Toy mud and preparation method thereof

A technology for toy mud and viscous substances, applied in the field of toy mud and its preparation, can solve the problems of easy drying, hardening, cracking, etc., and achieve the effects of improving usable life, strong plasticity, and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

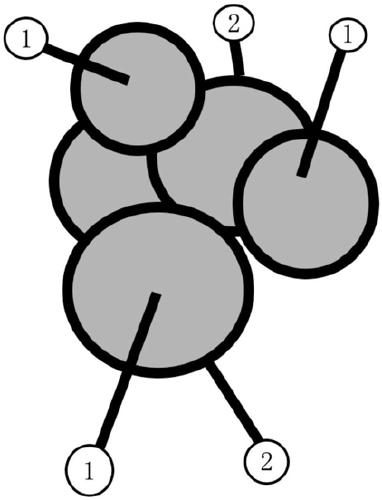

Image

Examples

preparation example Construction

[0027] In addition, for the toy slime of the present invention, the applicant specifically provides a preparation method, comprising the following steps:

[0028] S1: Mix hydrogenated styrene-butadiene block copolymer and methyl methacrylate in proportion, heat at 175-185°C for 2-4 hours to obtain a viscous substance; then add white oil and beeswax and stir evenly.

[0029] S2: When the product of S1 is stirred to a slurry state, add diatomaceous earth and silicon dioxide and continue stirring until uniform.

[0030] S3: Add remaining raw material components to the product of S2 and stir evenly to obtain toy slime.

[0031] Describe below in conjunction with specific implementation manner:

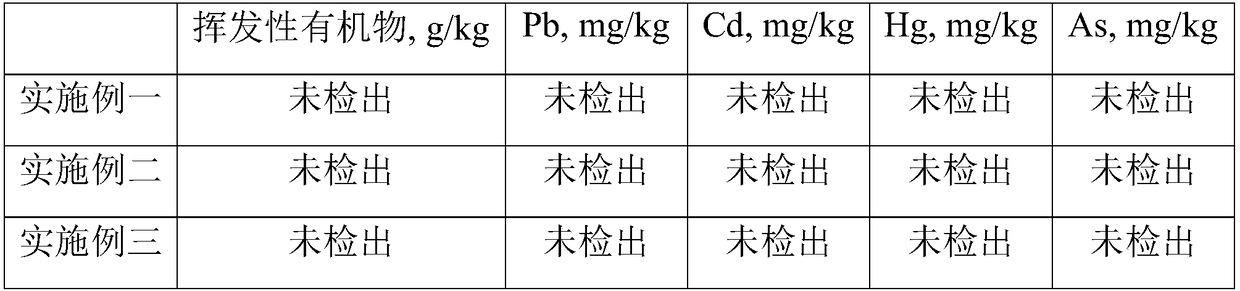

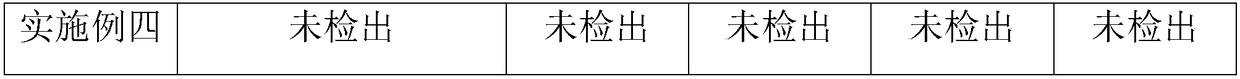

Embodiment 1

[0033] This embodiment provides a kind of toy slime, and the raw material components are calculated in parts by mass, including: 72 parts of nano silicon dioxide, 3 parts of diatomaceous earth, 20 parts of hydrogenated styrene-butadiene block copolymer, methyl methacrylate 1 part of ester, 0.36 part of polyethylene glycol, 2.1 parts of beeswax, 1 part of sorbitol, 1 part of white oil, 0.2 part of environmentally friendly fluorescent organic pigment for plastics and 0.02 part of sodium dehydroacetate antibacterial agent.

[0034] The toy slime is prepared by using the above-mentioned raw material components, comprising the following steps:

[0035] S1: Mix hydrogenated styrene-butadiene block copolymer and methyl methacrylate in proportion, heat at 180° C. for 3 hours to obtain a viscous substance; then add white oil and beeswax and stir evenly.

[0036] S2: When the product of S1 is stirred to a slurry state, add diatomaceous earth and silicon dioxide and continue stirring unt...

Embodiment 2

[0039] This embodiment provides a kind of toy slime, the raw material components are calculated in parts by mass, including: 100 parts of nano silicon dioxide, 1 part of diatomaceous earth, 19 parts of hydrogenated styrene-butadiene block copolymer, methyl methacrylate 1 part of ester, 0.01 part of polyethylene glycol, 3 parts of beeswax, 0.1 part of sorbitol, 2 parts of white oil, 0.01 part of environmentally friendly fluorescent organic pigment for plastics and 0.1 part of sodium dehydroacetate antibacterial agent.

[0040] The toy slime is prepared by using the above-mentioned raw material components, comprising the following steps:

[0041] S1: Mix the hydrogenated styrene-butadiene block copolymer and methyl methacrylate in proportion, heat at 185°C for 2 hours to obtain a viscous substance; then add white oil and beeswax and stir evenly.

[0042]S2: When the product of S1 is stirred to a slurry state, add diatomaceous earth and silicon dioxide and continue stirring until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com