Biological denitrification treatment device and method for wastewater

A technology of biological denitrification and treatment device, which is applied in sustainable biological treatment, water/sludge/sewage treatment, water pollutants, etc. Problems such as a large number of equipment, to achieve the effect of reducing the number of moving equipment, reducing complexity, and simplifying the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

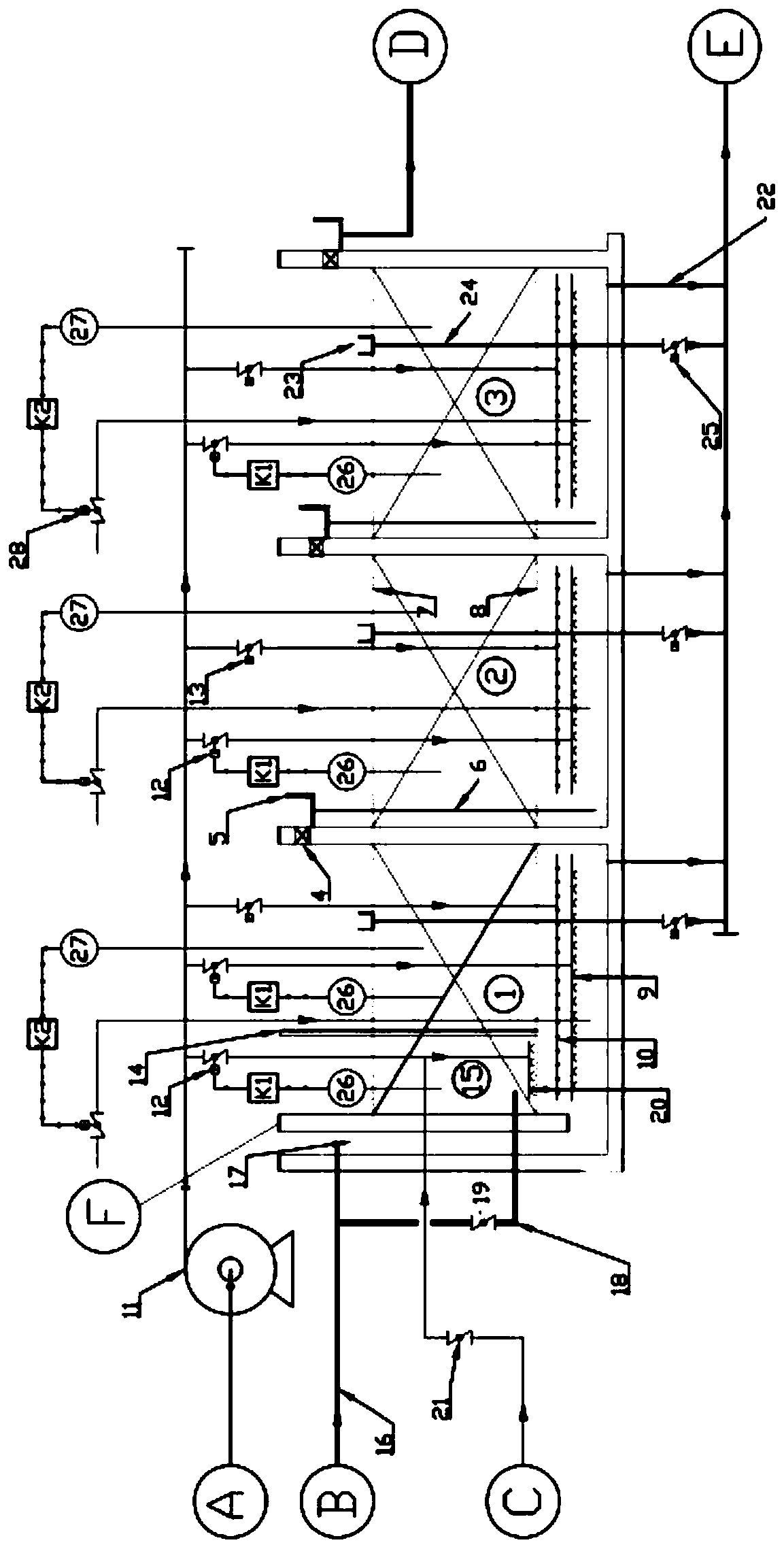

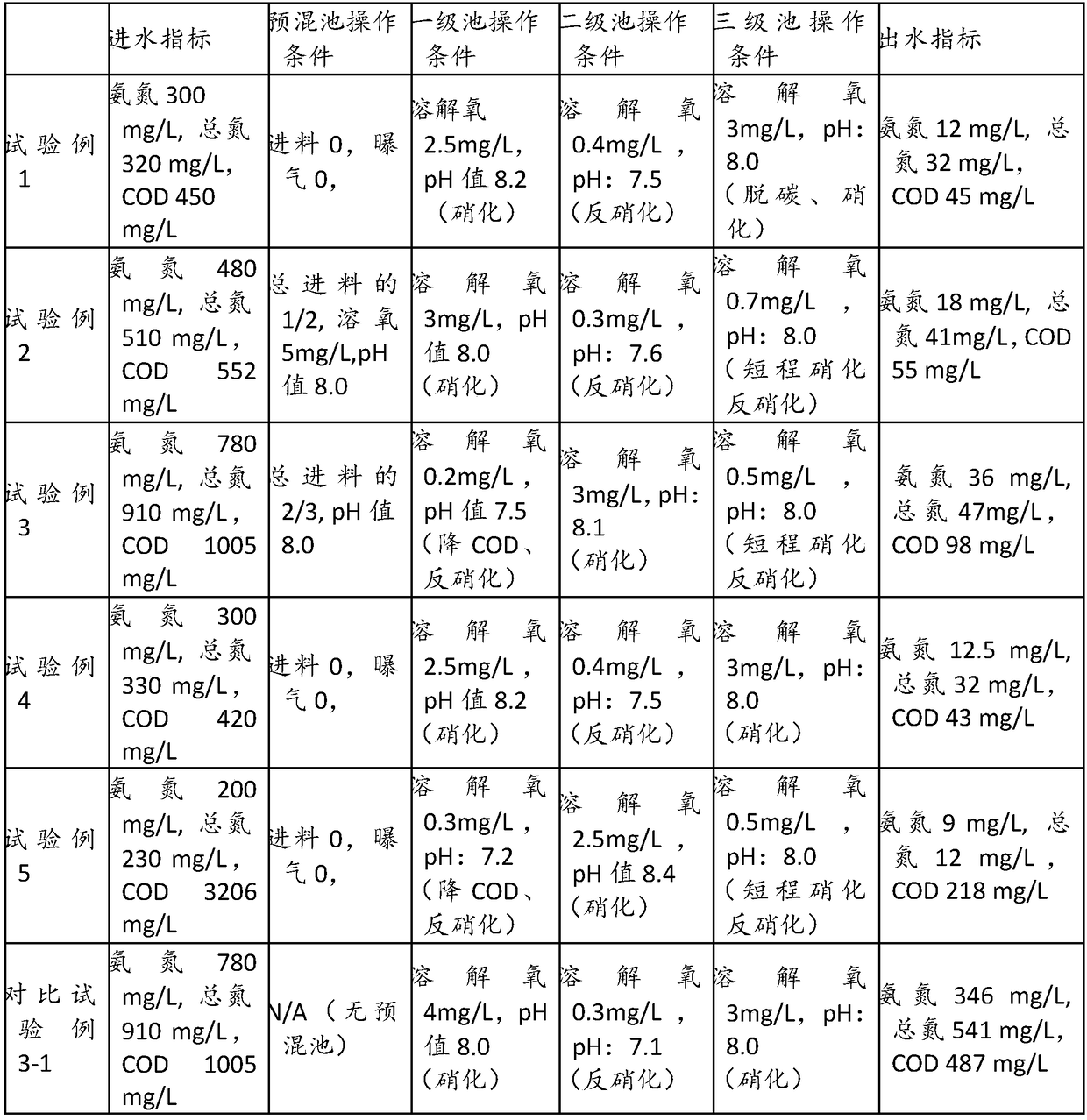

[0057] combine figure 1 As shown, a biological denitrification treatment device for wastewater includes three-stage series reaction pools 1 / 2 / 3, and the top of the partition wall at the end of each reaction pool is provided with a water outlet 4, and the height of the water outlet 4 is lower than that of the reaction pool. The water outlet 4 is provided with a water distribution tank 5; the water tank 5 is provided with a water diversion pipe 6, and for the first and second reaction tanks 1 / 2, the water diversion pipe 6 is used to guide the waste water to the bottom of the next reaction tank , so as to ensure that the waste water enters from the bottom of each level of reaction pool and is discharged from the top. The water tank is connected with the water outlet pipeline, and the treated waste water D is sent out to the device);

[0058] The reaction pool 1 / 2 / 3 of any stage is divided into a reaction area in the middle of the pool body by at least two layers of horizontally ...

Embodiment 2

[0065] In this embodiment, on the basis of Embodiment 1 or its preferred example, a premixing tank 15 is also added in the first-stage reaction tank 1; Water branch pipe 18, the water inlet branch pipe 18 is controlled by a branch valve 19;

