Marine low-speed diesel exhaust gas collecting tank with catalytic denitration function

A catalytic denitrification and gas collection box technology, applied in gas treatment, mechanical equipment, combustion engines, etc., can solve the problems of consumption, low utilization rate of residual heat, and low economic efficiency, so as to improve denitrification efficiency, facilitate cleaning, Efficient NOx removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

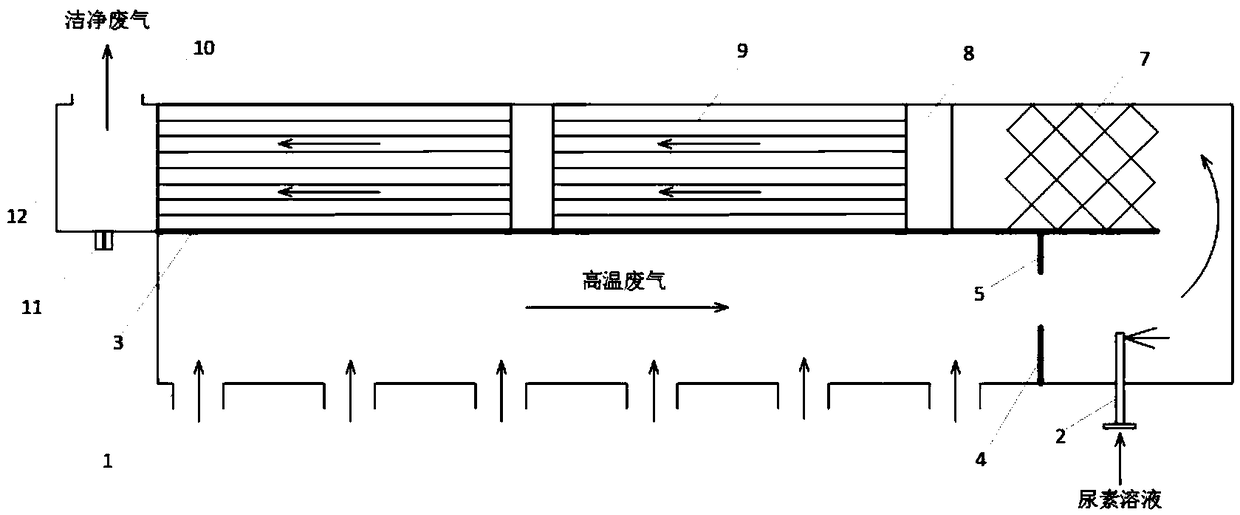

Embodiment 1

[0047] Such as figure 1 As shown: the top-mounted gas collection box adopts a square structure, and is divided into upper and lower chambers by welding the plate 3 into the gas collection box. The exhaust gas inlet 1 at the bottom of the lower chamber is connected to the exhaust manifold of each cylinder to circulate the exhaust gas, and the upper baffle 5, the lower baffle 4 and the urea injection head 2 are installed in sequence on the right side to prevent the backflow of the reaction gas. The urea injection system is connected, a static mixer 7 is arranged in the upper chamber, and a double-layer catalytic denitrification module 9 is installed. The exhaust gas outlet 10 facing upward on the left side is connected to the turbine, and a soot blower 12 is installed at the lower end of the exhaust gas outlet.

