An integrated cable special for welding machine and a manufacturing method thereof

An integrated, kind of welding machine technology, applied in the direction of cable joints, insulated cables, cables, etc., can solve problems such as cable rupture, carbon dioxide leakage, and time-consuming and labor-intensive cable processes, and achieve the effect of preventing external wear and improving anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

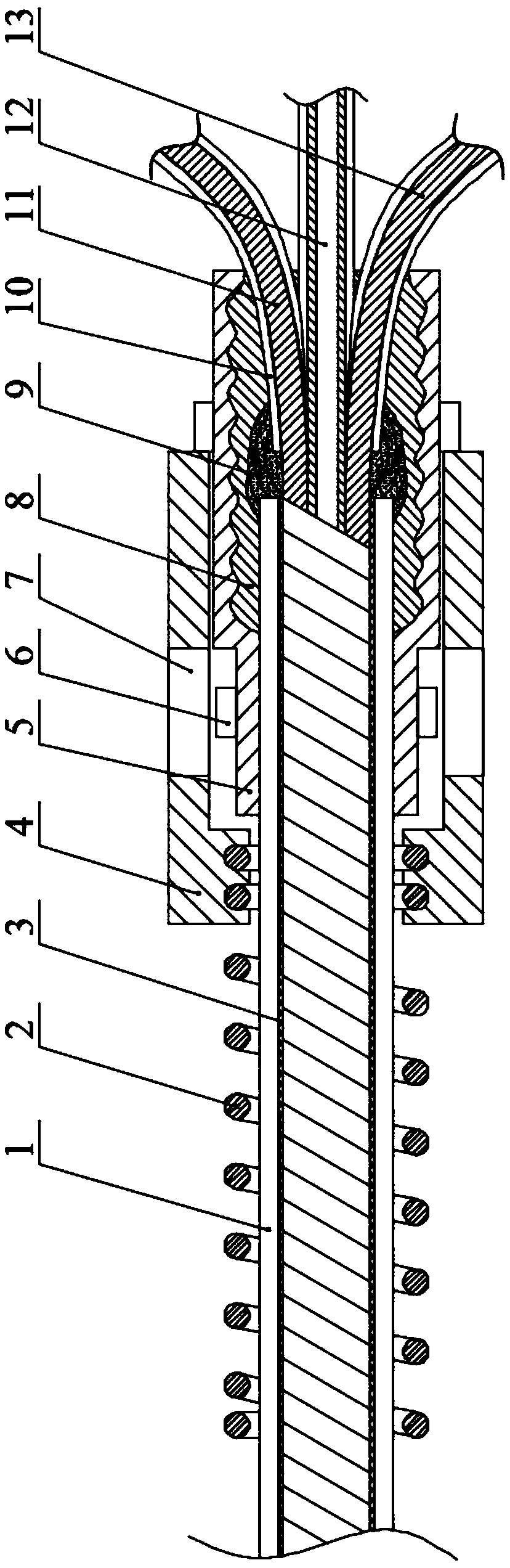

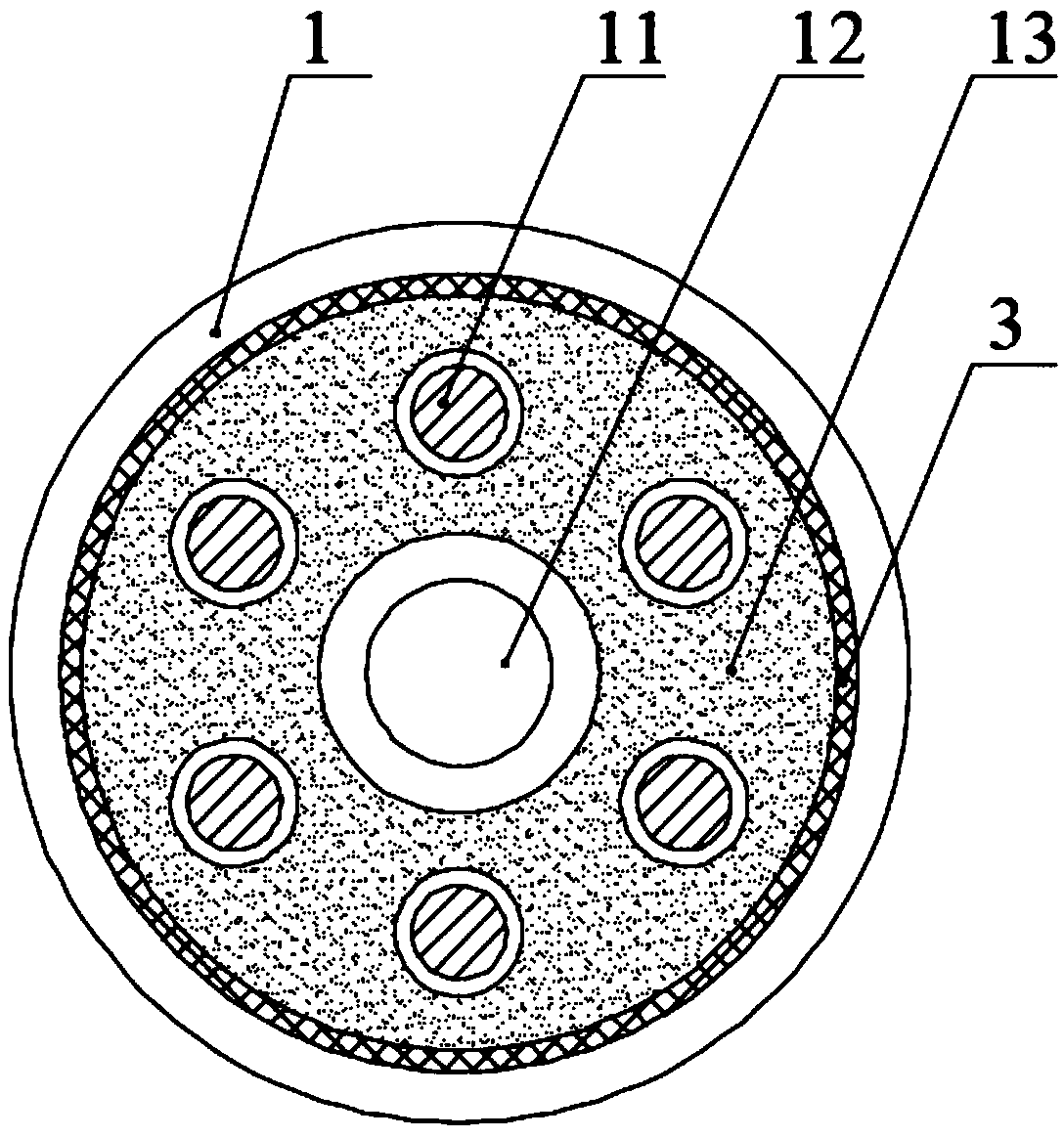

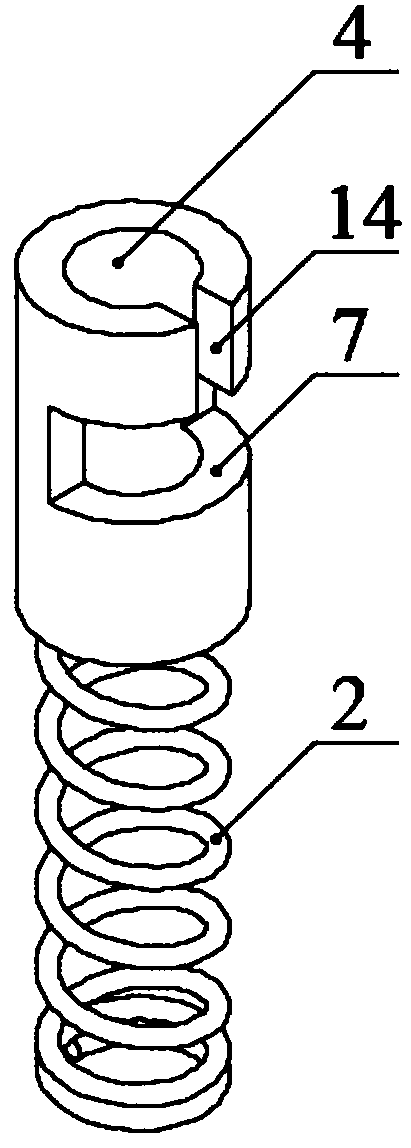

[0028] An integrated cable dedicated to welding machines, including a cable body composed of a protective sheath 1, an isolation layer 3, a control wire 11, a conductor wire 13, and a gas pipe 12, wherein the outside of the gas pipe is uniformly covered with a cable made of control wires and conductor wire harnesses The conductive layer formed after the above, the conductive layer is covered with an isolation layer, and the isolation layer is covered with a protective sleeve, and the two ends of the integrated cable are equipped with connecting joints that can be quickly disconnected from the wire feeder 15 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com