Protective composite material and preparation method thereof

A technology of composite materials and protective layers, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc. Sub-radiation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

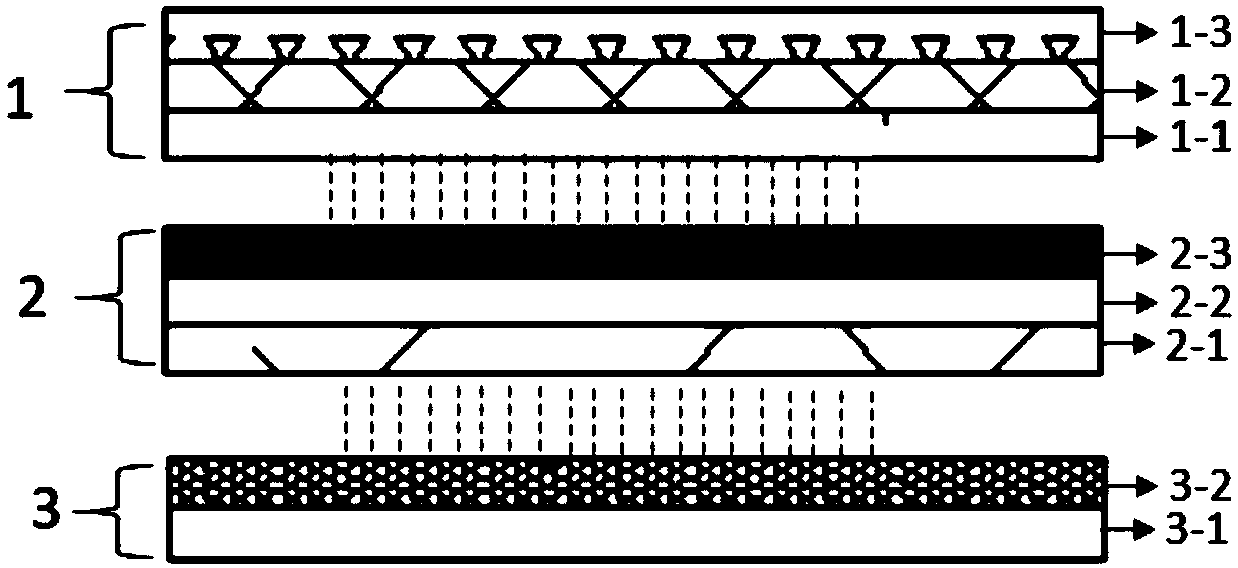

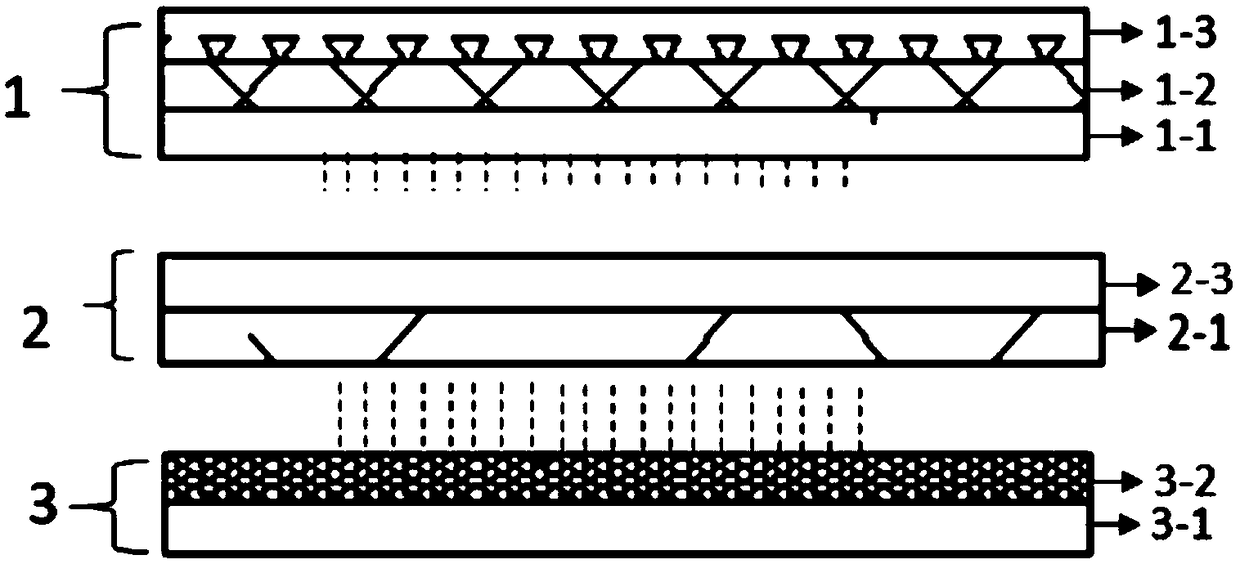

[0046] The application also provides a preparation method for the protective composite material, comprising the following steps:

