Method for preparing nanocrystalline WC-Co hard alloy through amorphous crystallization

A cemented carbide and nanocrystalline technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficult preparation of ceramic-based amorphous precursor materials and preparation of nanocrystalline cemented carbide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

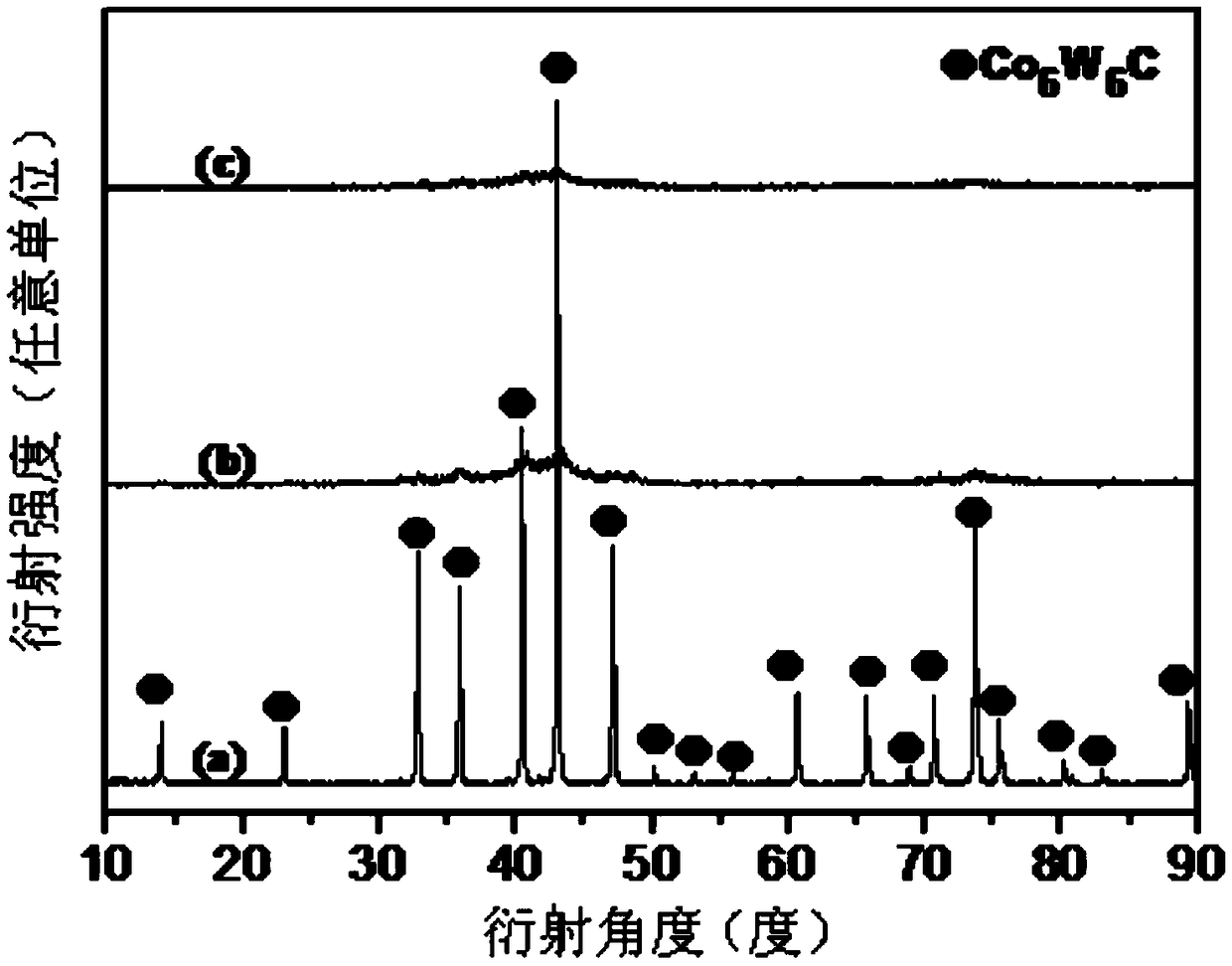

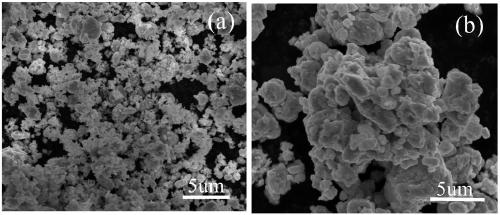

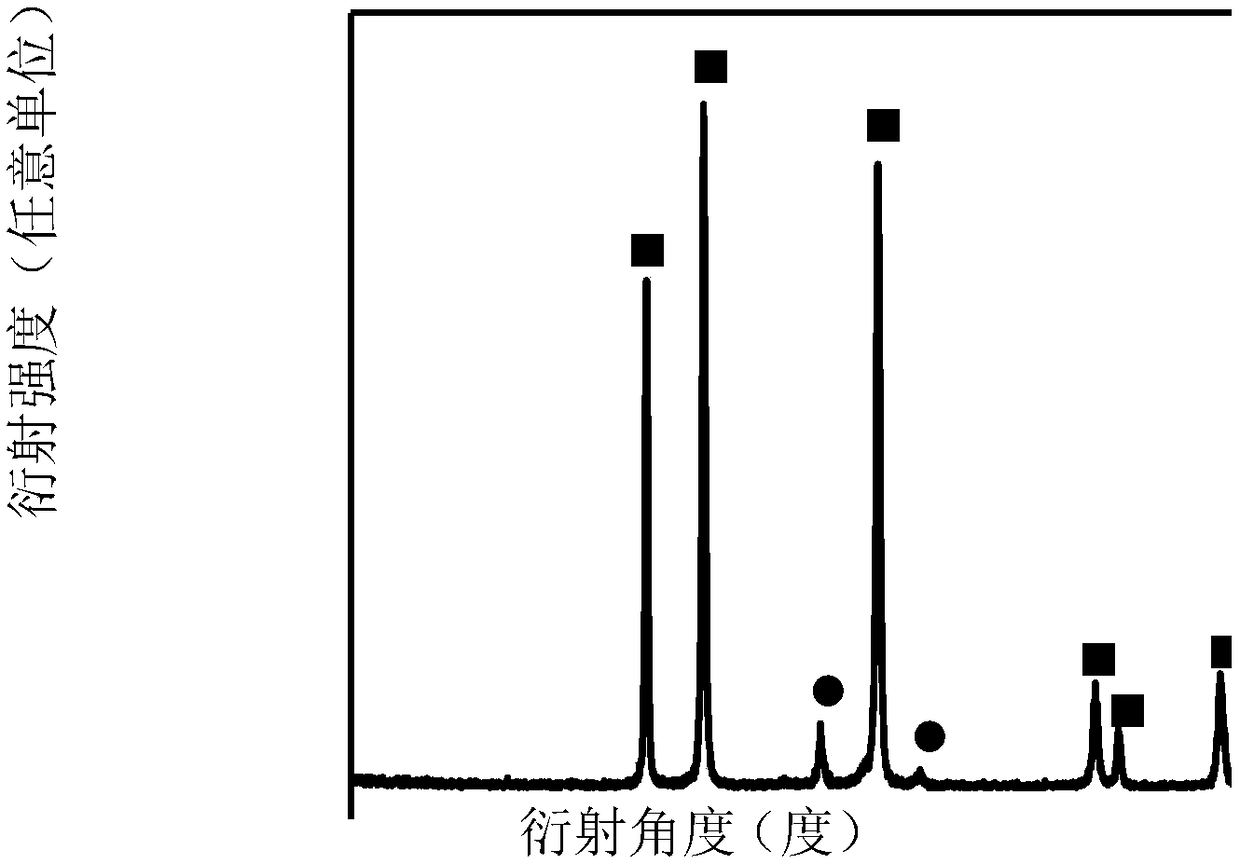

[0021] The ternary compound Co with an average particle size of about 300nm was prepared in batches with the applicant's existing authorized patent technology (authorized patent number: CN201510491451.4) 6 W 6 C powder is used as a raw material, and is added into a cemented carbide ball milling tank together with cemented carbide balls, and four kinds of cemented carbide grinding balls with diameters of 4mm, 5mm, 8mm and 10mm are loaded into each tank, and the mass ratio is 2:2:4:2, using argon as a protective atmosphere, cemented carbide grinding balls and ternary compound Co 6 W 6 The weight ratio of C is 18:1, the ball milling time is 70 hours, the ball milling speed is 600r / min, and amorphous Co is obtained after ball milling. 6 W 6 C powder; for the prepared amorphous Co 6 W 6 C powder is tested for carbon content, and the measured carbon content is 1.10wt.%, according to the reaction formula Co 6 W 6C+5C=6WC+6Co add corresponding carbon black 4.90wt.%, so that the...

Embodiment 2

[0024] The ternary compound Co with an average particle size of about 500nm was prepared in batches with the applicant's existing authorized patent technology (authorized patent number: CN201510491451.4) 6 W 6 C powder is used as a raw material, and is added into a cemented