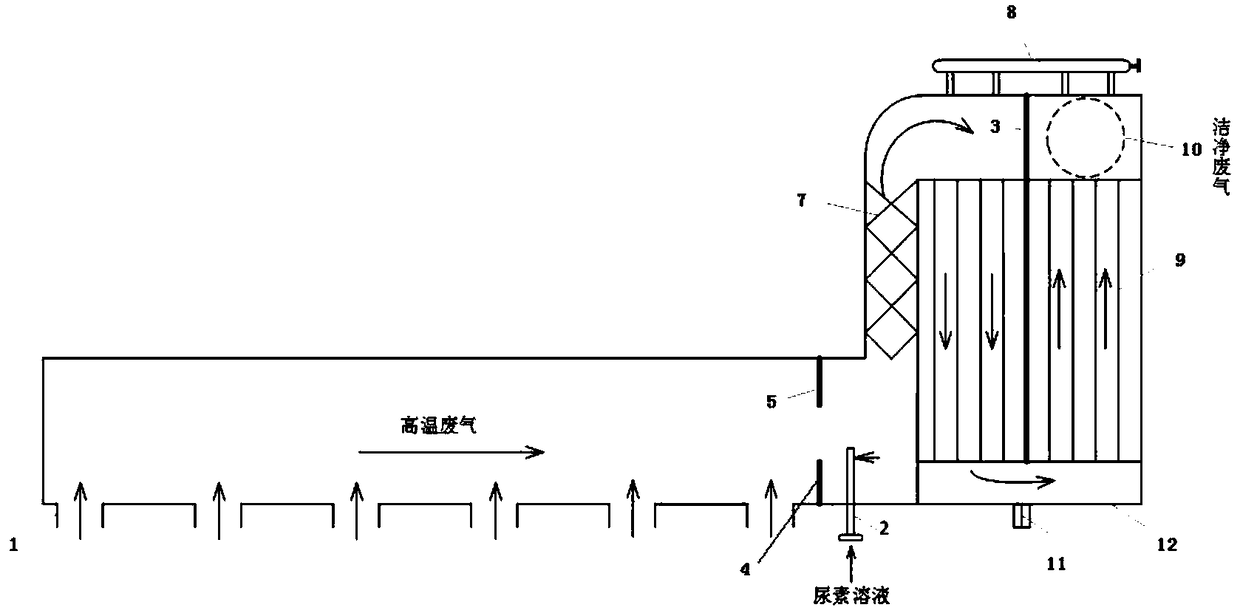

Embodiment 2

[0049] Such as figure 2 Shown: a side-mounted gas collection box, the left chamber adopts a square structure, and the bottom exhaust gas inlet 1 is connected to the exhaust manifold of each cylinder to circulate the exhaust gas. The baffle 4 and the urea injection head 2; the right chamber also adopts a square structure, the inlet is arranged with a static mixer 7, and then a double-layer catalyst module 9 is arranged, and the double-layer catalyst module 9 is divided into two pieces by the plate 3 to deflect the exhaust gas , improve denitrification efficiency. The exhaust gas outlet 10 connected to the turbine and the soot blowing system 8 are arranged above the right chamber, and the soot blowing box 12 is arranged below the right chamber.

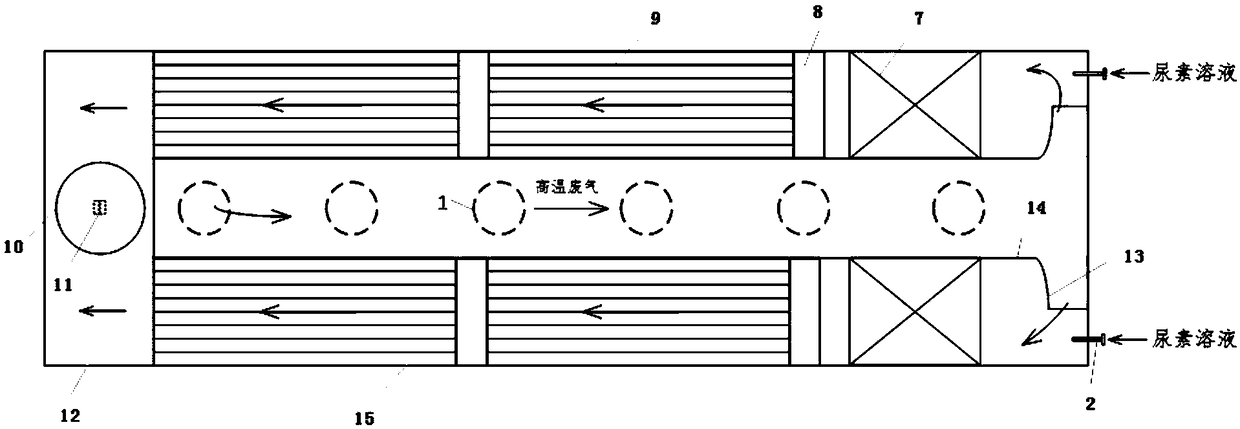

Embodiment 3

[0051] Such as Figure 3-4 As shown: the ring-mounted gas collection box adopts a circular structure, the inner circular pipe 14 is arranged in the center of the gas collection box, and its bottom is connected with the exhaust manifold of each cylinder, and the tail end of the inner circular pipe 14 adopts the structure of an elbow 13 , waste gas is passed into the outer circular pipe 15. The urea injection head 2 and the static mixer 7 are sequentially installed behind the exhaust gas outlet of the inner circular pipe 14; the outer circular pipe 15 is arranged with an annular denitrification module. The outlet of the exhaust gas of the outer circular pipe 15 opens upwards to prevent the outflow of exhaust gas from entering the turbine with debris; the soot blowing system 8 is arranged on the upper layer of the denitrification module, which can be cleaned regularly.

[0052] In summary: the purpose of the present invention is to provide a marine low-speed diesel engine exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com