[0066] In this embodiment, a premixed tank structure is added in the primary reaction tank, which can effectively alleviate the impact of sudden changes in water quality on the downstream system.

[0067] As a preferred embodiment, the outlet of the water inlet branch pipe 18 is located on the upper side of the lower metal mesh support 8, and a premixing tank aeration pipe 20 is provided below the outlet of the water inlet branch pipe 18, and the premixing tank is aerated. An aeration valve 12 is also provided on the pipe 20 .

[0068] The premix tank aeration pipe 20 in this preferred example is used to centrally aerate the wastewater at the outlet of the water inlet branch pipe 18, and promote the uniform mixing of the wastewater and f...

Embodiment 3

[0072] In this embodiment, on the basis of Embodiments 1 and 2, a dissolved oxygen meter 26 is also provided in the premixing tank 15 and any one of the reaction tanks, and the dissolved oxygen meter 26 and the aeration valve 12 form a dissolved oxygen control loop K1 The dissolved oxygen meter 26 is directly in contact with the water body in each reaction tank, and directly monitors and displays the dissolved oxygen concentration in each reaction tank; the dissolved oxygen concentration in the tank can be adjusted by controlling the aeration valve 12 in the dissolved oxygen control loop K1;

[0073] In the premix tank 15 and any one-stage reaction tank, a pH meter 27 and a dosing regulating valve 28 are also set to form an acid-base control loop K2 ( figure 1 Because the typesetting position is limited, the acid-base control loop in the premixing tank is not drawn); the pH meter 27 is directly in contact with the water body in each reaction tank, and the pH in each reaction ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com