A recyclable sludge sludge water separation material and its application

A mud-water separation and sludge technology, applied in sewage/sludge fertilizer, water/sludge/sewage treatment, application, etc., can solve the problems of plant root rot, consumption of mineral resources, high concentration of aluminum ions, etc., and achieve a well-developed plant root system , high water transparency and large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

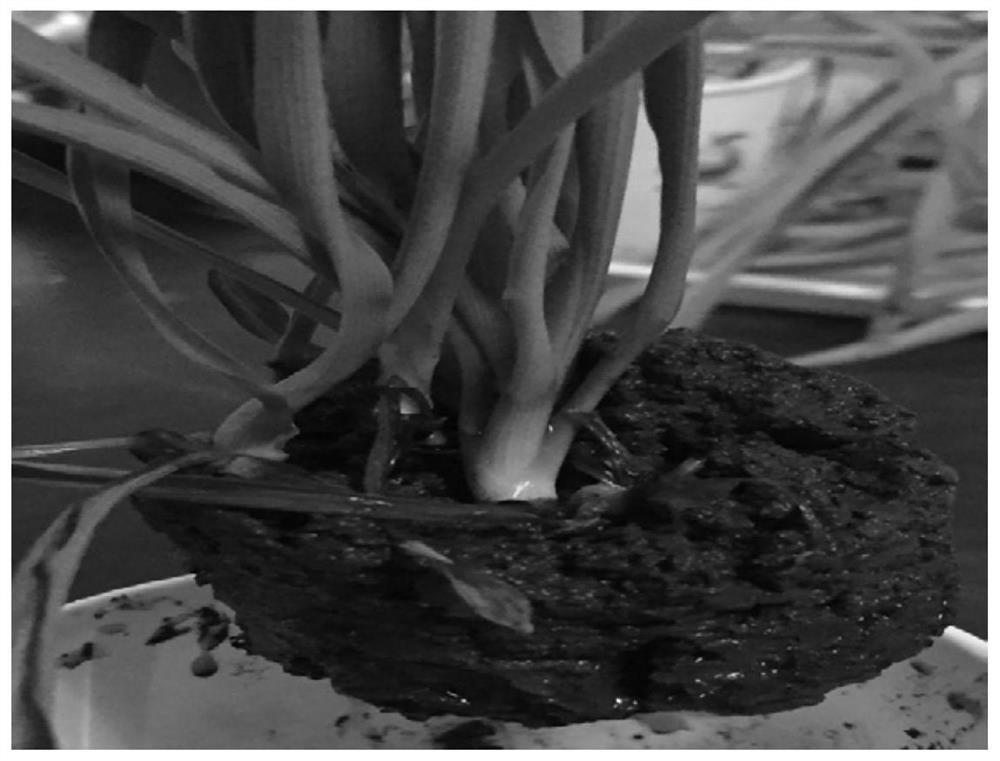

Image

Examples

Embodiment 1

[0028] According to the mass ratio of 35:15:7.5:7.5:50, weigh the zeolite powder, corn stalks (filtered through a 10-mesh sieve), calcium carbonate, diatomaceous earth, and MT, and mix them evenly.

[0029] Take 1000ml of a certain municipal sludge, add 60g of the above mud-water separation material, stir evenly, let it stand for 5 minutes, press filter for dehydration, and test the transparency of the effluent. The results are shown in Table 1. Take 1000ml of sludge from the same source, add 60g of existing mud-water separation materials on the market, stir evenly, let stand for 5 minutes, press filter for dehydration, and test the transparency of the effluent. The results are shown in Table 1. It can be seen from the comparison that after conditioning by the material of the present invention, the transparency of the filter press effluent is higher than that of the sludge effluent conditioned by the existing material, indicating that the material of the present invention is mo...

Embodiment 2

[0031] According to the mass ratio of 35:15:7.5:7.5:0.4:0.1:50, weigh corncob ash, cottonseed hulls (the crushed material is filtered through a 10-mesh sieve), magnesium oxide, gypsum, BFA, magnesium carbonate, and MT and mix them evenly.

[0032] Take 1000ml of the sludge used in Example 1, add 60g of the above-mentioned mud-water separation material, stir evenly, let stand for 5 minutes, press filter for dehydration, and test the transparency of the effluent, the results are shown in Table 1. Compared with the transparency of sludge effluent conditioned by existing mud-water separation materials on the market, it can be seen that the transparency of sludge press-filtered water conditioned by patented materials is higher, indicating that the material of the present invention is more conducive to mud-water separation than existing mud-water separation materials on the market. The mud and water are separated more thoroughly. The dehydrated sludge is planted with Chlorophytum, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com