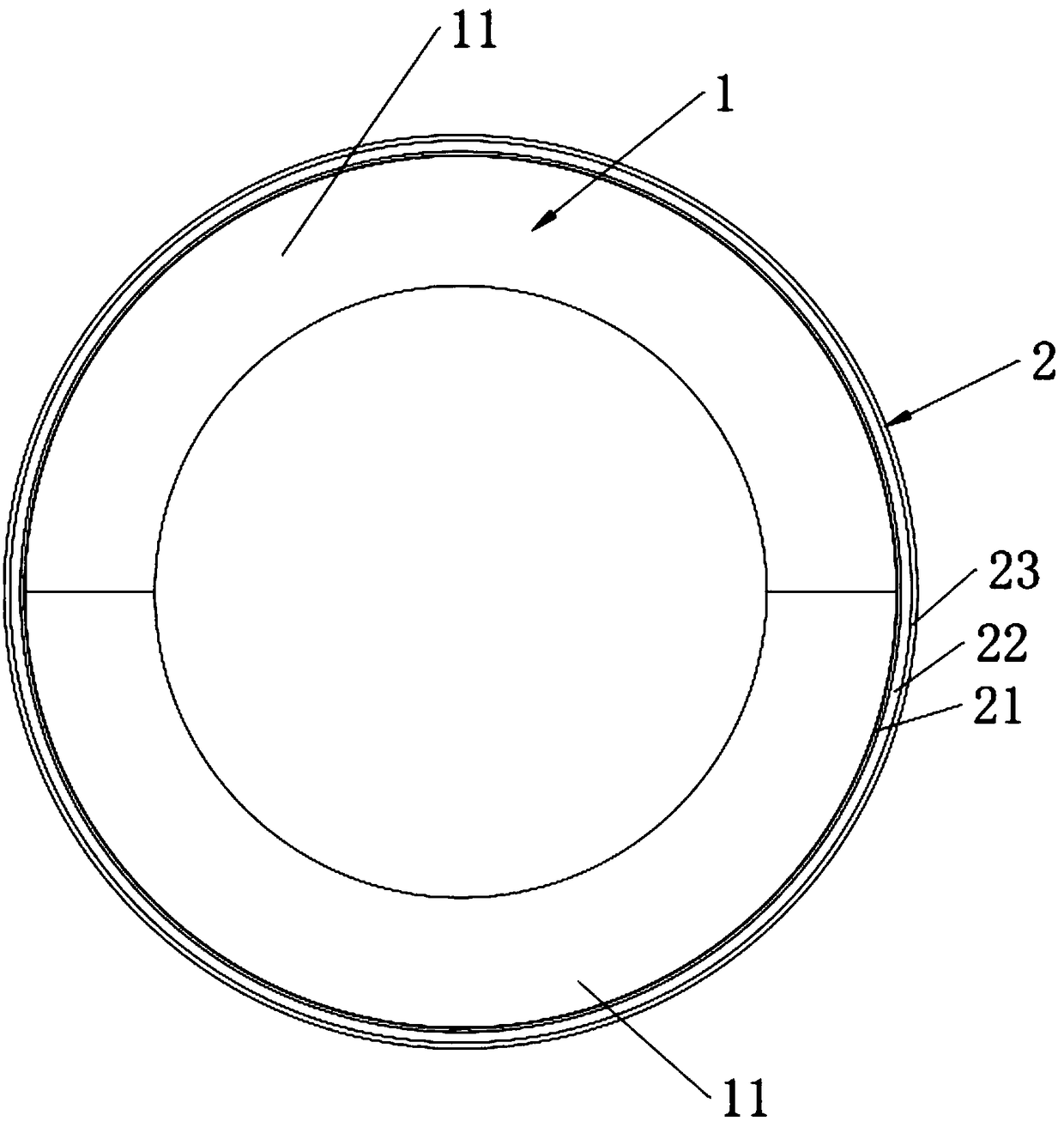

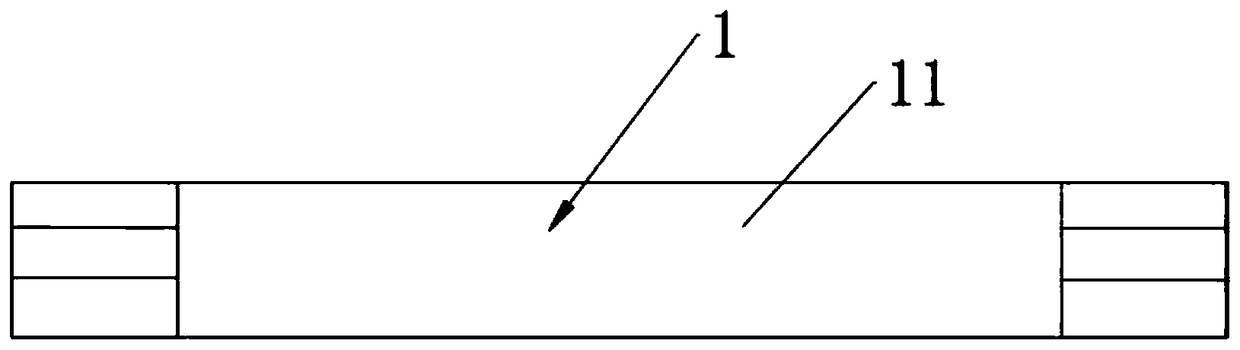

[0041] refer to Figure 1 to Figure 3 , figure 1 It is a structural schematic diagram of the novel PFC inductor in embodiment 1, figure 2 It is a top view of the combined magnetic core and insulating fixture in Embodiment 1, image 3 It is a cross-sectional view of the combined magnetic core in Embodiment 1. The new PFC inductor in this embodiment includes a combined magnetic core 1 , an insulating fixture 2 , a flat copper wire 3 , an aluminum box 4 , a thermally conductive silica gel 5 , a third insulating paper 6 , a crimping terminal 7 and a high-temperature-resistant heat-shrinkable sleeve 8 .

[0042] The combined magnetic core 1 includes two sub-cores 11, the two sub-cores 11 are matched, and the two sub-cores 11 are correspondingly fixed. Each sub-core 11 includes successively laminated silicon-aluminum core layers and iron-silicon core layers. In this embodiment, the thickness of the sendust core layer is 1 to 2 times the thickness of the iron-silicon core layer. ...

Embodiment 2

[0052] refer to Figure 4 , Figure 4 It is a flow chart of the method for preparing a novel PFC inductor in Example 2, and the method for preparing a novel PFC inductor in this embodiment includes the following steps:

[0053] A combined magnetic core 1 is produced, and the combined magnetic core 1 includes two matched sub-magnetic cores 11 . The step of making the combined magnetic core 1 includes the following sub-steps: firstly, two sendust core layers and one sendust core layer are superimposed on each other, and then glued to form the combined magnetic core 1, and the combined magnetic core 1 is along its own Radially cut into two sub-cores 11, in this embodiment, when cutting, cut along the center of the combined magnetic core 1, so that the combined magnetic core 1 is cut into two sub-cores 11 equally divided, so that the sub-magnetic Core 11 Consistency. Specifically, the cutting of the combined magnetic core 1 can be realized by a cutting machine.

[0054] The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com