Underwater closed space local dry method welding robot

A technology for welding robots and confined spaces, which is applied in welding equipment, welding equipment, welding accessories, etc., and can solve problems such as high pressure and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

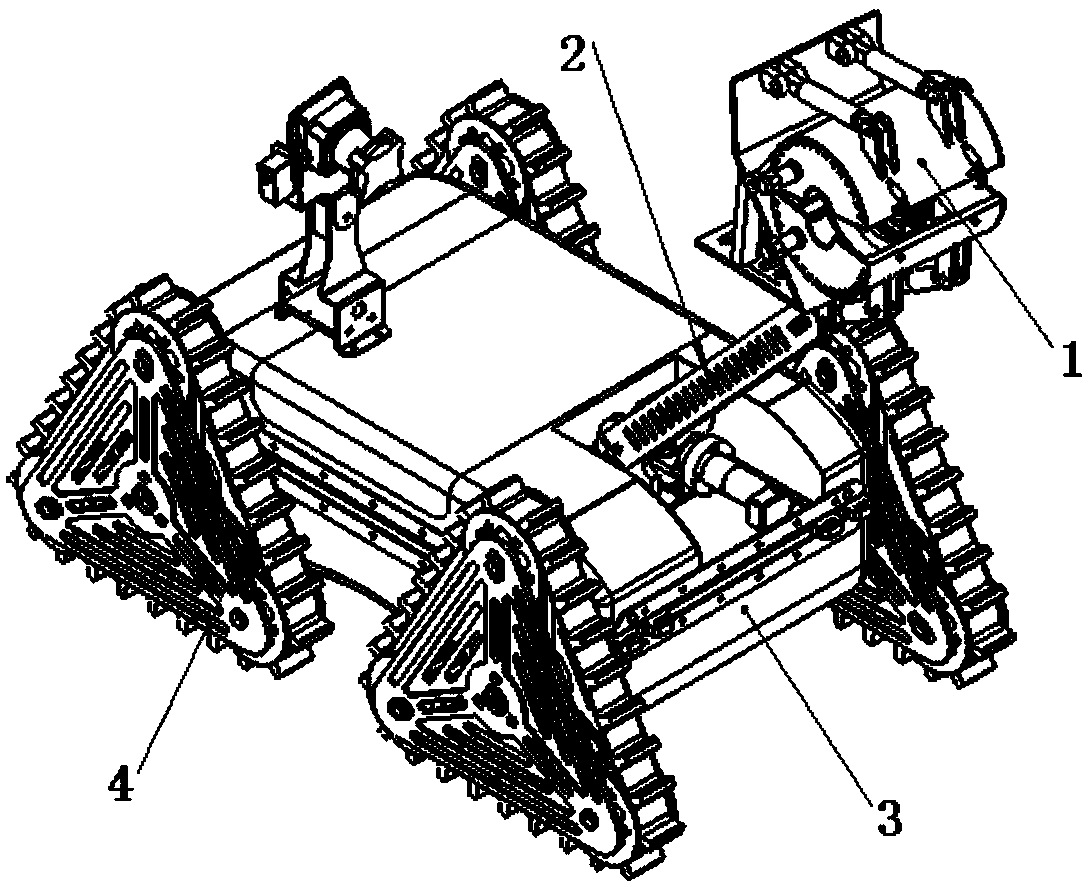

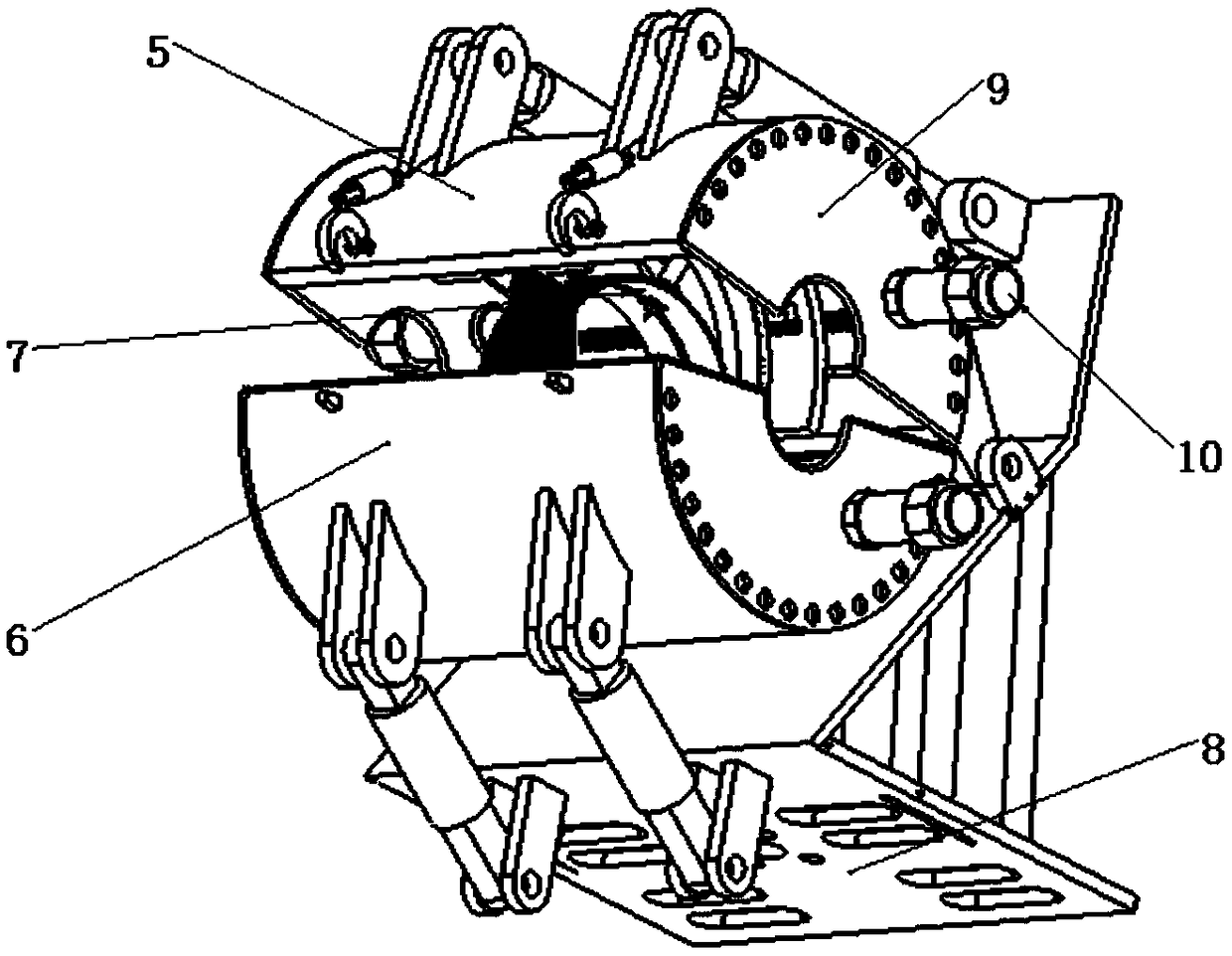

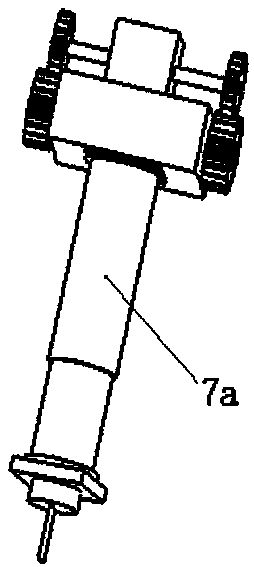

[0027] In a nutshell, this kind of underwater confined space local dry welding robot includes a walking mechanism, a mechanical operating arm mechanism, a slider sliding mechanism, a welding gun moving mechanism and a hydraulic system. The walking mechanism includes a robot shell and a walking triangular track wheel. .

[0028]Wherein, the robot housing is in the shape of a cuboid box, and the housing itself adopts a layered form, consisting of an upper pressure-resistant housing and a lower pressure-resistant housing. The lower half is equipped with a motion mechanism, and the upper half is equipped with electronic components and detection equipment. Equipment and power equipment, the upper and lower parts are completely separated, the two pressure-resistant shells are equipped with electronic components, testing instruments, etc., a detachable head is placed between the pressure-resistant shells, and the electronic devices and instruments in the shell . The sealing between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com