Preparation method of cobalt nitrogen co-doped biomass carbon oxidation reduction catalyst

A biomass carbon, co-doping technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems that hinder the commercial application of large-scale equipment, poor stability and methanol resistance, and easy fuel. Penetration and other problems, to achieve the effect of low price, good methanol resistance and stability, and ORR performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for co-doping biomass carbon with cobalt and nitrogen to improve the performance of redox catalysts. The preparation of biomass porous carbon materials: using fresh kelp as raw material, freezing with liquid nitrogen, putting it into a vacuum dryer for drying, and crushing through 20 meshes after drying Sieve for use; take the pulverized kelp and add a certain amount of potassium hydroxide to grind and mix thoroughly, put it in a porcelain boat and place it in a high-temperature furnace with a nitrogen flow rate of 1L / min and a heating rate of 5°C / min, and set a certain activation temperature and activation time; after activation The sample was first washed with 10% hydrochloric acid, then washed with deionized water until neutral, and dried by suction to obtain the final sample. Preparation of cobalt nitrogen co-doped biomass porous carbon material: First, take 20 mg of optimized biomass activated carbon, add 6 mL of deionized water to stir and disperse, after ...

Embodiment 2

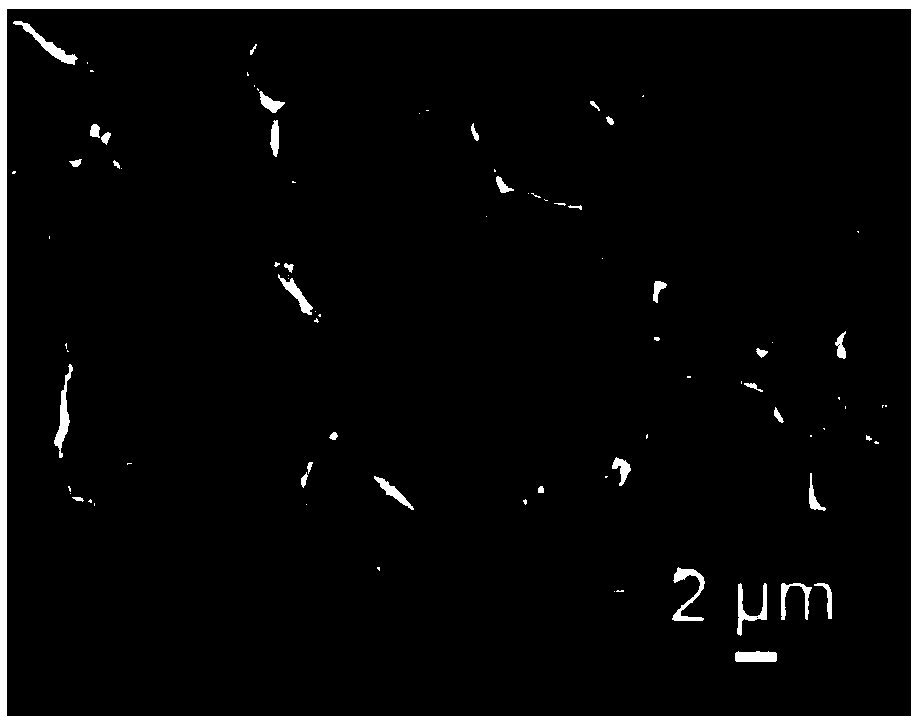

[0028] A method for co-doping biomass carbon with cobalt and nitrogen to improve the performance of redox catalysts. The preparation of biomass porous carbon materials: using fresh kelp as raw material, freezing with liquid nitrogen, putting it into a vacuum dryer for drying, and crushing through 20 meshes after drying Sieve for use; take the pulverized kelp and add a certain amount of potassium hydroxide to grind and mix thoroughly, put it in a porcelain boat and place it in a high-temperature furnace with a nitrogen flow rate of 1L / min and a heating rate of 5°C / min, and set a certain activation temperature and activation time; after activation The sample was first washed with 10% hydrochloric acid, then washed with deionized water until neutral, and dried by suction to obtain the final sample. Preparation of cobalt nitrogen co-doped biomass porous carbon material: First, take 20 mg of optimized biomass activated carbon, add 6 mL of deionized water to stir and disperse, after ...

Embodiment 3

[0030]A method for co-doping biomass carbon with cobalt and nitrogen to improve the performance of redox catalysts. The preparation of biomass porous carbon materials: using fresh kelp as raw material, freezing with liquid nitrogen, putting it into a vacuum dryer for drying, and crushing through 20 meshes after drying Sieve for use; take the pulverized kelp and add a certain amount of potassium hydroxide to grind and mix thoroughly, put it in a porcelain boat and place it in a high-temperature furnace with a nitrogen flow rate of 1L / min and a heating rate of 5°C / min, and set a certain activation temperature and activation time; after activation The sample was first washed with 10% hydrochloric acid, then washed with deionized water until neutral, and dried by suction to obtain the final sample. Preparation of cobalt nitrogen co-doped biomass porous carbon material: First, take 20 mg of optimized biomass activated carbon, add 6 mL of deionized water to stir and disperse, after 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com