carbide ball milling tank together with cemented carbide balls, and four kinds of cemented carbide grinding balls with diameters of 4mm, 5mm, 8mm and 10mm are loaded into each tank, and the mass ratio is 2:2:4:2, using argon as a protective atmosphere, cemented carbide grinding balls and ternary compound Co 6 W 6 The weight ratio of C is 22:1, the ball milling time is 65 hours, the ball milling speed is 550r / min, and amorphous Co is obtained after ball milling. 6 W 6 C powder; for the prepared amorphous Co 6 W 6 C powder is tested for carbon content, and the measured carbon content is 1.20wt.%, according to the reaction formula Co 6 W 6 C+5C=6WC+6Co add corresponding carbon black 5.30wt.%, so that th...

Embodiment 3

[0027] The ternary compound Co with an average particle size of about 400nm was prepared in batches with the applicant's existing authorized patent technology (authorized patent number: CN201510491451.4) 6 W 6 C powder, using it as raw material, is added to the cemented carbide ball milling tank together with cemented carbide balls, and four kinds of cemented carbide grinding balls with diameters of 4mm, 5mm, 8mm and 10mm are loaded into each tank, and the mass ratio is 2:2:4:2, using argon as a protective atmosphere, cemented carbide grinding balls and ternary compound Co 6 W 6 The weight ratio of C is 25:1, the ball milling time is 55 hours, the ball milling speed is 500r / min, and amorphous Co is obtained after ball milling. 6 W 6 C powder; for the prepared amorphous Co 6 W 6 C powder is tested for carbon content, and the measured carbon content is 1.50wt.%, according to the reaction formula Co 6 W 6 C+5C=6WC+6Co add corresponding carbon black 5.40wt.%, so that the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com