[0047] An electromagnetic shielding functional layer is compounded on the surface of the fabric substrate, and a nuclear radiation protective shielding paint is coated on the surface of the electromagnetic shielding functional layer to obtain a functional layer; or, a nuclear radiation protective shielding paint is coated on the surface of the fabric substrate to obtain a functional layer;

[0048] Scrape-coat neutron protective paint on the surface of polypropylene polymer substrate to obtain a comfortable layer;

[0049] The protection layer, the functional layer and the comfort layer are combined, and the protection layer is in contact with the coating formed by the nuclear radiation protection shielding coating in the functional layer, and the coating formed by the neutron protection coating in the comfort layer is contacting with the fabric su...

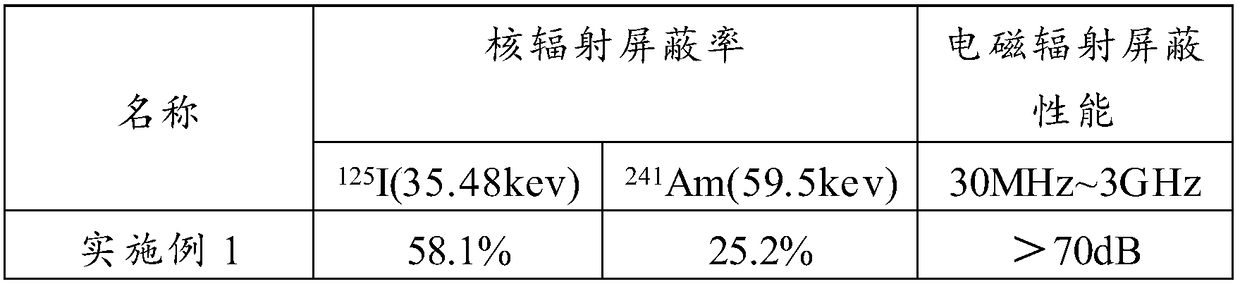

Embodiment 1

[0068] 1. The outermost layer (layer 1 - protective layer):

[0069] Prepare polyester fabric base material with antistatic function by weaving polyester filament and conductive fiber, and then use halogen-free flame retardant and water and oil repellent finishing agent to carry out flame retardant treatment and oil and water repellent treatment on the fabric in sequence through the post-finishing process; The weight of the polyester fabric base material is 80g / m 2 ;

[0070] The specific process of the flame retardant treatment is: select 30 parts by weight of zinc borate, 5 parts by weight of a dispersant, and 65 parts by weight of an aqueous polyurethane emulsion to prepare a flame retardant coating, and then use a scraping process to perform flame retardant treatment on the surface of the fabric;

[0071] Coat the upper surface of the flame-retardant treated material with an acrylic fluoropolymer finishing agent, so as to reduce the penetration of water molecules and oil ...

Embodiment 2

[0083] 1. The outermost layer (layer 1 - protective layer):

[0084] The polyester fabric base material with antistatic function was prepared by weaving polyester filament and conductive fiber, and the flame retardant treatment, oil and water repellency treatment were carried out on the fabric in turn through the post-finishing process by using halogen-free flame retardant and water and oil repellent finishing agent; The weight of the fabric base material is 120g / m 2 ;

[0085] The specific process of the flame retardant treatment is: select 30 parts by weight of zinc borate, 5 parts by weight of a dispersant, and 65 parts by weight of an aqueous polyurethane emulsion to prepare a flame retardant coating, and then use a scraping process to perform flame retardant treatment on the surface of the fabric;

[0086] Coating the upper surface of the flame-retardant treated material with an acrylic fluoropolymer finishing agent can reduce the penetration of water molecules and oil m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com